Автоматическая Машина Для Запечатывания крышек бутылок

- Категории: Укупорочные машины >>>

- Поставщик: Zhangjiagang,Hengyu,Beverage,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Feature:

1) This machine has compact structure, flawless control system, and is convenient to operate with high grade automatism.

2)Full automatic rotary capping machine is unscrambled lid,conveying lid,conveying bottle and capping,it's using the cover positioning screw cap,the whole machine is a rotary structure.

3)In the process of the screw cap, there is no damage bottle,high efficiency, high qualified rate, smooth operation and wide use,which can be compared with similar products abroad.

4)This machine is suitable for all kinds of rules glass or plastic bottle of all kinds of outer cover automatic twist, use the grab cover to grab the various LIDS that are conveyed by the scraping plate, and complete the outer cover in the bottle turning process.The whole machine adopts PLC control, HMI, convenient and easy to operation.

5) Adopts high precision and high speed ration filling valve so that the oil level is exact with loss, ensuring high quality filling.

6) The capping head has constant twisting movement, which ensures capping quality, without damaging caps.

7) Adopts high efficiency cap tidying system, with flawless equipment for feeding caps and protecting.

6) Needs only to change the pinwheel, bottle entering screw and arched board when changing bottle models, with simple and convenient operation.

9) There is flawless equipment for overload protecting, which can protect effectively machine and operator safety.

10) This machine adopts an electromotor with transducer adjusting speed, Andis convenient to adjust productivity.

Technical parameters

Model(CGF) | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/12 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 12 | 12 | 15 |

Capacity(BPH) | 4000 | 7000 | 11000 | 13000 | 18000 | 24000 | 28000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension(mm) | 2400*1650*2500 | 2600*1920*2550 | 3100*2100*2800 | 3800*2800*2900 | 4600*2800*2900 | 5450*3300*2900 | 6500*4500*2900 |

Weight(kg) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 | 12800 |

Detail Images

1)Into bottle way is air conveyor direct connection with Bottle dial .

2)All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3)304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4)304/316 stainless steel washing pump make the machine more durable .

Filling heads

1)304/316 Stainless steel high precision filling nozzle

2) Filling volume adjustable in fine rank, same liquid level after filling

3)All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5)Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2% .

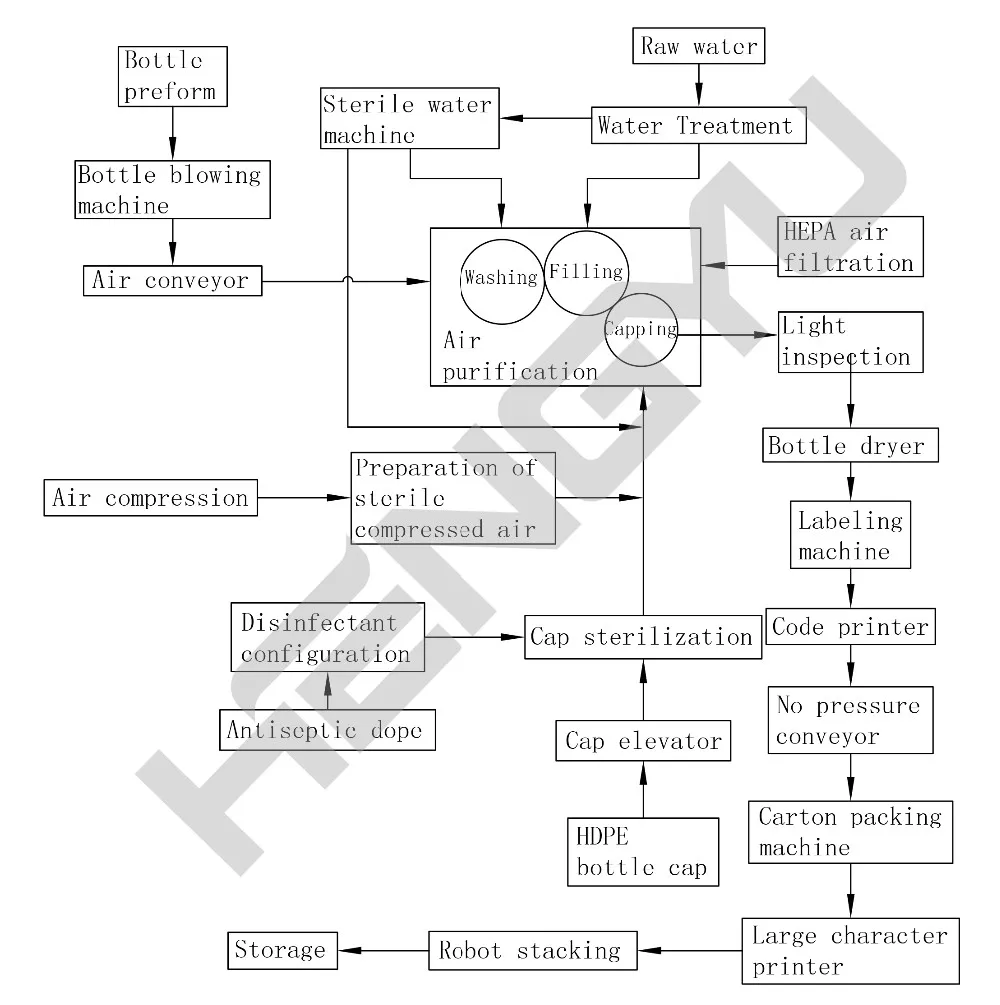

Water Treatment System

1)Stainless steel high pressure film shell

2)All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3)Online type pressure auto self-protection device

4)Online type electricity indicator (with stable compensation)

5)System safe protecting and alarm system

6)System frame

Reverse Osmosis

The reverse osmosis can remove more than 97% of the soluble salt and above 99% of the colloid, microorganism, particles and organic materials, becoming the best first-choice choice equipment in the engineering of modern purified water, highly purified water and space water (super-purified water). The most highlighted features are low energy consumption, no pollution, simple technique, high-quality water and convenient operation and maintenance.

Bottle Blowiing Part

1)Widely used to produce the carbonated bottle,mineral water bottle,pesticide bottle,oil bottle and cosmetics etc.

2)Suitable for producing PET plastic containers and bottles in all shapes.

3)With famous electrical components and have various capacities.

Labeling Part

1)Heat shrink sleeve labeling machine

2)OPP Hot melt labeling machine

3)PVC label stick labeling machine

The running of complete machine is stable and at high speed with the use of imported servo control system.Using of special bottle-distributing mechanism to avoid the materials being scrached and with which the machine can be adjusted and located quickly to label bottles with any diameter without replacing accessories.

Packaging Part

1)PE film shrink wrapping machine

2)Half-tray shrink wrapping machine

3)Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.