Гидравлический складально-мерильная машина

- Категории: Sheet Folding Machine >>>

- Поставщик: Nantong,Wenao,Import,And,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

folding machine for sheet plate manual|folding machine for sheet plate manual|folding machine for sheet plate manual |folding machine for sheet plate manual

Function and characteristic:

Name | Data | Unit | Remarks | |

Max. bending thickness | 3 | mm |

| |

Max. bending width | 1320 | mm |

| |

Bending angel | 120° |

|

| |

Max. distance between pressing beam and working table | 110 | mm |

| |

Main motor | Model | Y112M-4 |

| |

Power | 4 | kW |

| |

Oil pump | Model | PVL1-28 |

|

|

Volume | 28 | L/r |

| |

Pressure | 21 | Mpa |

| |

Size | Length | 2200 | mm |

|

Width | 1200 | mm |

| |

Height | 1800 | mm |

| |

Wight | 1800 | kgs |

| |

Function and Characteristic:

1.The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured.

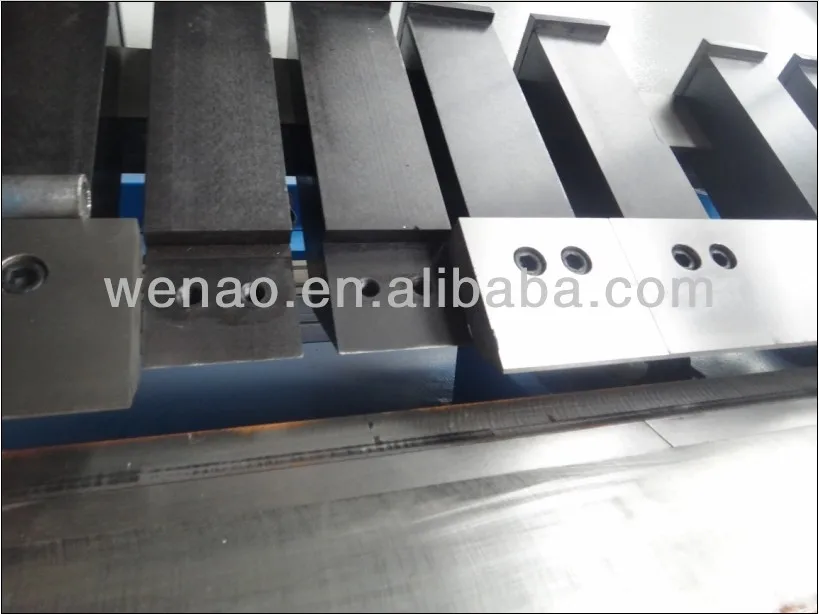

2.Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use.Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces.

3.The bending angle and back gauge is controlled by numerical control system, rapidly and accurately.

Main components:

-SIKO digital display device

--Integrated hydraulic system-OMEGA-USA

-- Axial plunger pump-SHANGHAI

-- HENGLI main motor

--Japan VALQUA seals-JAPAN

-- SIEMENS main electric parts-GERMAN

Purpose and application range of the machine tool

The machine tool adopts welded steel plate construction. Eliminate internal stress by heat treatment, assuring high strength, good rigidity, small deformation, easy operation and high endurance.

The machine with hydraulic driving system can run stably and repair easily. The upper die is sectional type that can combine to 0the different length willfully, suitable for the plate and case part’s manufacture. The working angle can be adjusted rapidly.

The machine is widely used by manufacturers for forming electrical and electronic switch boxes, which is also used in cooking utensil, furniture, all kinds of work-pieces, decorative industry and all shops of other industries

