Вставки из карбида CNMG вставки цементированного

- Категории: Turning Tool >>>

- Поставщик: Zhuzhou,Apple,Carbide,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

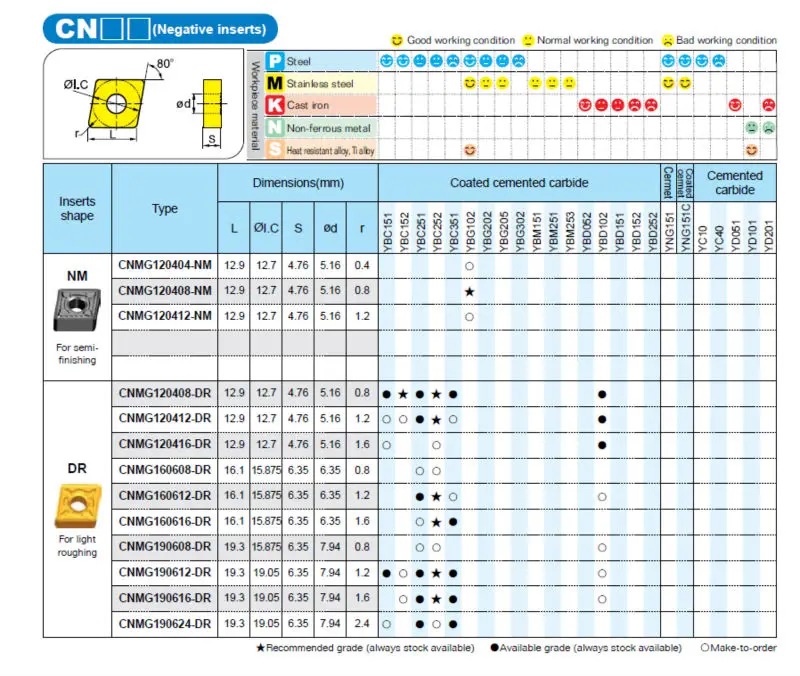

Inserts carbide CNMG ,cemented carbide inserts,carbide cutting inserts

1, High hardness (8~93HRA, equal 69~81 HRC)

2, Good hot hardness (can reach 900~1000°C, keep 60HRC)

3, Excellent wear resistance

4, Increase the cutting speed

5, Improve production efficiency

6, Shorten the production cyle.

Recommended cutting parameters:

| Workpiece material | Range of machining | Grade | Recommended cutting speed(m/min) | |

| P | Steel | For finishing | YBC151 | 180-460 |

| YBC152 | 220-500 | |||

| For semi-finishing | YBC251 | 160-440 | ||

| YBC252 | 180-480 | |||

| For roughing | YBC351 | 130-380 | ||

| M | Stainless steel | For finishing For semi-finishing For roughing | YBM151 YBM251 YBM253 | 110-280 |

| K | Cast iron | For finishing | YBD052 | 200-500 |

| YBD102 | 200-480 | |||

| For semi-finishing | YBD151 | 180-450 | ||

| YBD152 | 190-450 | |||

| For roughing | YBD252 | 150-380 | ||

Grade list of tungsten carbide turning inserts:

| YBC151 | High wear resistance of the matrix and MT-TiCN, thick Al2O3 and TiN coating. |

| YBC152 | Thick TiCN and Al2O3 coating |

| YBC251 | tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

| YBC252 | Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

| YBC351 | Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating. |

| YBG102 | nc-TiAN coating and fine-grained matrix. |

| YBG202 | nc-TiAN coating and fine-grained matrix. |

| YBG205 | Added abrasion resistance and high temperature rare elements ultrafine TiAlN based nano-coating. High layer hardness and excellent resistance to high temperature provide effective protection for the cutting edge. |

| YBG302 | nc-TiAN coating and flexible cemented carbide matrix. |

| YBM151 | Special organizational structure and TiCN, thin Al2O3 and TiN coating. |

| YBM251 | Good toughness and strength matrix and TiCN, thin Al2O3 and TiN coating. |

| YBM253 | With the advance extra fine grain nanometer coating technology, match up with the high toughness gradient matrix. |

| YBD052 | CVD coating(extra thick Al2O3 & thick TiCN), hard matrix. |

| YBD102 | CVD coating (thick Al2O3 & thick TiCN) , hard matrix. |

| YBD152 | CVD coating (thick Al2O3 & thick TiCN), hard matrix, it is anti-stripping. |

