Фабрика поставщик AAC бесзольная пескоструйная линия производства легкая пена настенная панель машина для кирпича

- Категории: >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Factory Supplier AAC Fly Ash Sand Block Production Line Light Weight Foam ALC Wall Panel AAC Brick Making Machine for Building

Hongfa Machinery since 1990

A leader developer& Manufacturer of Construction Material Machinery.

Guangxi production base: 9 machinery factories

Updated to state-owned enterprise.

Raw material

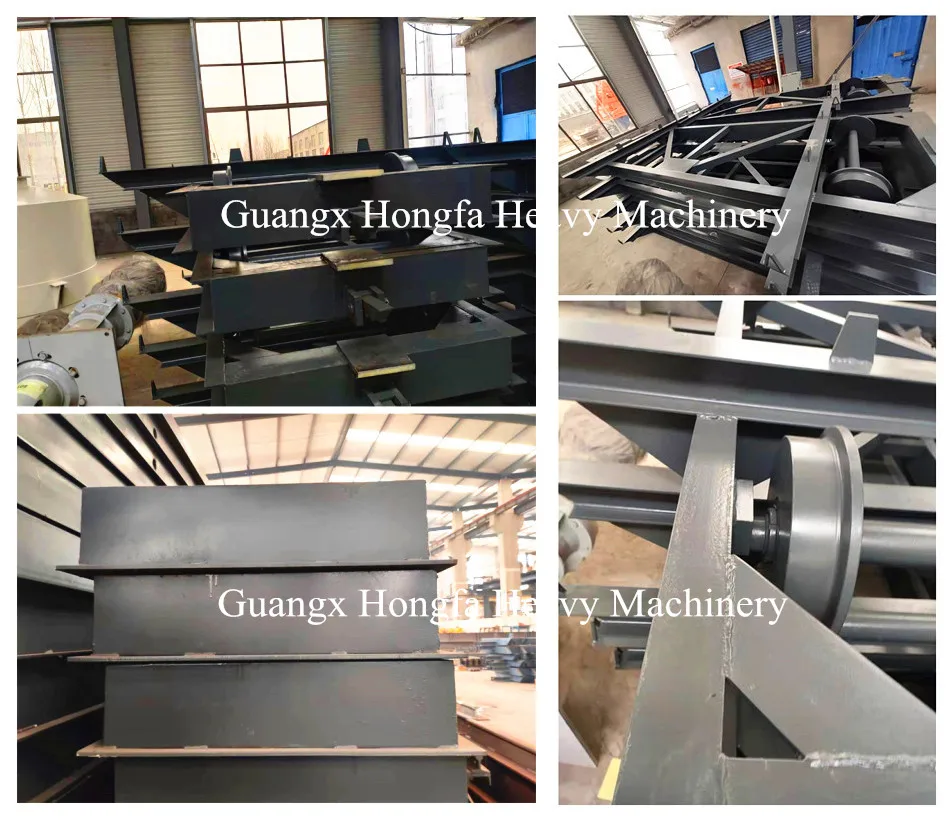

To make our AAC block production line reliable and durable, HONGFA FACTORY purchases steel from famous steel manufacturers in

China. We only use steel plates that have not been rolled. A few underwater plasma cutting machines were purchased to guarantee

the high precision of our autoclaved aerated concrete production machines.

Welding workshop of Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line

Welding robots were used to improve the productivity and welding performance.

Thus we can get consistent AAC production equipment.

