Высококачественное итальянское прядильное кольцо 36x47x8x1 для

- Категории: Textile Machine Parts >>>

- Поставщик: PROSINO,SRL

Поделиться:

Описание и отзывы

Характеристики

Details Images

Products Description

STEELHAWK: the best ring you could ask for

STEELHAWK represent the state-of-the-art spinning ring, based on 70 years + years of collaborationship between PROSINO and the most demanding OEM’s and spinning mills worldwide.

High working speed can be reached with STEELHAWK spinning ring thanks to the following factors:

- Low roughness (less than 0,2uRA).

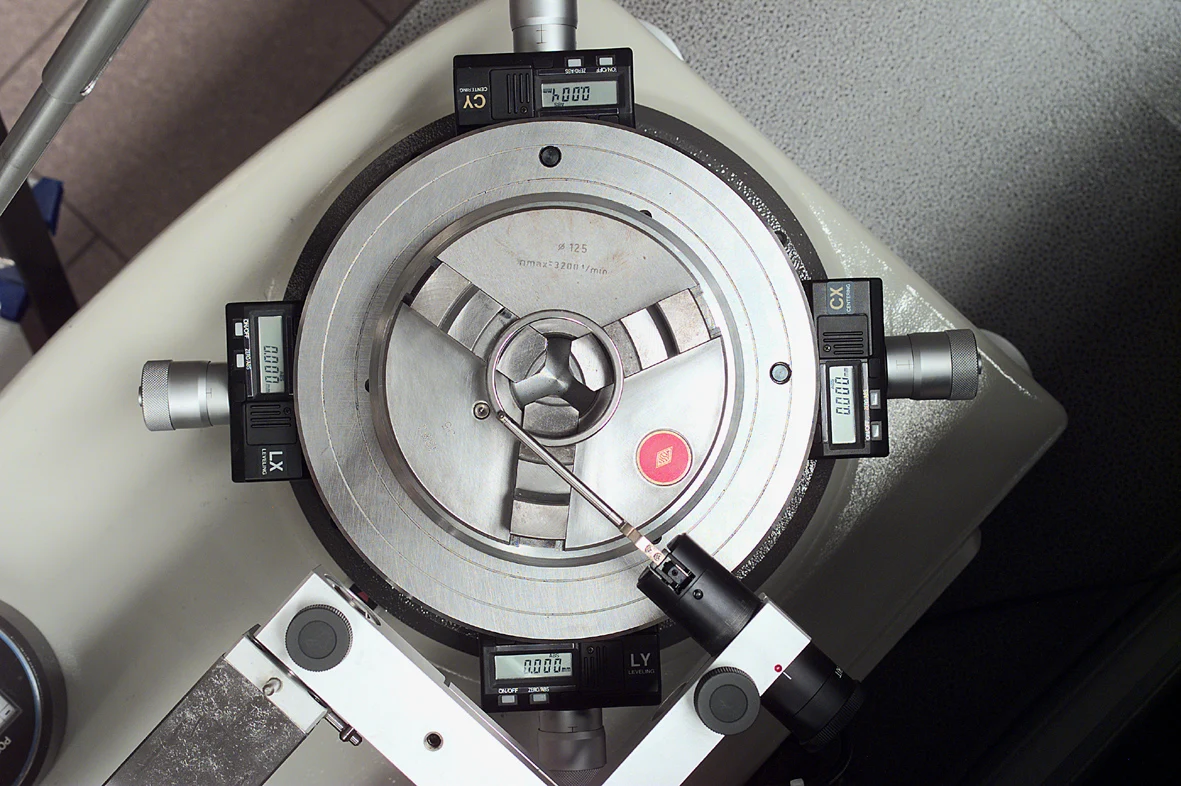

- Ultra precise flange profile achieved thanks to the unique PROSINO form turning technology.

- Dry lubrication anti-wear

- Plasma-like coating

- Plasma-like coating

- Very high consistency of all mechanical parameters (out-of-roundeness, hardness, roughness)

Certifications

Our Advantages

NO RUNNING IN | Traditional spinning rings require the so called “break-in” procedure that creates a steel tribo-oxidation. The STEELHAWK spinning ring has a special non-metallic dry lubrication coating that allows you to start the new ring at full speed without any long and un-productive running in schedule. |

NO NEED OF SPECIAL TRAVELLERS | STEELHAWK rings do not require special travellers and superior performance is achieved using international traveller manufacturing brands. Customized flange profile can be supplied upon request. |

HIGH WEAR RESISTANCE PLASMA-LIKE COATING | Long time experience, field trials, continous customer feed-back have given a fundamental contribution to the definition of the best coating to be applied on STEELHAWK spinning ring. This coating has an excellent resistance even in the most harsh working environment (compact cotton spinning, dyed synthetics, 100% rayon). |

QUALITY CONTROL AT ALL STAGES | Total Quality is the basic of the company’s operations and committed long term objective to achieve every manufacturing process. High quality standards and consistent controls in each production phase permit the manufacture of reliable products with zero ratio defectiveness. |

RAW MATERIAL | The raw material used by PROSINO is 100% European outstanding low sulfur, high purity steel that undergo the most challenging inspection before been released as “OK for production”. |

Why Choose Us

OUR ADVANTAGES, YOUR BENEFITS

When it comes to spinning and twisting rings, PROSINO S.r.l. is the market leader with an yearly manufacturing of more than 9.000.000 rings and world market presence since 1946. Maximum focus on the product, technical skills, great experience, fully automated manufacturing, OEM’s* partnership, consistency in quality, maximum care in before and after sales, PROSINO S.r.l. is the right partner of the best spinning mills worldwide.

