Машина для переработки пищи собак и кошек Высококачественная линия

- Категории: Оборудование для производства напитков и пищи >>>

- Поставщик: Shandong,Arrow,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

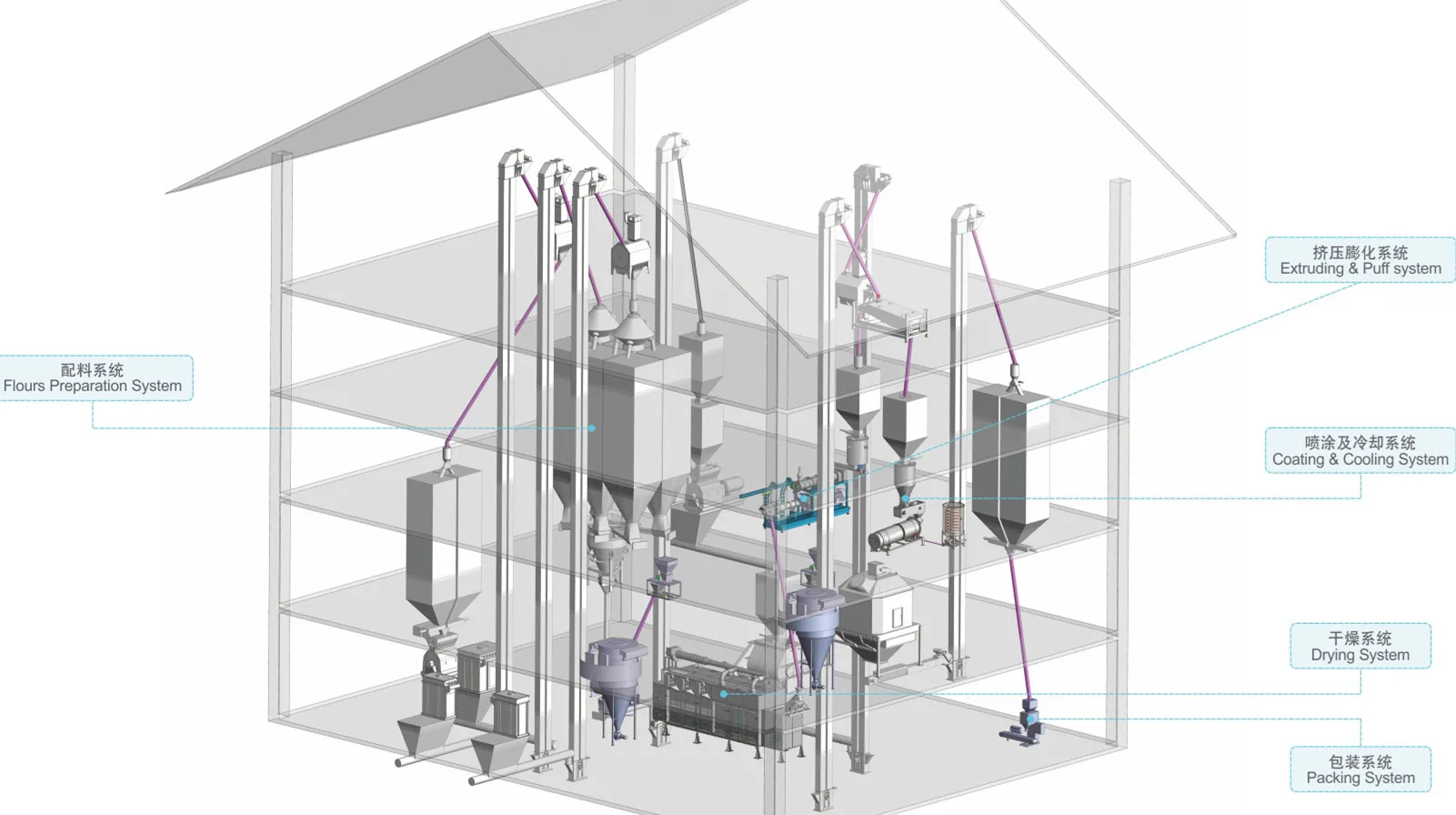

Process line

Products Description

General Description: With the growing variety of pet food, the demand for pet food and the market demand is increasing, and our company has developed various pet food lines and processing line based on the market demand. According to the variety of products, our production line covers various configurations such as staple foods, snacks, toys. By changing parameters such as raw materials, temperature, humidity, etc. Parameters, new style foods, rich in nutrients, perfect textures, can meet the needs of different animals for adaptability and better taste.

Application: pet food, chew food, pet treat.

Capacity: 500 kg / h or less, 800 ~ 1200 kg / h, 1500 ~ 2500 kg / h, 2500 ~ 3500 kg / h and 4500 kg / h ~ 6000 kg / h.

