Бумага передачи тепла для пластиковой

- Категории: >>>

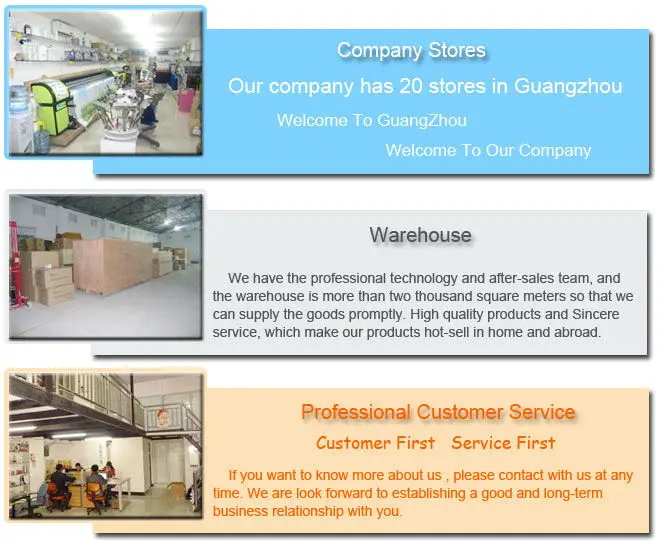

- Поставщик: Guangzhou,Disen,Electromechanical,Equipment,Co.,Ltd

Поделиться:

Описание и отзывы

Характеристики

| Customer First Service First |

heat transfer paper for plastic Using sublimation paper requires two conditions must be : as long as the Micro Piezo print head with a printer can be, for example : E-pson, Roland, Mutoh, Mimaki , etc. in various models and be sure to use sublimation transfer ink , such a dispersion dye ink produced in the transfer temperature will produce dye sublimation and with the substrate . Good quality sublimation ink should not plug the nozzle , vivid colors and good stability.

Sublimation ink transfer paper suitable for use:

|

| Customer First Service First |

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

heat transfer paper for plastic

|

| Customer First Service First |

heat transfer paper for plastic The thermal transfer printing ink with a special pattern of the various special kind of paper is printed on top, and then the temperature and pressure by means of the pattern and then transferred to the product. This particular paper in the transfer process called thermal transfer paper. Transfer printing means the transfer paper to the fabric to dye transfer printing process. It is based on some characteristics of disperse dye sublimation, select 150 ~ 230 ° C sublimation dyes, mixing it with the pulp "color ink" designs according to different requirements, the "color ink" printed on the transfer paper (which is a special paper, so that the transfer paper), and then the printed patterns on transfer paper in close contact with the fabric, the control certain temperature, pressure and time in the case,after diffusion into the fabric inside, so as to achieve the purpose of coloring. Thermal transfer process:

Method: century world is extremely respected and popular products to the gentrification of the dyeing process!

Thermal transfer paper is not the kind of office paper. The thermal transfer printing ink with a special pattern of the various special kind of paper is printed on top, and then the temperature and pressure by means of the pattern and then transferred to the product. This particular paper in the transfer process called thermal transfer paper. Transfer printing means the transfer paper to the fabric to dye transfer printing process. It is based on some characteristics of disperse dye sublimation, select 150 ~ 230 ° C sublimation dyes, mixing it with the pulp "color ink" designs according to different requirements, the "color ink" printed on the transfer paper (which is a special paper, so that the transfer paper), and then the printed patterns on transfer paper in close contact with the fabric, the control certain temperature, pressure and time in the case, after diffusion into the fabric inside, so as to achieve the purpose of coloring. Thermal transfer paper is specially designed for inkjet type printer can be photo-image transfer to light or dark, and other colored fabric. The use of thermal transfer paper specially formulated to hide the fabric color transfer. Can be cut, fade and light film cutting. Fabrics include: T-shirt, banner, pillows, mouse pads, mats and other items.

|

| Customer First Service First |

|