That’s why we are pride to say that WE KEEP THE WORLD SPINNING!

Company Profile

WHERE WE COME FROM

Prosino S.r.l. established in 1946 began flourishing in the Italian Textile area of Biella producing spinning and twisting rings, commencing exports into other European markets and later to USA. During 1995, Prosino with traditional textile machinery infrastructure diversified and commenced the manufacture of turned and heat treated Rings for high precision Ball & Roller Bearings.

Today Prosino’s manufacturing Ring program extends to Hydraulic motors, Aerospace, Industrial valves and many other specialised mechanical engineered Industries. The company has a strong foundation with the proud third generation Prosino family management, successfully updating new programs by adapting the original textile sector with a new range of products to meet this continuous evolving business. Over years of expertise Prosino has developed a new client base who appreciate reliability, flexibility and innovation. And since the 80’s has established strong commercial links with the leading Swiss company RIETER AG, also involved in Textile spinning machinery bringing together other associated companies from this group.

Today Prosino’s manufacturing Ring program extends to Hydraulic motors, Aerospace, Industrial valves and many other specialised mechanical engineered Industries. The company has a strong foundation with the proud third generation Prosino family management, successfully updating new programs by adapting the original textile sector with a new range of products to meet this continuous evolving business. Over years of expertise Prosino has developed a new client base who appreciate reliability, flexibility and innovation. And since the 80’s has established strong commercial links with the leading Swiss company RIETER AG, also involved in Textile spinning machinery bringing together other associated companies from this group.

FAQ

- WHAT IS THE LIFETIME OF STEELHAWK RINGS?

When, due to wear and tear over time, the geometry of the flange is altered and the surface has lost its initial characteristics (e.g. level of roughness), the coefficient of friction between ring and traveller starts to change (especially between ring and ring). The tension differences that are generated require an increase in weight of the traveller with increased possibility of breakage and less control over the spinning process.

We should remember that temperatures of over 800° C can be reached at the point of contact between ring and traveller. One of the main effects of this thermal stress is a longer or shorter life span. Using mathematical calculations and practical observation we have noted that there is a strong correlation between the life span of travellers (in days) and the life span of rings (in months/years). The rotation speed of the spindles, the quality of lubrication of the threaded fibre, the length of the small tube and the general conditions of the spinning machine have an effect on the life span of the travellers. The main reason for that is that the high temperatures developed by friction causes micro-welds between the ring and the traveller, which in the long term lead to a degeneration in the surface of the ring.

This phenomenon can be easily observed in traditional rings, which do not have protective coatings against wear and tear. Thanks to their special coating, the STEELHAWK rings made by PROSINO BORGOSESIA RINGS do not allow micro-welds to occur on the travellers and manage to keep their surface in the same perfect conditions for a much longer time, and consequently they wear out much more slowly.

We strongly advise against using traditional spinning rings and suggest that you use STEELHAWK rings. In short, the choice of STEELHAWK, in the right conditions of use, allows you to double the average life cycle of a ring.

This phenomenon can be easily observed in traditional rings, which do not have protective coatings against wear and tear. Thanks to their special coating, the STEELHAWK rings made by PROSINO BORGOSESIA RINGS do not allow micro-welds to occur on the travellers and manage to keep their surface in the same perfect conditions for a much longer time, and consequently they wear out much more slowly.

We strongly advise against using traditional spinning rings and suggest that you use STEELHAWK rings. In short, the choice of STEELHAWK, in the right conditions of use, allows you to double the average life cycle of a ring.

- MAY I USE ANY KIND OF TRAVELLERS ON YOUR RINGS OR I HAVE TO USE A SPECIFIC BRAND ?

On our spinning rings do not require special travellers. Anyhow superior performances is achieved using international traveller manufacturing brands.

- IS THERE A PRICE DIFFERENCE BETWEEN FLANGE 1 AND FLANGE 2 ? WHEN I HAVE TO SELECT FLANGE 1 OR FLANGE 2

No. We can supply any flange without extra cost. The selection between Flange 1 and flange 2 must be done on practical experience.

Generally speaking coarser counts than NE 20 are spun with Flange 2. The use of Flange 2 is also suggested in core-yarn spinning.

Generally speaking coarser counts than NE 20 are spun with Flange 2. The use of Flange 2 is also suggested in core-yarn spinning.

- WHAT IS THE MINIMUM RING DIAMETER THAT YOU CAN PRODUCE ?

We produce rings with a minimum diameter of 32 mm for super fine counts. With ID less than 36 mm FL 1/2 is also suggested.

- WHICH TYPES OF FLANGES DO YOU OFFER ?

We can produce any flanges that the customer wants. The most popular ones are NORMAL flange and ANTI-WEDGE (Asymmetrical) flange.

Flange 1/2 for fine and super fine counts are also available.