| YBD252 | CVD coating (middle thick Al2O3 & thick TiCN), hard matrix. |

| YNG151 | Uniform particle refining organizational ceramal alloy, homogenizing organizational & ring form phase structure, Strengthen bond phase,grain boundary composition design. |

| YNG151C | Physics weather deposit (PVD) coating, high toughness ceramal matrix. |

| YD101 | Fine particle hardness phase WC and bond phase Co. |

| YD201 | Middle particle hardness phase WC and bond phase Co. |

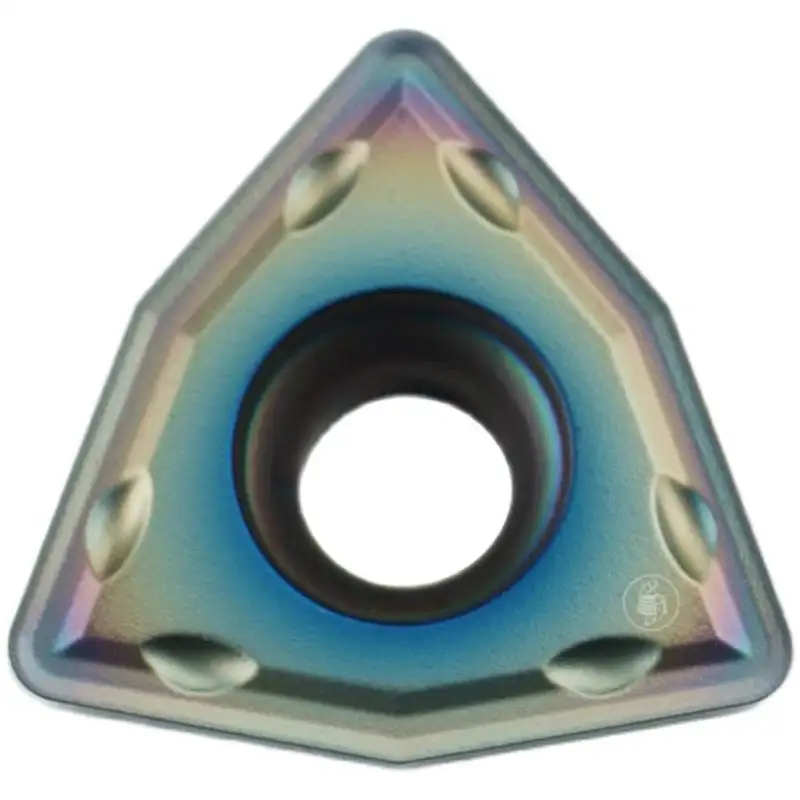

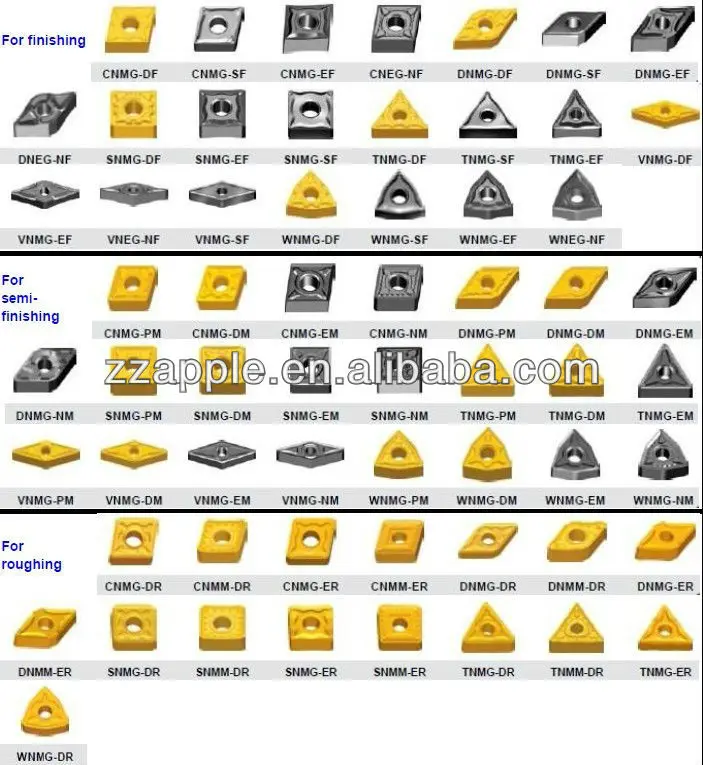

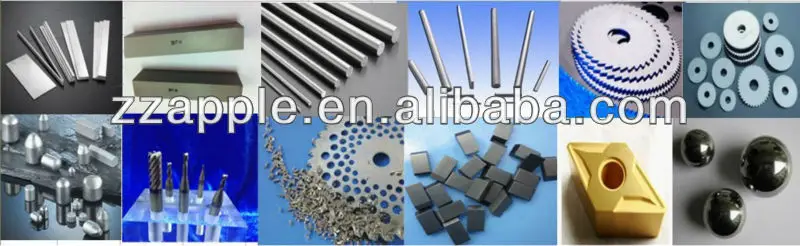

Products show : Tungsten carbide turning inserts

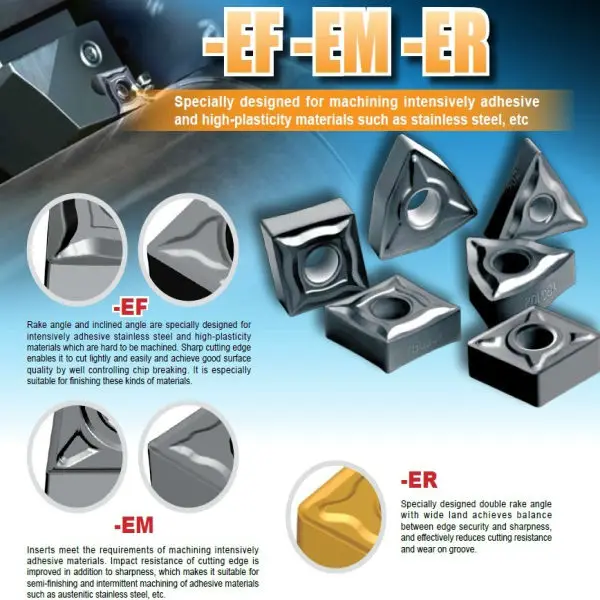

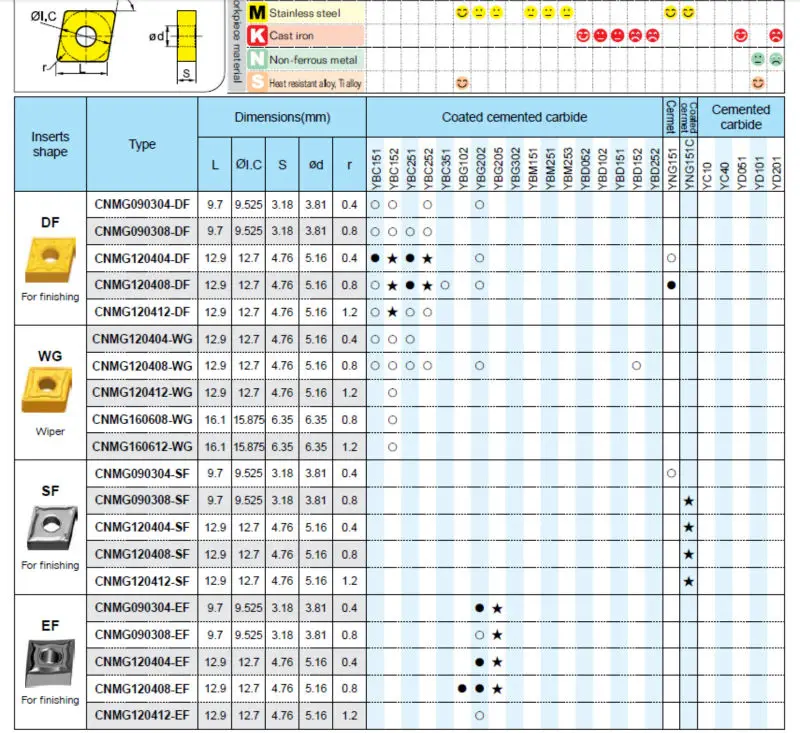

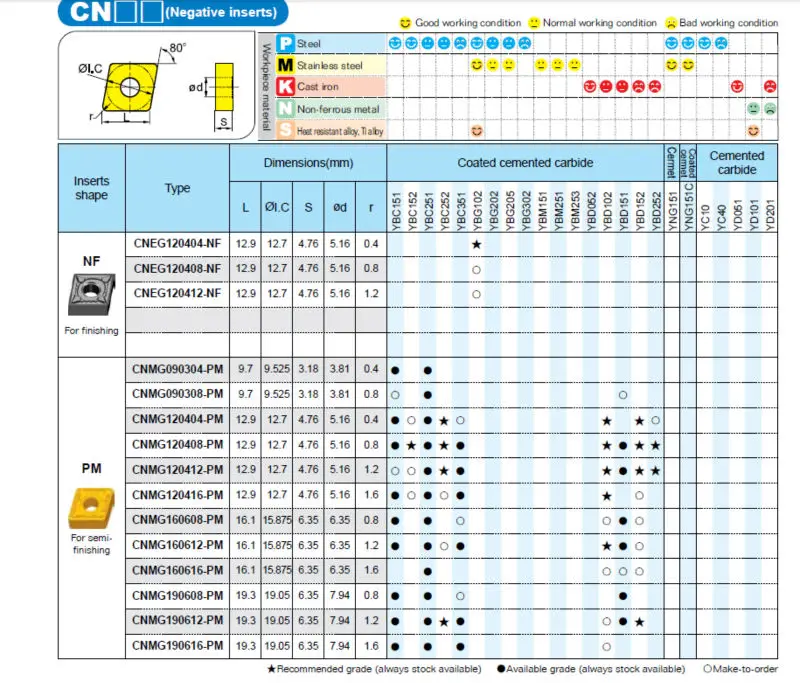

