Высокопроизводительная силикатная шлифовальная машина

- Категории: Chemical Machinery & Equipment >>>

- Поставщик: Xinxiang,Karp,Machinery,Equipment,Co.,Ltd.Xinxiang,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

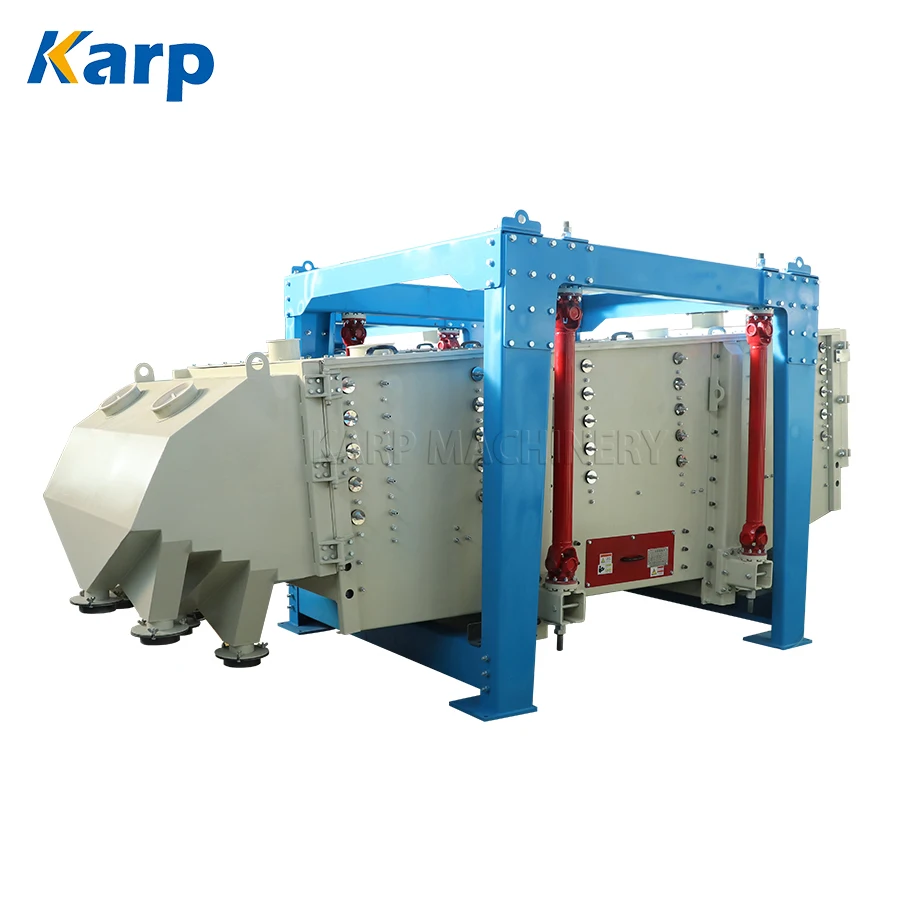

High Capacity Silica Sand gyrasift Screening Machine Gyratory Sifter ceramsite industrial screener separator

Duplex model of gyratory sifters screener

There are two / three / four screening groups works at the same time, to reach a big screening output.

General model of gyratory sifter separator

Max decks: 6 decks.

High Capacity Silica Sand gyrasift Screening Machine Gyratory Sifter ceramsite industrial screener separator offering high capacity screening in a low maintenance, operator-friendly design. The horizontal, uniform gyratory motion provides the highest performance per screen area available on the market, which means sharper separations, higher volume, exceptional screen cleaning, low dynamic force and unparalleled material spread-ability Engineered for maximum uptime and ease of use, the drive is maintenance free, with no lubrication required. These features significantly reduce equipment downtime, leading to greater production capacity. Additional benefits include a high-performance feed box, discharge door and superior deblinding ball action.

Product Paramenters

The common model of High Capacity Silica Sand gyrasift Screening Machine Gyratory Sifter ceramsite industrial screener separator can be produced to 6 layers.

