Высоконадежная устойчивая к коррозии Электромагнитная проводящая прокладка черная

- Категории: Защитная упаковка >>>

- Поставщик: Foshan,Shunde,Ronggui,Aigao,Foam,Rubber,Products,Factory

Поделиться:

Описание и отзывы

Характеристики

Conductive foam cloth sliver is composed of conductive cloth wrapped with conductive foam . There is a hot melt adhesive between conductive cloth and conductive foam . The hot melt adhesive binds conductive cloth and conductive foam into one structure. On the outer side of conductive cloth, there is a conductive adhesive for fixing conductive cloth foam sliver.

| Surface Resistance: | ≤0.03Ω/inch |

| Shielding Effect: | 60dB~90dB/30MHz~3GHz |

| Heat-resisting Temperature: | - 40 ℃ - 120 ℃ |

| Frictional Resistance: | above 400,000 times ASTND4966-98 |

| Metal Layer Binding Force: | more than 4 AATCC TM8-2001 |

| Tensile Strength: | 1.3 (kg / 25 mm) |

| Initial Adhesion: | 1200 g / 25 mm |

| Maintain Adhesion: | 4000 Min/inch |

| Fire Rating : | UL94V0. 94 (HF - 1) |

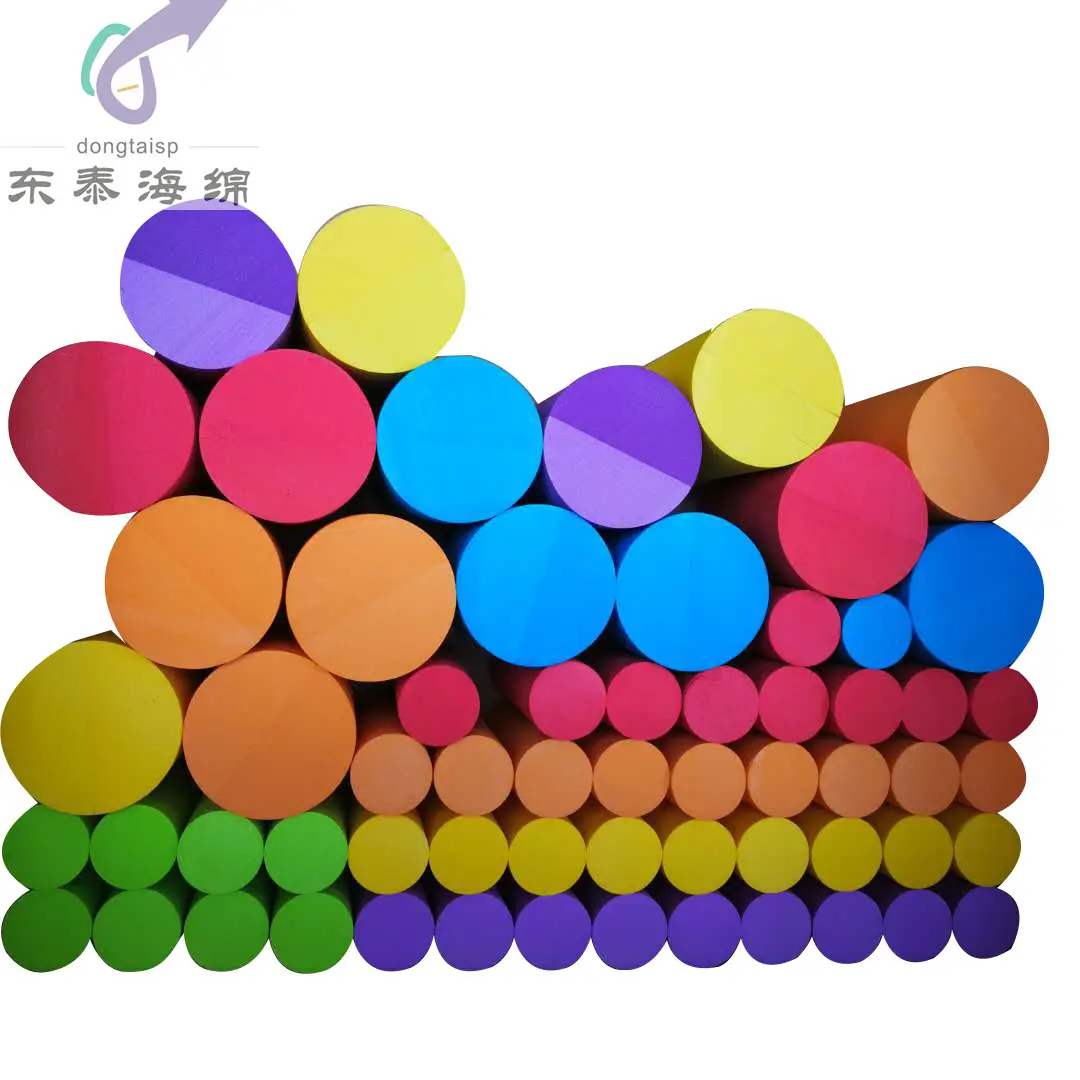

Conductive foam can be divided into Conductive foam can be divided into ordinary conductive foam, nickel-plated copper conductive foam, gold-plated conductive foam, carbon-coated conductive foam, tin-plated conductive foam, conductive aluminum foil foam, conductive copper foil foam, all-round conductive foam , SMT conductive foam, I / O conductive foam pad, etc.

Conductive foam are widely used in the plasma TV, LCD monitor, LCD TV, mobile phone, Laptop PC, Desktop PC, PDA, MP4, communications cabinets, medical instruments and other electronic products.

Conductive foam is also widely used in PDP TV, LCD display, notebook computer, MP3, communication cabinet, medical equipment and other electronic products as well as military and aerospace fields, specifically for conductive parts in electronic products, such as antenna modules, tail plugs At the office, at the earpiece, at the seal of the chassis, etc.

Its main function is shielding and conduction.