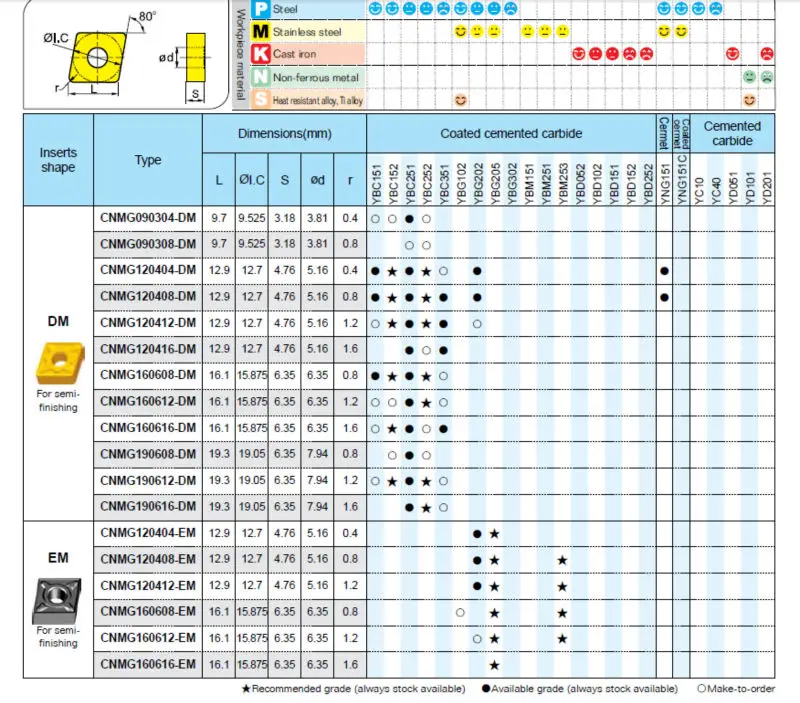

Chipbreaker of carbide turning insert:

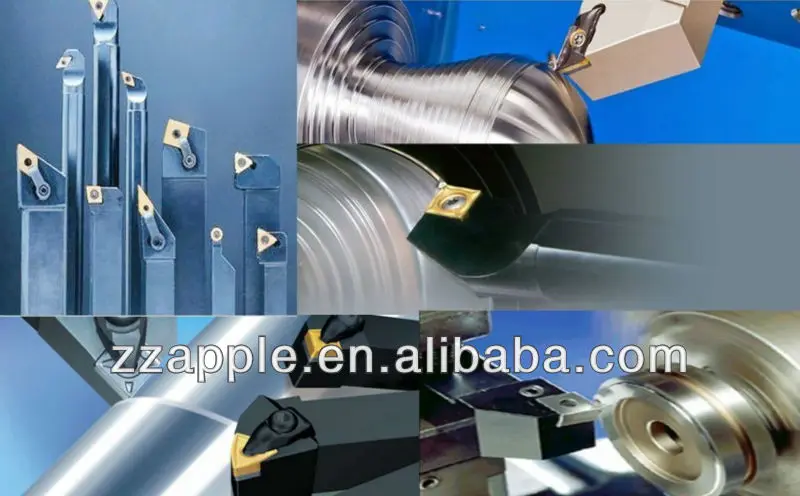

Application of tungsten carbide turning inserts:

Suitable for hardened steel , grey cast iron , chill cast iron, stainless steel , powder matellurgy work piece, thermal spray coating work piece and aluminum ,used for finishing or semi-finishing.

