Небольшой туннельный пастеризатор и охлаждающий туннель для циркуляции горячей воды дезинфекции

- Категории: Пастеризатор >>>

- Поставщик: Zhangjiagang,Hengyu,Beverage,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

This machine is one kind of pasteurization machine developed for filling line to get products longer expiration date.It could assure good sterilizing effects , reduce bottle broken rate . Hot water is recycled to use in temperature sections in order to save heat energy and reduce water consumption .This machine could process bottled beverage or beer products , which completely conforms to relevant technologic requirements .It is a necessary secondary sterilization equipment for automatic production line.According to the technological requirements of users for different products, to make different process design, meet the technological requirements, according to user requirements.

configuration of the corresponding high precision automatic control system.Performance characteristics:

1. Equipment rack is full stainless steel, the overall structure is compact, and health appearance.

2, It can be used for various of bottle/can shapes and volumes;

3, Easy construction for easy maintenance;

4, Transparent glass window at entrance and end will make clear of view if any problem happening inside tunnel and open able top

will help for easy problem solving;

5, the recycle water system will help for reducing water consumption;.

6Solid cone wide-angle spray nozzle, the flow distribution uniformly stable, constant temperature field.

7. A variety of comprehensive utilization of heat energy recovery technology, energy saving, environmental protection.

8. Sterilization temperature PLC touch screen control was produced by Germany Siemens company.

9. Frequency conversion control, total processing time can be adjusted according to the production process

Rotatory bottle-rinsing machine has the functions of not opening the valve and rinsing without bottle, which is working from bottle entrance,bottle transportation,bottle clipping,bottle turning around with synchronously rinsing inside of the bottle to water-dropping and exit have the functions of not opening the valve and rinsing without bottles.

Filling heads.

Adopting the way of filling by holding the necks of the bottle, plus the function of pre-cover of the centralizing cover with high precise centralization,which ensure the right seating of mouth of the bottle and filling valve,with low liquid loss.

Capping heads.

This series of automatic glass bottle gas beverage filling machine can meet the filling and sealing requirements of caps, nuts and other different sealing methods.

Adopt magnetic head, transfer torque through strong magnet, adjustable torque, meet the needs of various head.

Flat Conveyor.

<1>Energy saving. High efficient. Adapt to customer factory layout

<2> Special lubrication system, keep products clean, health, safety

<3>Extended service life

<4>Electric eyes design keep whole line running safety and quickly

<5>Overload protection mechanism to effectively ensure the safety of the machine

Technical Parameter

Model (PCGF) | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/10 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 10 | 12 | 15 |

Capacity (BPH) | 2000 | 5000 | 7000 | 9000 | 14000 | 18000 | 24000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension (mm) | 2300*1600 *2500 | 2600*1920 *2550 | 3100*2200 *2800 | 3850*3000 *2850 | 4850*3800 *2750 | 7570*3550 *2750 | 6500*5500 *2750 |

Weight(kg) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 |

Water Treatment System

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

Bottle Blowiing Part

1)Widely used to produce the carbonated bottle,mineral water bottle,pesticide bottle,oil bottle and cosmetics etc.

2)Suitable for producing PET plastic containers and bottles in all shapes.

3)With famous electrical components and have various capacities.

Carbonated Beverage Mixer

1. suitable beverage types: Cola and lemon.

2. mixing ratio range: 3:1 - 6:1

3. CO2 content: 4 times

4. volume: CO2 consumption of about 4 M3/h

5. CO2 supply pressure: 0.8-1 Mpa

6. CO2 Purity: 99.9%

7. consumption of ethylene glycol solution: water=30M3/h

8. ethylene glycol solution pressure: 1.0Mpa

9. ethylene glycol solution inlet temperature: -2 C.

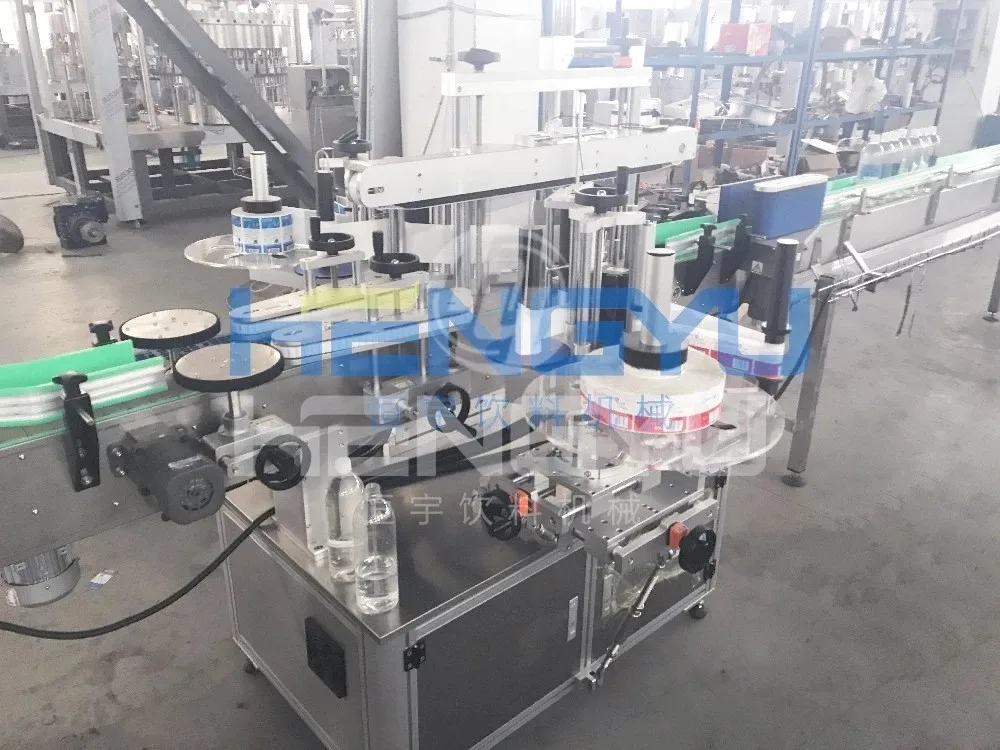

Labeling Part

1)PE film shrink wrapping machine

2)Half-tray shrink wrapping machine

3)Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable

element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished

product.

Packaging Part

1)PE film shrink wrapping machine

2)Half-tray shrink wrapping machine

3)Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.