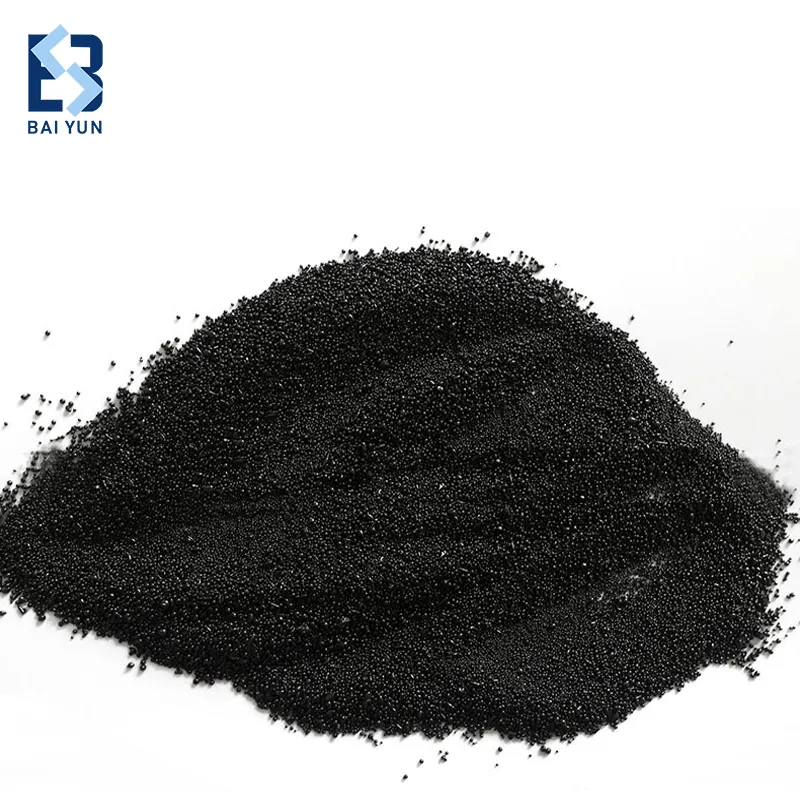

Шаг угольной смолы используется в алюминиевой и графитовой промышленности качестве связующего материала для анода производства

- Категории: >>>

- Поставщик: Hebei,Qunbang,Chemical,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

| Modified Coal Tar pitch Spec | |

| Softening point | 105-115℃ |

| Coke Value | more than 58% |

| Ash content | less than 0.3% |

| Moisture Content | less than 3% |

| TI Content | 28-34% |

| QI Content | 8-14% |

| Beta resin | more than 18% |

| Volatile Matter | less than 56% |

| Mesophase | 0 |

Normally using for Aluminum factory, Carbon factory, Refractory material factory.

| Softening point | 80-90℃ |

| Coke Value | 40%-50% |

| Ash content | less than 0.3% |

| Moisture Content | less than 3% |

| TI Content | 14-24% |

| QI Content | 3-8% |

| Beta resin | more than18% |

| Volatile Matter | less than 56% |

Normally using for Carbon factory. Graphite/Graphite electrod factory

1.Application:Coal tar pitch used to produce coke (ash content less than 0,25-0,50%) and pitch-binder used in the production of anode mass in the production of aluminum, electrodes and electrode rods, graphitized products, coalgraphitic blocks, etc.; for manufacturing briquetted coal fuel, rolled roofing, pitch plastic and paint for pipes corrosion protection, tanks, metal constructions, etc. middle temperature coal-tar pitch as binder is modified by p-tert benzaldehyde

2.Product name:Modified pitch,Coal tar pitch, Medium temperature pitch ,High temperature pitch

Softening point :80-90, 105-115, 120-130, more than 130 etc.

Coal Tar Distillates

Coal tar distillates are obtained by fractional distillation of coal tar procured as by-product from steel plants. Many by-products of coal tar are obtained at different temperature.

COAL TAR PITCH:

COAL TAR PITCH - MEDIUM & HIGH SOFTENING POINT GRADES already approved for Clay Target Manufacturing, Activated Carbon Manufacturing, Pavement Seals, Roofing Applications, Road Coating Applications, Carbon Brush Manufacturing, Water Proofing etc.

IMPREGNATING PITCH for Impregnating of graphite electrode & refractory bricks

BINDER PITCH for all binding application

Any questions, please contact Judy for quick feedback

MOBILE/WHATSAPP/WECHAT:+86 130 8215 9569