High technology for AAC:

1.light weight .Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay block and 1/5 common concrete.So use the Light block can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2.keeping temperature .It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line/GAS block machine / Fully automatic AAC block production line/aerated autoclave concrete block

machine/AAC machine /AAC line / Aerated Autoclave Concrete Block Machine AAC Panel AAC Bricks Gas Block Manufacturing Plant Automatic AAC Production Line/ AAC Brick Machinery / Alc block machine/AAC block machine price

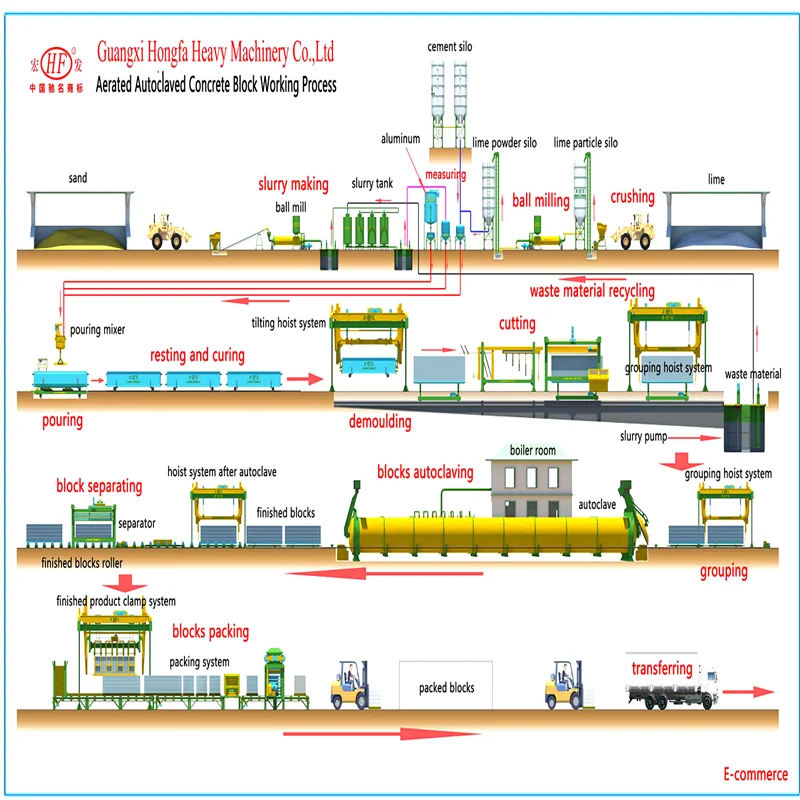

Main process flow of Made-in-China AAC brick making machine production line concrete block plant aac block manufacturing plant cost/AAC Block Machine, AAC Block Machine Price, AAC Block Production Line

Hongfa is a complete solution supplier and a complete set of equipment production

supplier. /aac block price philippines AAC block plant production line /AAC line /AAC machine

1.Raw material preparation for AAC plant:

A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

2. Dry and wet Ball mill for lime and sand

3.Slurry batching: The prepared and stored raw materials to be used are metered, adjusted for temperature and concentration, and a small amount of dosing materials are metered on site, and then fed to the stirring equipment in turn according to the process requirements.

4. Pouring: In this process, the materials that are put into the mixer after the previous batching

process are measured and adjusted if necessary, and the materials that meet the time,

temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it

constitutes the core link of aerated production as the batching process.

Pouring system: Measure various raw materials according to

the proportion, and pour them into the mold after stirring. The control system adopts integrated PLC control system

5. Cutting of hongfa aac block production line : As the main equipment in the production

process of aerated concrete block, the quality and cutting accuracy of aerated block cutting machine directly affect the quality of AAC block. JQF series of air filling block cutting machine of our company has the characteristics of high efficiency and high degree of automation .

Aerated Autoclaved Concrete Block Making Machine,Aac Block Production Line,

AAC Block /ALC Panel Cutting Machine

1) Highly intelligent operation and management, PLC centralized control, with frequency converter to realize the whole cutting process automatic operation.

2) Hongfa cutting machine can not only produce AAC blocks, but also produce ALC panel, and cut the blocks and panels in six sides, so the quality of products is not affected by mould oil and mould deformation.