Commonly used models: CNMG, DNMX, SNMG, DNMM, SNMM, TNMM, VNMG, TNMG, CCMT, WCMX, DNMG, SNUN, TNGA, WNMG, RNMG etc.

Guide to selecting tungsten carbide inserts

1, Selecting grade according to workpiece material and working condition

2, Shapes and dimensions

- cutting edge length

- thickness

- hole diameter

- nose radius

- diameter of inscribed circle

3, Tool holders

4, Insert chipbreaker

Package and shipment of tungsten carbide inserts:

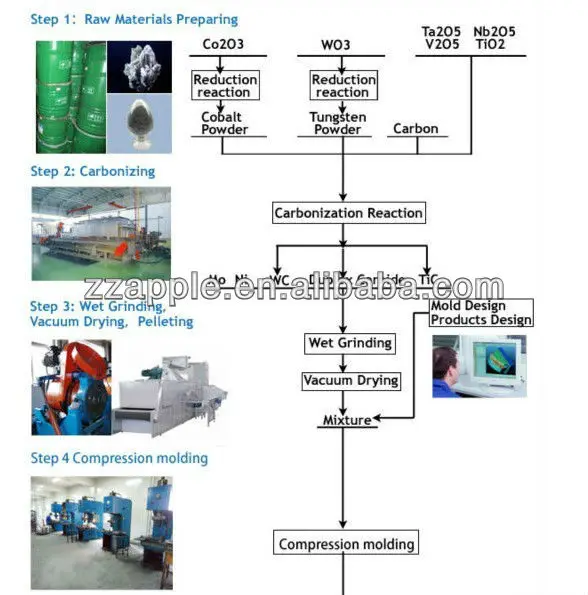

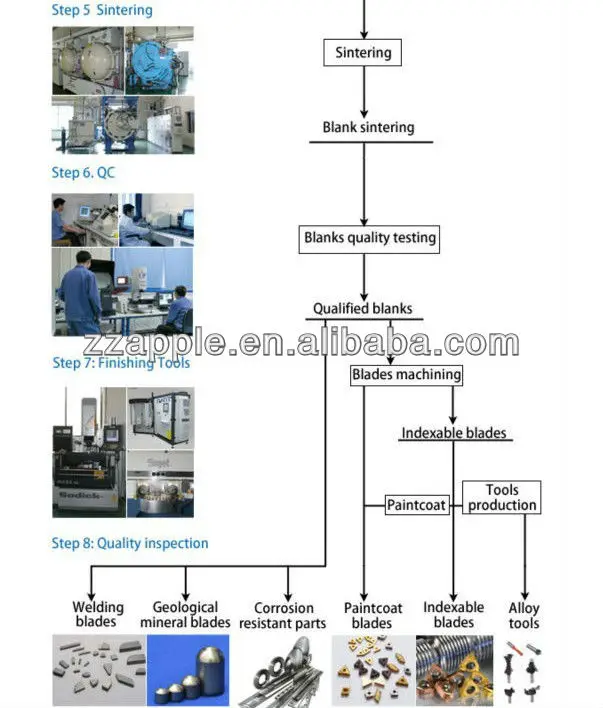

Production flow:

Our quality control:

1. All raw materials are tested in terms of density,hardness and T.R.S before use.

2. Every carbide cnc tool inserts goes through in-process and final inspection.

Our service:

*We can produce products according to your drawings.

*We can provide professional suggestions on products

*We can accept payment terms such as T/T ,Western Union , Paypal and etc.

*We are a professional team and wait for you at any time.

Buyer Notice:

In order to improve our efficiency of communication, kindly inform us the following information while sending us inquiries:

1, Specific sizes or drawings

2, Operation environment

3, Purchase quality of each item

4, Special requirements

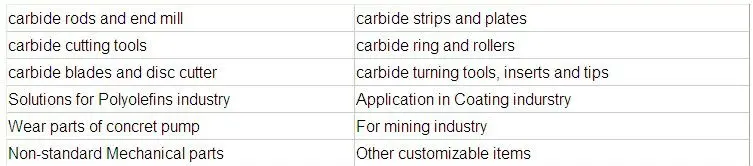

Our product range :

Commonly used models: CNMG, DNMX, SNMG, DNMM, SNMM, TNMM, VNMG, TNMG, CCMT, WCMX, DNMG, SNUN, TNGA, WNMG, RNMG etc.

Please feel free to contact me.