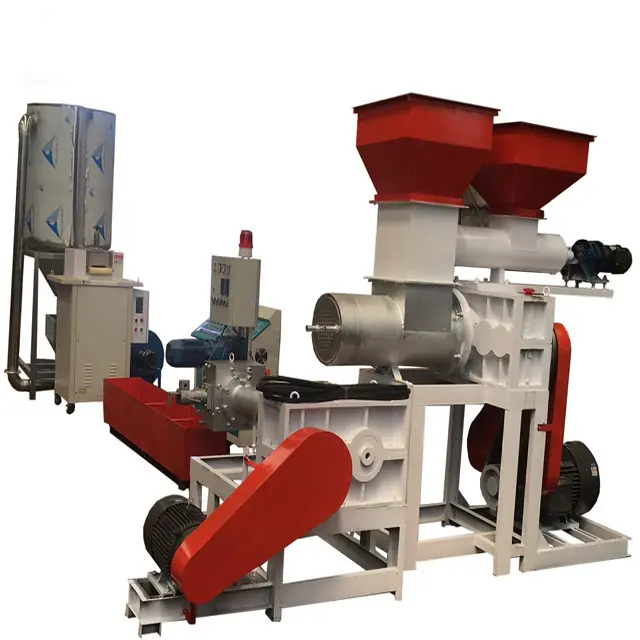

CGB-400-3 гравиметрический blenderautomatic полиэтиленовые гранулы блендер порошок с смешивания дозатор системы

- Категории: >>>

- Поставщик: Wuxi,Longterm,Machinery,Technologies,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Overview

PRODUCT SPECIFICATIONS

Installation method | Platform installation type (not including platform production) | ||||||||

Measurement method | Weighing type measurement | ||||||||

No. of measuring components | 3 components (3 sets of air valves for unloading) | ||||||||

Mixing amount | 50kg/hr | ||||||||

Weighing ratio accuracy | Within 5‰ | ||||||||

Proportion of excipients | Main material: 50%, auxiliary material 30%, auxiliary material 20%, | ||||||||

Applications | Granular low-temperature plastic with diameter of 3-4mm | ||||||||

Material | All parts in contact with materials are made of stainless steel | ||||||||

Stirring motor power | 0.12kW | ||||||||

Configuration of the main components of the machine | |||||||||

Controller | Siemens PLC | ||||||||

Display screen | German Siemens SMART700\\Domestic FLEXEM | ||||||||

Level switch | German IFM | ||||||||

Weighing sensor | America CELTRON | ||||||||

Safety switch | German SCHMERSRC | ||||||||

Relay | Japan Izumi | ||||||||

Cylinder | Tanwan AIRTAC | ||||||||

Solenoid valve | German | ||||||||

Others | 1.With recipe storage function, up to 100 groups of recipes can be stored. | ||||||||

2.Hierarchical security password control and alarm history record function. | |||||||||

3.With sound and light alarm. | |||||||||

4.The parts in contact with the raw materials are made of stainless steel. | |||||||||

5.Modular and detachable structure design, save space and facilitate cleaning. | |||||||||

6.Appearance color of equipment (three standard colors). | |||||||||

7.Power supply voltage: single-phase 230V 50Hz | |||||||||

PRODUCT CONFIGURATION

Siemens SMART700

Sensor

Sensor

Muti-station-Hopper-Loader Technical Parameter | ||

Name | Specification | |

Type | CAL-10HP-G4 | |

Operational capability (kg/hr) | 700KG/HR (Distance: 20M) | |

Hopper | 4pcs | |

Total power(KW) | 7.5 | |

Material | Stainless steel | |

Voltage specification | 3φ400V 50HZ | |

Shape size H*W*D(mm),Not included base | 1780*760*760 | |

Machine configuration | Air Blower: China MeiQiLe | |

Contactor: France Schneider | ||

Electrical appliances:France Schneider | ||

Application

For the extruding online processes with multi, proportional and high precise of materials like pellets, sheets, regrinds or powder in plastics industry. Gravimetric dosing and blending unit for direct installation on the inlet flange of a plastics processing machine or on floor stand. The unit can dose and blend up to 4 components by standard and can be tailored for 6 components or more.

Material blending with high accuracy and repeatability, specifically designed for injection moulding/blow moulding machines and extruders with an throughput from 50kg/h to 3000kg/hr. Actual metered and weighed amounts are constantly checked against the pre-selected set values by a modern PLC based control. This guarantees an exceptionally high recipe accuracy (±0.1~±0.3%) by continuous self-optimization.

SALES AND SERVICE NETWORK

Export Plywood Package

Wuxi Longterm Machinery Technologies Co.,Ltd.

Our company is a collection of scientific research and development and production of wire and cable

equipment and a variety of efficient energy-saving extrusion production line of key enterprises, so far, the main product including wire and cable Insulation and Sheathing production Line, TQD series Pneumatic Type belt Haul off, LF series Portal Type Pay-off, LSP series Portal Type Take-up, Various Wire Accumulator, Capstan Haul-off, Pay-off & Take-up, Cooling Water Trough, and Optical Fiber Equipment, Communication Cable Equipment, Signal Cable Equipment, Gravimetric Blender, MB feeder, accumlator, metercounter ect...

equipment and a variety of efficient energy-saving extrusion production line of key enterprises, so far, the main product including wire and cable Insulation and Sheathing production Line, TQD series Pneumatic Type belt Haul off, LF series Portal Type Pay-off, LSP series Portal Type Take-up, Various Wire Accumulator, Capstan Haul-off, Pay-off & Take-up, Cooling Water Trough, and Optical Fiber Equipment, Communication Cable Equipment, Signal Cable Equipment, Gravimetric Blender, MB feeder, accumlator, metercounter ect...

Our company has a technical administration team who engages wire and cable equipment industrial more than twenty years, as well as experienced engineer and skilled workers, our honest business reputation and good sales achievement, win the trust from our domestic and overseas customers, the products are exported to United States, France, Spain, Portugal, New Zealand, Brazil, Mexico,Chile, South Africa, Zambia, Egypt, South Korea, Singapore, Indonesia, Thailand, etc...

FAQ

− Q: What can we offer our customers?

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company?

A: We have more than 10 years of professional experience in the production of cable machinery, providing high-quality,

high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company?

A: We have more than 10 years of professional experience in the production of cable machinery, providing high-quality,

high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.