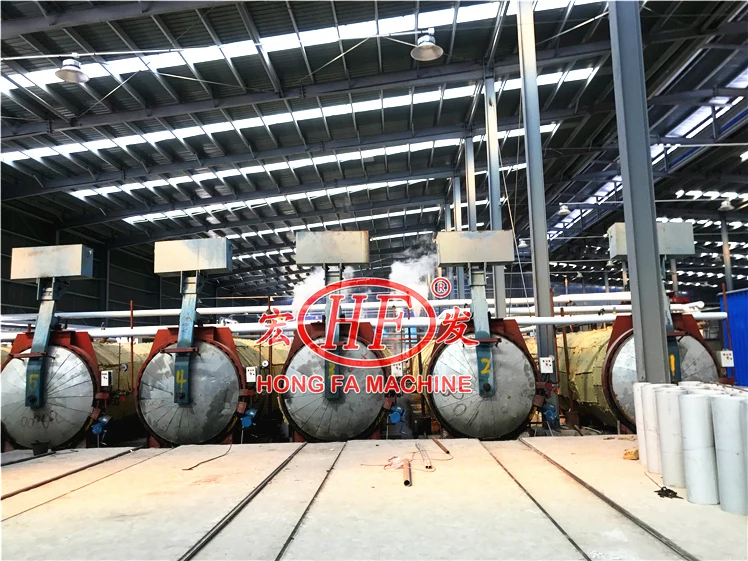

6. Autoclave curing for AAC block production line /aac panel block making machine price philippines/ autoclave for aac blocks /Gas block production line /Fly ash AAC block production line / Full automatic AAC block production line

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line is running in our factory! Welcome to visit us !

Hongfa AAC block making machine AAC block machine plant/AAC Block manufacturers /AAC Block Plant/AAC block production line /AAC brick machinery / AAC block plant/AAC equipment /AAC block machine /Factory Supplier AAC Fly Ash Sand Block Production Line Light Weight Foam AlLC Wall Panel AAC Brick Making Machine for Building

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line , welcome to visit our factory to see the production line running!

Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC

Block manufacturers AAC Block Production Line Introduction:

QC Dept. will test our AAC block machine at least three times before shipping.

Shipping Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line /AAC Block Machine, AAC Block Machine Price, AAC Block Production Line /ALC panel production line / ALC block machine / Automatic AAC production line AAC block machine

Some of successful plants for Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line/AAC machine /Gas block production line /AAC line

Advantages of the AAC block application

1. Sound proof

AAC wall has an excellent sound Transmission class (STC) ,rating of 44. Result: Virtually Soundproof Interiors

2. Thermal Insulation

It has highest thermal rating in the industry….R30! Thus provides well insulated interiors, keeping out warm air in summer and cold air in winters. AAC reduces Air conditioning cost by 30%.

3. Earthquake Resistant

Earthquake forces on structure are proportional to the weight of the building, hence AAC shows excellent resistant to earthquake forces. Regions of high seismic activity like Japan exclusively use AAC. It has been proven to withstand wind loads of category 5 tropical storms.

4. Floor Space Area

Use of thinner blocks (6" instead of 9" exterior walls) because of its excellent water barrier & insulation properties leads to an increase in floor space area between 3-5%.

5. Cost saving

Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost saving. Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving up to 66%.

6. Fire Resistant

Best in class fire rating of 4 hours. The melting point of AAC is over 1600 ºc, more than twice the typical temperature in a building fire of 650 ºc.

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Wall Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line,

Organic fertilizer equipment, hydroelectric power plant, Portland Cement Plant, Quicklime kiln equipment, Concrete Pipe Machine, Concrete Tile Machine, Mining Machinery, Concrete Batching plant, etc

Hongfa Strengths

More than 33 years experience. 1500 employee (50+engineers)

2) Total 9 factories with 600,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Contact Information:

Foreign Trade Dept. : Emily Lee

Guangxi Hongfa Heavy Machinery Co., Ltd.

What's app:+86 15177094840

Wesite: www.gxhongfa.cn

Welcome to send me any inquiry of Hongfa Germany Ytong Autoclaved Aerated Concrete AAC block machine Plant AAC Block manufacturers AAC Block Production Line !