Экранирующая медная проволочная сетчатая ткань с электромагнитными

- Категории: >>>

- Поставщик: Shenzhen,Huntoo,Technology,Co.,Ltd.Shenzhen,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Features

1.Root-blocking property: It can effectively prevent plant roots.

2.Waterproof: Has good waterproof performance.

3.Corrosion Resistance: Can withstand certain corrosion.

4. Stability: Maintain stable performance in different environments.

5.High intensity: It has a certain intensity and is not easy to detect.

6. Use: Last for a few.

2.Waterproof: Has good waterproof performance.

3.Corrosion Resistance: Can withstand certain corrosion.

4. Stability: Maintain stable performance in different environments.

5.High intensity: It has a certain intensity and is not easy to detect.

6. Use: Last for a few.

7. Anti-aging: It can resist aging and extend its service life.

8. Easy to construct: Easy to install and formulate.

Application

1.EMI/RMF shielding mesh screen

2.Printing mesh for Electonic Industry

3. Art printing mesh for chinaware printing , glass, etc

4. Filter liquid, gas, chemical etc.

5. LED display

2.Printing mesh for Electonic Industry

3. Art printing mesh for chinaware printing , glass, etc

4. Filter liquid, gas, chemical etc.

5. LED display

6.Waterproof building, moisture-proof

7.roof greening to block roots

Product introduction

product introduction

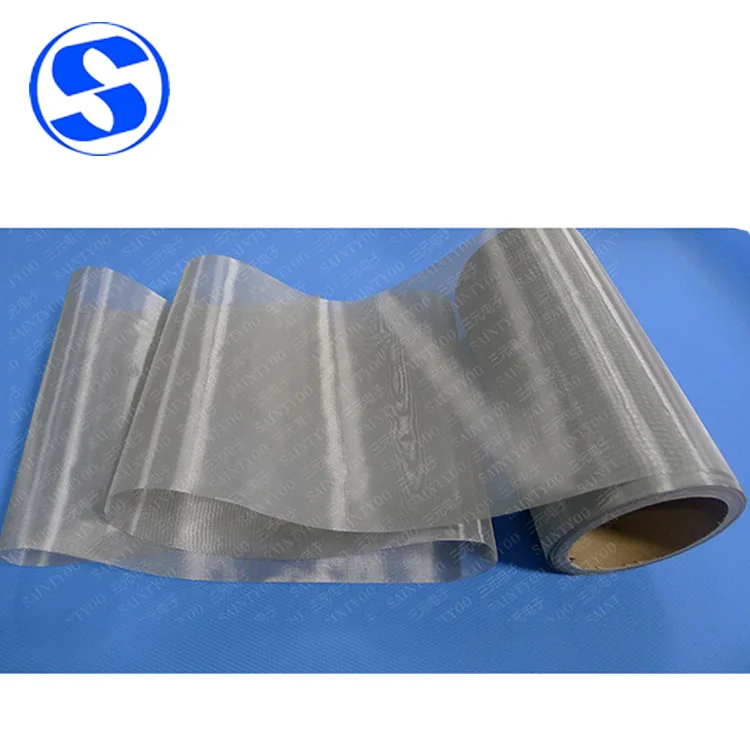

Conductive fabric is based on fibre cloth (commonly used polyester fiber cloth). After pre-treatment, plated metal coating is applied to make it have metal properties. It can be used to coat conductive pressure sensitive adhesives or bond hot melt adhesives to coat polyurethane foam cotton.

Product structure

Conductive fabric is made of polyester fibers by chemical deposition or metal physical transfer of nickel metal to polyester fibers, high conductivity copper coating on nickel, anti-oxidant nickel metal on copper coating, copper-nickel combination provides excellent conductivity and good electromagnetic shielding effect.

Application

Product testing

Recommend Products

Grid conductive pattern cloth

Diamond conductive cloth

Plain conductive fabric

Flame retardant conductive cloth

Single sided black plain conductive fabric

Colored copper nickel cloth

Company Profile

Shenzhen Huntoo Technology Co., Ltd. focuses on the research and development, production and operation of EMI and EMF shielding materials. The company was established in 2008 in Guangming District, Shenzhen City, with 8,000 square meters of fully automated production lines and various advanced equipment. The company based on its strong R&D capabilities, explores and innovates, and is committed to providing one-stop electromagnetic shielding services. It mainly operates EMF protection products, EMI shielding material products, etc. The company adheres to the principle of "quality, reputation, talents, and service-oriented", and insists on "careful management, lean production, first-class products, and first-class services". Continuously change and manage innovation to enhance comprehensive competitiveness, and is willing to have extensive cooperation with all sectors, sincerely welcome new and old customers to visit and guide, and achieve mutual benefit and win-win, and create the future together.

factory production process

The production process of conductive cloth usually includes the following steps:

1. Raw material preparation: Some suitable base materials, such as polyester fiber, etc.

2. Metal coating: Coating a metal film, such as nickel, copper, etc., on the surface of the substrate through electroplating, sputtering and other methods to improve conductivity.

3. Adhesive coating**: Apply the adhesive evenly on the metal coating.

4. DRY**: Allow the adhesive to dry to secure the metal coating.

5. Cutting and Processing**: Cut the conductive cloth into specific sizes and shapes as needed.

6. Quality Test**: Test the conductivity, adsorption capacity, etc. of the product.

7. Packaging and shipping**: Pack the qualified products and prepare them for shipment.

During the production process, the process parameters of each link need to be strictly controlled to ensure that product quality meets the requirements. At the same time, attention must be paid to the cleanliness and hygiene of the production environment to avoid product contamination.

Certifications

Packaging & Shipping

Our Advantages

Professional EMI RFID Shielding Materials Manufacturer.

Focus on the manufacturing of EMI and RFID shielding materials from 2010. Now Huntoo are the Alibaba assessed Gold supplier.

High Production Capacity And Good Quality.

Equipped with advanced facility and passed the ISO9001 certification to ensure providing customers high standard and qualified

products.

Good Service And Fast Delivery Time.

Professional Team will help and support you from each part of the transaction from Pre-sale to After-sales.

With the developing of years, HUNTOO has came to be the professional and leading EMI and RFID shielding materials manufacturer in

China

High Production Capacity And Good Quality.

Equipped with advanced facility and passed the ISO9001 certification to ensure providing customers high standard and qualified

products.

Good Service And Fast Delivery Time.

Professional Team will help and support you from each part of the transaction from Pre-sale to After-sales.

With the developing of years, HUNTOO has came to be the professional and leading EMI and RFID shielding materials manufacturer in

China

FAQ

Q1: Can I get free conductive cloth samples?

A:Yes,we are so glad to provide you with free samples.

Q2: Is there any discount?

A:Yes,for larger quantity,we always offer better price.

Q3: How to place order and make payment?

A:We are willing to accept your purchase order or a simple information by email or by TradeManager,

and we will send you proforma invoice with our bank details Paypal and L/C for your confirmation,

then you can make payment accordingly.

Q4: How about the quality guarantee ?

A:We will make 100% inspection before packing and delivery.If there is any quality problems, we will take responsibility for it.

A:Yes,we are so glad to provide you with free samples.

Q2: Is there any discount?

A:Yes,for larger quantity,we always offer better price.

Q3: How to place order and make payment?

A:We are willing to accept your purchase order or a simple information by email or by TradeManager,

and we will send you proforma invoice with our bank details Paypal and L/C for your confirmation,

then you can make payment accordingly.

Q4: How about the quality guarantee ?

A:We will make 100% inspection before packing and delivery.If there is any quality problems, we will take responsibility for it.