Model | Layer | Effective screening area (m2) | angel (°) | power (kw) | dimension (mm) |

FYBS1030 | 1-6 | 3.0 | 5-10 | 2.2 | 3600*1600*1800 |

FYBS1036 | 3.6 | 2.2 | 4200*1600*1800 | ||

FYBS1230 | 3.6 | 4 | 3600*1800*1800 | ||

FYBS1236 | 4.3 | 4 | 4200*1800*1800 | ||

FYBS1530 | 4.5 | 4 | 3600*2100*2000 | ||

FYBS1536 | 5.4 | 4 | 4200*2100*2000 | ||

FYBS1830 | 5.4 | 5.5 | 3600*2400*2400 | ||

FYBS1836 | 6.48 | 5.5 | 4200*2400*2400 | ||

FYBS2030 | 6.0 | 7.5 | 3600*2600*2400 | ||

FYBS2036 | 7.2 | 7.5 | 4200*2600*2400 |

Details Images

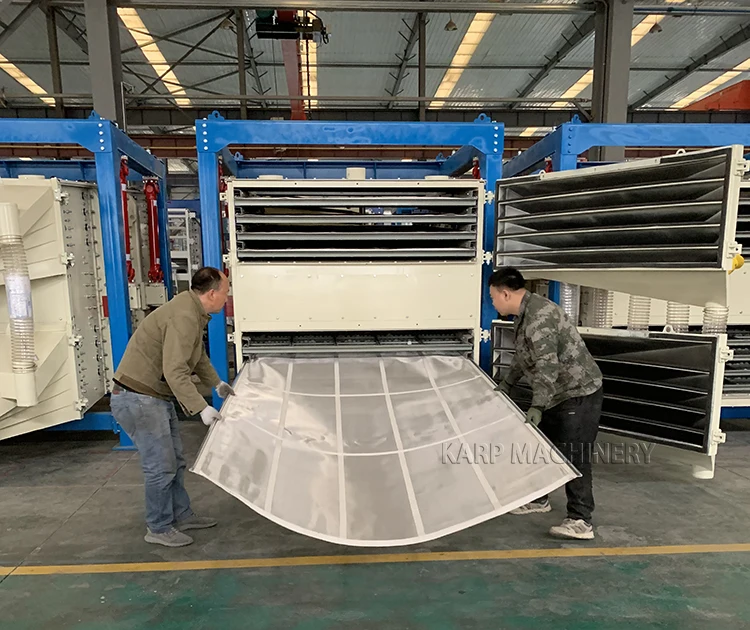

Replace the screen quickly

* It only needs an external hex wrench and an internal hex wrench.

* It only needs an external hex wrench and an internal hex wrench.

* 2 operators can complete the replacement of screen within 10

minutes.

minutes.

The whole sieve box of the vibrating screen is connected by the universal axis, when the sieve machine does the rocking movement, the universal axis also follows the rotation, plays the role of buffering to the rotating power, damping, so that the whole sieve machine runs more smoothly.

Particles absorbed on the mesh line be break up by cleaning systerm, then particles pass through mesh hole easily. Cleaning systerm guarantee the screening capacity and accuracy.

Improve your return on investment

* Compared with the traditional linear vibrating screen: -The space occupation is reduced by 70%. -The energy consumption is reduced by 73%.-The length of the conveyor at the discharge port is reduced by 30%.

CUSTOMER ON-SITE PICTURES

Quality Control

KARPMACHINERY make strict inspections for High Capacity Silica Sand gyrasift Screening Machine Gyratory Sifter ceramsite industrial screener separator before producing, during producing, before shipment. Inspection item include mesh size, mesh cloth tension, motor temprature, dimesion, noisy, vibration amplitude ect. Inspection reach ISO 2194 Wire screens and plate screens for industrial purposes Nominal sizes of apertures.

More pictures

Application photos

High Capacity Silica Sand Screening Machine Gyratory Sifter Polymer Resin Vibrating sieve are good at non-ferrous metals, chemical, food, and other industries, especially for screening heavy alkali, sand, silica sand, salt, resin, fertilizer, urea, feed, reduced iron powder, zirconium oxide, ceramic, barite and etc.