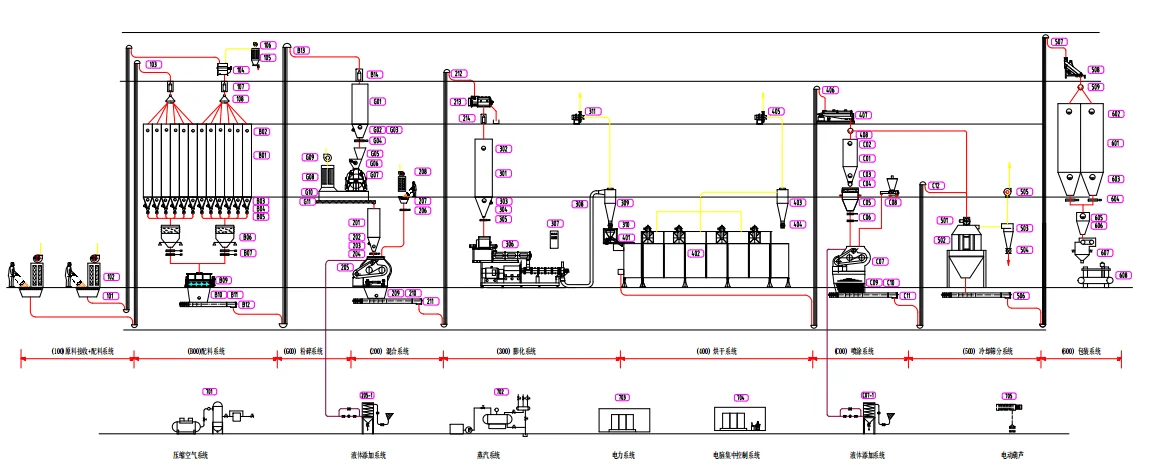

Flow chart:

Our engineer could design the layout drawing according to your dimension of the factory for the pet food production line.

Application: pet food, chew food, pet treat.

Capacity: 500 kg / h or less, 800 ~ 1200 kg / h, 1500 ~ 2500 kg / h, 2500 ~ 3500 kg / h and 4500 kg / h ~ 6000 kg / h.

Flow chart:

Our engineer could design the layout drawing according to your dimension of the factory for the pet food production line.

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Product sample

Main equipments Description

Name | Mixer |

Usage | To mix the raw materials evenly, fast speed, no leakage. |

Capacity | 500kg/h-6000kg/h |

Raw material | Carbon steel |

Name | AYT series twin screw extruder |

Usage | To extrude the raw materials and make them to the required shape and size of the pet food pellets by mould |

Capacity | 500kg/h-6000kg/h |

Raw material | Stainless steel/Carbon steel |

Name | Dryer |

Usage | To dry the feed pellets produced by the extruder at high temperature, remove part of the water. |

Capacity | 500kg/h-6000kg/h |

Raw material | Stainless steel/Carbon steel |

Name | Flavoring machine |

Usage | To mix the oil and flavors on the surface of the pet food |

Capacity | 00kg/h-6000kg/h |

Raw material | Stainless steel/Carbon steel |

Core characteristic

AYT fantastic technology conical twin screw extruder

(1) Design: Developed by 3D software, analog simulation, and it has been tested by a computer automatically, in order to ensure

the accuracy of the design requirements.

(2) Concept: Modular function, humanized menu system, various applications are always our pursuit. AYT double screw extruder for

advanced design concepts can meet different requirements.

(3) Profession: We have a professional and manufacturing industry to ensure the precision and coordination of each component of

the extruder, while maintaining stable processing and low noise.

(4) Precision: Precise food manufacturing technology and material selection that ensure cable life is superior to extruder

products, to minimize screw and barrel wear.

(5) Experience: More than twenty years of experience in domestic and international advanced double screw extruder. We produce

various kinds of food extrusion, such as vegetable protein, cereal flakes / breakfast cereals, pellets, feed / animal feed, etc.,

enough to solve the problems met during production.

the accuracy of the design requirements.

(2) Concept: Modular function, humanized menu system, various applications are always our pursuit. AYT double screw extruder for

advanced design concepts can meet different requirements.

(3) Profession: We have a professional and manufacturing industry to ensure the precision and coordination of each component of

the extruder, while maintaining stable processing and low noise.

(4) Precision: Precise food manufacturing technology and material selection that ensure cable life is superior to extruder

products, to minimize screw and barrel wear.

(5) Experience: More than twenty years of experience in domestic and international advanced double screw extruder. We produce

various kinds of food extrusion, such as vegetable protein, cereal flakes / breakfast cereals, pellets, feed / animal feed, etc.,

enough to solve the problems met during production.

Product packaging &delivery

Company Introduction

Shandong Arrow Machinery Co., Ltd. is a company specializing in R&D, production, sales, application promotion of food engineering

projects. As a professional food processing equipment &whole plant engineering problem solvers in China, machines served for more

than 970 companies, export to 116 countries, more than 20 years engineering team. We aim to create a great future together with

global customers.

* More than 15 years experience

* Professional design,fabrication,installation team

* Professional R&D center

projects. As a professional food processing equipment &whole plant engineering problem solvers in China, machines served for more

than 970 companies, export to 116 countries, more than 20 years engineering team. We aim to create a great future together with

global customers.

* More than 15 years experience

* Professional design,fabrication,installation team

* Professional R&D center

FAQ

Q: What kinds of products can be made?

A: corn flakes, puffs, breakfast cereals food, animal feed, animal feed, soy protein texture food.

Q: What's the delivery time?

A: We usually need 40-45 days for large sizes, depends on the finished product, so machine wash-change.

Q: What about the installation service?

A: Depending on the whole line of equipment price list, it usually takes 2-3 weeks. We will provide you with installation instructions, such as start, as well as their operation machines for quality control, testing of different recipes.

Q: What is the warranty period for using the device?

A: 1 year for auger and cylinder due to modular design, changing the wearing parts will be OK, unlike a full set of screws, no

need to change the whole set.

A: corn flakes, puffs, breakfast cereals food, animal feed, animal feed, soy protein texture food.

Q: What's the delivery time?

A: We usually need 40-45 days for large sizes, depends on the finished product, so machine wash-change.

Q: What about the installation service?

A: Depending on the whole line of equipment price list, it usually takes 2-3 weeks. We will provide you with installation instructions, such as start, as well as their operation machines for quality control, testing of different recipes.

Q: What is the warranty period for using the device?

A: 1 year for auger and cylinder due to modular design, changing the wearing parts will be OK, unlike a full set of screws, no

need to change the whole set.