Форма для изготовления бетонной плитки rtv2 силиконовая

- Категории: Резиновые материалы >>>

- Поставщик: Dongguan,Mingcheng,Electronic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

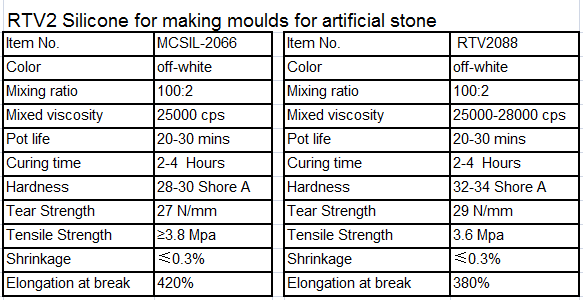

Concrete tiles mold making liquid rtv2 silicone rubber

RTV-2 silicone rubber is generally named as two-part room temperature vulcanized silicone rubber, which features an exceptional fluidity and good operability. When mixed with 2-3% curing agent, they can still be operated within 30 minutes, but will be formed after 4-6 hours. With resistance to deformation, high temperature, acid and alkali, and expansion.

Features of concrete tiles mold making liquid rtv2 silicone rubber :

1. Good flow ability and long working time

2. Medium hardness

3. High tear and tensile strength

4. Easy de-mould from complex replica parts

5. Acid and alkali-resistance

6. Low linear shrinkage

Various apppications of concrete tiles mold making liquid rtv2 silicone rubber:

A: Cultural relic duplication, architectural decoration, statues

B: Resin crafts

C: Lighting ornaments, candles

D: Plaster, Gypsum, Cement, Concrete decorations

F: Model design, product exploitation, etc.

If you need RTV-2 silicone for making gypsum & resin crafts, please click the picture below.

Instructions of How to Make Silicone Rubber Molds for Cultured Stone

1.Build a frame in which to create the mold, using wooden planks. Measure the size of the actual stone that you are using as a model for the cultured stone mold using a measuring tape. Cut the planks to create a box large enough to hold your measured stone with ½ inch of space surrounding the stone on all sides, and with sides 2½ inches higher than the stone. Use wood screws to connect the frame sides and bottom at the joints. Place a strip of masking tape along all joints on the inside of the frame to prevent leakage of the rubber mold-making material.

2.Place the frame onto a flat work surface. Spread a layer of clay inside the frame covering about two inches of the frame bottom, to serve as a bed to stabilize the stone as you create the mold. Spray the clay and all surfaces within the frame with mold release agent. The release agent ensures that the rubber will not stick to the sprayed surfaces.

3.Place the stone into the clay, centered inside the frame. Make sure the side you wish to recreate is facing upwards. Push the stone slightly into the clay, about ¼ inch, and then spray the exposed surfaces of the stone with the release agent.

4.Mix the rubber in a large plastic cup with a craft stick, according to manufacturer directions. Pour the rubber into the frame from a single corner, and fill the frame to the top. Tap the side of the frame as you fill it to release any air bubbles forming throughout the mixture during the pour. Allow the rubber to cure to hardness for the length of time suggested by the manufacturer.

5.Peel the rubber from the stone and out of the frame. All of the stone exposed during the fill should appear in the rubber mold. To make cultured stone, spray the inside of the mold and fill with the concrete of your choice to cure into a stone of the same appearance of the original, with a flat back for easy mounting.

Package of rtv2 silicone rubber for making concrete stone mold:

Part A base silicone: 5kg, 20kg/drum, 25kg/drum or 200kg/drum

Part B CA30 Curing Agent: 250g, 800g/bottle, 1kg/bottle

When the silicone rubber is stored at or below 30 centi degree in the original unopened containers, Silicone Base and Curing agent have a usable life of 10 months from the date of production. After 10 months stockpiles use the Stir to mix the Part A silicone for some minutes, then the silicone can be use again, no influence for other performance.

Why Choose MC Silicone?

1- We have experience in silicone field more than 10 years

2- We have different types of silicone with hardness from 0-60 shore A

3- Catalyst 2%-5% free of charge for tin cure silicone, can be colored as per client request

4- We offer different way of shipping: air, sea, courier.

5- We accept different ways of payment: T/T, L/C, D/P, Paypal, Western Union, Alibaba Trade Assurance Secure payment,etc.

6- We accept different trade terms: FOB,CFR, CIF,etc.

7- We offer silicone mold making technical support and develop new products

8- We offer sample for testing before ordering

9- We can customize logo as per clients’ request

10- We help clients sourcing other related products

Quality Control of mold making liquid rtv2 silicone rubber:

If you are looking for platinum cure(addition cure) silicone, please click the picture below.