Packing & Delivery

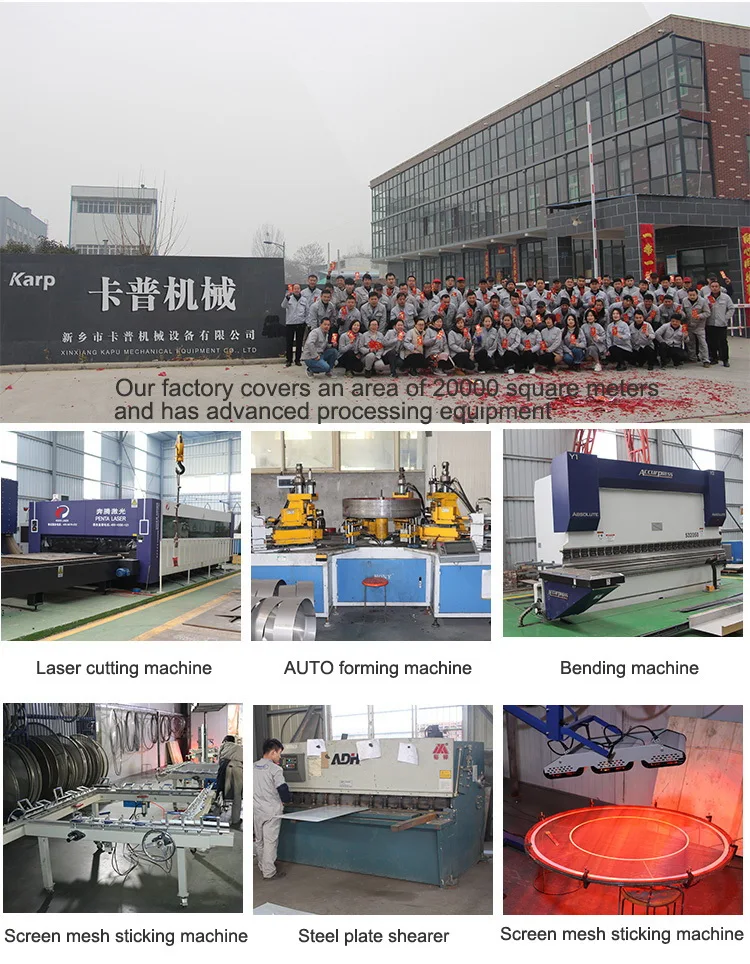

Company Profile

Our service

1. Your sample material can be free analysised in our laboratory.

2. 24 hours/365 days online & quick response within 12 hours.

3. Warranty period: 13month

4. Production lead time and delivery time guaranteed.

5. Help high-end customers to develop the local market

6. All packing and shipping can customized as per your requirements.

Xinxiang KARP Machinery Equipment., Co Ltd is one of leading manufacturer of vibrating screen sifter, conveying machines, feeding machines, elevating machines and related products with 11 years designing and manufacturing experiences.

Our main products are vibrating screen, High Capacity Silica Sand gyrasift Screening Machine Gyratory Sifter ceramsite industrial screener separator, gyratory screen, tumbler screen, screw conveyor, belt conveyor, scraper conveyor, vibration table, standard laboratory inspection sieve, bucket elevator, vibration elevator, vibration motor, vibrating conveyor,feeding machine and related parts. All of our products are widely used in food, pharmaceutical, chemical, metallurgy, building materials, mining, environmental protection and other fields. Warmly welcome friends from all over the worlds to our company, we looks forward to sincere cooperation and mutually beneficial development with you.

We are committed to solve all screening and conveying problems of bulk materials. Depending on the quality as the life of enterprise,we will with professional solution, high quality products, perfect service to win our customers' approval.

We are committed to solve all screening and conveying problems of bulk materials. Depending on the quality as the life of enterprise,we will with professional solution, high quality products, perfect service to win our customers' approval.

Related product

FAQ

Q: Are You a Manufacturer?

A:Yes, 20 years specialized in sieving machine,conveying machine,packing machine.

A:Yes, 20 years specialized in sieving machine,conveying machine,packing machine.

Q: How long for the High Capacity Silica Sand Screening Machine Gyratory Sifter Polymer Resin Vibrating sieve?

A: 7-20 working days.Q: How long for warranty time?

A: 13 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation.

Q: About quality

A: Welcome to our factory and check the quality of product.We will send you the video and pictures before shipment after you order.

A: Welcome to our factory and check the quality of product.We will send you the video and pictures before shipment after you order.