WC62Y Series Techinical data:

| Model | Max. bending thickness(mm) | Max. bending width(mm) | Bending angel(degree) | Max. distance between pressing beam and working table(mm) | Main motor(kw) | Weight(kg) | Size (mm) |

| 3*1320 | 3 | 1320 | 0-120 | 100 | 4 | 2000 | 2270*1200*1800 |

| 3*2000 | 3 | 2000 | 0-120 | 100 | 4 | 3000 | 2880*1500*1800 |

| 3*2500 | 3 | 2500 | 0-120 | 100 | 4 | 3400 | 3380*1500*1700 |

| 3*3200 | 3 | 3200 | 0-120 | 100 | 5.5 | 3900 | 4100*1500*1800 |

| 4*1320 | 4 | 1320 | 0-120 | 100 | 4 | 2200 | 2270*1200*1800 |

| 4*2000 | 4 | 2000 | 0-120 | 100 | 4 | 3100 | 2880*1500*1800 |

| 4*2500 | 4 | 2500 | 0-120 | 100 | 4 | 3600 | 3380*1500*1700 |

| 4*3200 | 4 | 3200 | 0-120 | 100 | 5.5 | 4100 | 4100*1500*1800 |

| 5*2000 | 5 | 2000 | 0-120 | 100 | 5.5 | 3400 | 2880*1500*1800 |

Accessory:

-Front extensive arm, 5 pieces

--Anchor bolt, 4 pieces

--Nut, some pieces

--Washer, some pieces

--Oil gun, 1 piece, Foot pedal

After sales service

1.Our company is committed to develop new products, improve the quality;

2.We supply the service of OEM/ODM.

3.Perfect after-sales service network throughout the world to convenient our customer;

4.24 hours online service;

5.Free training supply;

Product Description

hydraulic steel stainless sheet metal bending machine sheet bender folding machine folder pan brake machinery

Standard Features

1. Hydraulic clamp and unclamp from foot switch, this allows one man to operate machine and hold material in both hands; Clamping is limited to 10mm increments for safety. Unclamp from foot switch.

2. Rapid head adjustment allows easy change different size material, by moving the handles, Adjustable to suit special jobs .

3. Fingers clamp blade are high carbon steel, Apron blade high tensile steel.

4. Electrics low 24 volts foot switch. Overload protected.

5. Clamping provided by large rams, Oil delivered to rams through steel pipes this is to minimize expansion of hydraulic hose when working at full capacity.

6. Unclamp is controlled, to allow the operator to regulate the open height

7. Bed head and apron are unique design, to provide maximum strength. To give a straight fold.

8. Automatic and manual control. In auto cycle after clamping start auto a[rpm will come up to angle set, then apron will go down and the head will unclamp to amount set by operator.

9. Electric components is.SIEMENS

Specifications

Monolithic steel-welded construction

Hydraulic system drive,

CNC system,high precision

Easy to operate

Function and characteristic:

The machine tool is full welded-steel plate construction. After vibration aging treatment, the deformation is minor so that the accuracy can be ensured.

Machine is hydraulically powered. It is low energy construction, easy to maintenance and durable in use.

Upper acting die is sub-portfolio with the open height up to 110mm and suitable for producing disk, box like workpieces.

The bending angle and back gauge is controlled by numerical control system, rapidly and accurately

Using a combination of blowing and automatic folding kinfe technology. Adopting large-screen liquid crystal display intelligent control system.The use of teo-wheeled two-speed system,regardless of the size of the comptroller line setting a precise folding. The running speed adjustment range,can be matched with a variety of ironing machine.With self-diagnostic function,single-link signal detectiontechniques and improve the safety protection system.The control computer by realy output port without intermediate realy accurate and easy maintenance.With automatic elimination of static switching devices and safety protection.

Purpose:

This machine can be used to shape metal sheets into boxes and pans in various sizes.

Also used for ventilation, cases, trays, kitchen, furniture.

Functions and Characteristics:

This type hand folding machine can be used to make electric box. Also, it is widely used in the production of conveying machine, tote box, varies kinds of box and disc. It is popular both in and aboard wit the features of ligt, energy saving, high efficiency, widely usage, etc.

Features:

1. Heavy duty steel fabricated frame provides accurate bends

2. Extended fingers allows bending of pans or boxes to a depth of 200mm

3. Machine equipped with a graduation ruler on both sides, readout eliminates the bend angle guess work

4. Ground segmented fingers can be repositioned to suit many applications

5. Safety top beam support stop lever located on right side of machine

6. Quick action beam adjustment for varying material thickness

7. Includes rear manual back gauge