Простая машина для смешивания СО2 безалкогольных напитков запасные части Южной Кореи Аргентины Индонезии Филиппин предоставляется Саудовская Аравия

- Категории: Смеситель >>>

- Поставщик: Zhangjiagang,Hengyu,Beverage,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Automatic Carbonated Drink CO2 Mixer.

Applications:

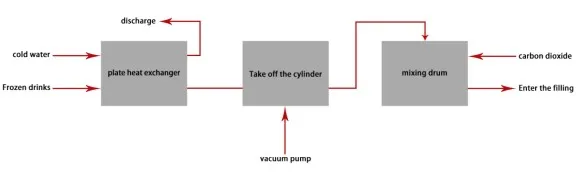

This mixer adopts advances gas-liquid mixing device,can mix syrup,water and CO2 gas at the same time for filling machine.

Also it can apply to thin beer,aerate for beer and produce sparking wine.

This mixer is advances in technology,even in mixing,reliable in performance,compact in structure,easy in operation. It adopts foreign advanced technology-static mixer to lighten water layer, increase carbonizing time, assure mixing result and deoxying. It adopts high-quality water pump and SEIMENS electrical equipment and other parts to form complete automatic control system. It has coordinating action, beautiful appearance, convenient washing, high automatic level and other advantages. It is suitable for mixing all kinds of drink, such as soda water, fruit juice, cola and other soft and hard drink.

It is suitable for aerated beverage firm of large,middle or small scale.

Main technical standards:

Model | PMH-1000 | PMH-2000 | PMH-3000 | PMH-5000 | PMH-8000 |

Capacity(L/H) | 1000 | 2000 | 3000 | 5000 | 8000 |

Content of co2 | 3.2-4 | 3.2-4 | 3.2-4 | 3.2-4 | 3.2-4 |

Mixing temperature | <4℃ | <4℃ | <4℃ | <4℃ | <4℃ |

Power(KW) | 1.5 | 2.97 | 3 | 5.9 | 7.2 |

1)This drink filling machine carbonated is mainly used to fill the carbonated drink.

2)Washing,filling and capping are available in one machine.

3)The structure of conveying is hanging type and clamping the bottleneck to easily change bottle type.

4)The filling method adopts the isobaric filling so that the filling speed is faster and stable.

5)Using the advanced PLC(Programmable Logic Controller) technology.

6)The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON.

Washing heads.

1)Into bottle way is air conveyor direct connection with Bottle dial .

2)All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3)304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4)304/316 stainless steel washing pump make the machine more durable .

Filling heads.

1)304/316 Stainless steel high precision filling nozzle

2) Filling volume adjustable in fine rank, same liquid level after filling

3)All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5)Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads.

1)Heat shrink sleeve labeling machine

2)OPP Hot melt labeling machine<in picture>

3)PVC label stick labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.