Высокое Качество комбинированные для закалки стекла печь из гнутого с микрокомпьютерным

- Категории: Glass Production Machinery >>>

- Поставщик: Zhejiang,Hanneng,Glass,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Working Factory

More than 30,000 Square meter working factory. Capacity: more than 50set per year

Specification

Model | Max Glass Size(mm) | Min Glass Size(mm) | Thickness (mm) | Power(KVA) | ||||

Flat Glass | Bent Glass | Flat | Bent | |||||

HNAB1208 | —— | 1250x850 | —— | 200x350 | 2.5-19 | 250 | ||

HNAB2010 | —— | 2000x1000 | —— | 200x350 | 2.85-19 | 390 | ||

HNAB2417 | —— | 2440x1700 | —— | 200x400 | 4-19 | 650 | ||

HNA1236B08 | 1250x3660 | 1250x850 | 100x250 | 200x350 | 2.5-19 | 330 | ||

HNA2025B08 | 2000x2500 | 2000x850 | 100x250 | 200x350 | 4-19 | 330 | ||

HNA2436B10 | 2440X3660 | 2000×1000 | 100x250 | 200x350 | 4-19 | 380 | ||

HNA2436B17 | 2440X3660 | 2440x1700 | 100x300 | 200x400 | 4-19 | 580 | ||

HNA2442B17 | 2440X4200 | 2440x1700 | 100x300 | 200x500 | 4-19 | 630 | ||

HNA2442B20 | 2440X4200 | 2440x2000 | 200x400 | 200x500 | 4-19 | 760 | ||

HNA2442B25 | 2440X4200 | 2440x2500 | 200x400 | 200x500 | 4-19 | 760 | ||

HNA2450B20 | 2440X5000 | 2440x2000 | 200X400 | 200X500 | 4-19 | 890 | ||

HNA2450B25 | 2440X5000 | 2440x2500 | 200X400 | 200X500 | 4-19 | 700 | ||

HNA2860B20 | 2800X6000 | 2800X2000 | 200X500 | 200X500 | 5-19 | 1000 | ||

HNA3380B20 | 3300X8000 | 3300X2000 | 200X600 | 200X500 | 5-19 | 1500 | ||

HNA33160B25 | 3300x16000 | 3300X2500 | 200X600 | 200X500 | 5-19 | 2800 | ||

Company Profile

Product Description:

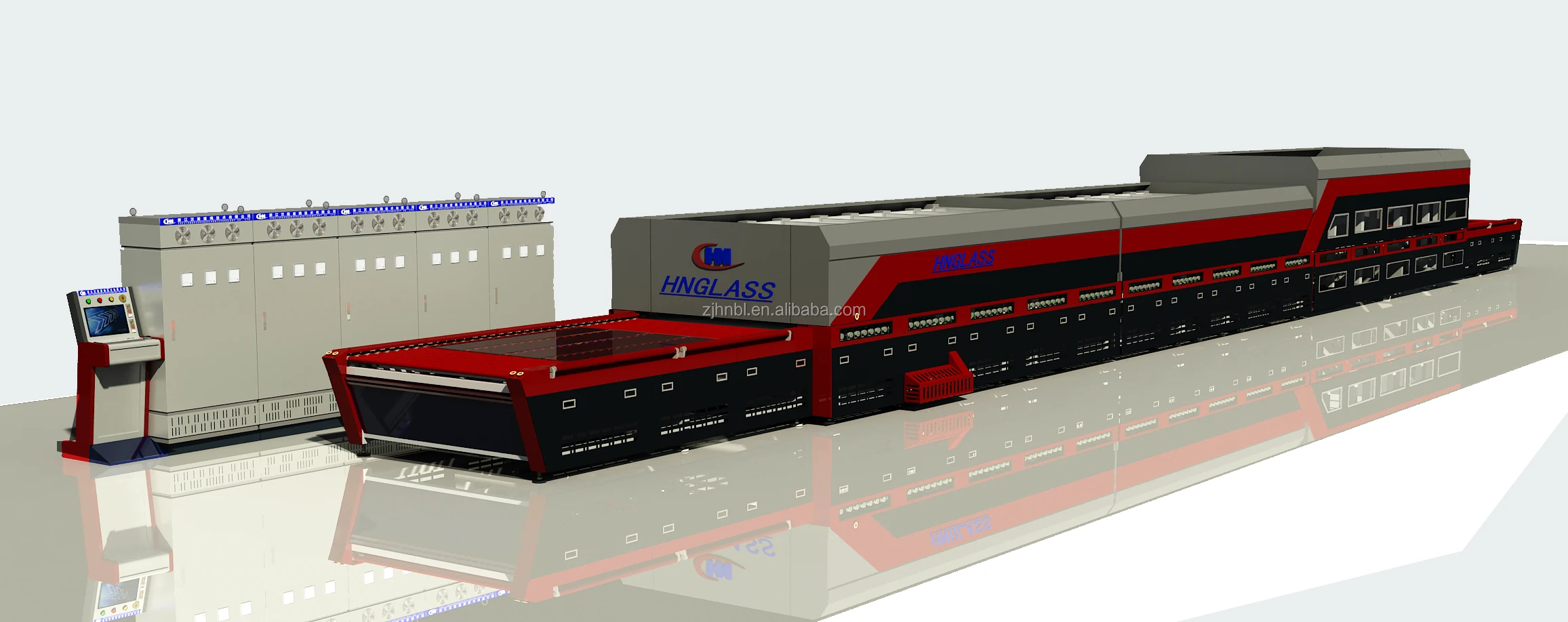

Combined Bi-directional Flat and Bend glass tempering machine is a special plant used to produce the flat and bent tempered glass, which mainly used in the fields of architecture (doors, windows), home applicants, Automobile bus side glass, shower room, garden fence, elevator, etc.

Combined Bi-directional Flat and Bend glass tempering machine is a special plant used to produce the flat and bent tempered glass, which mainly used in the fields of architecture (doors, windows), home applicants, Automobile bus side glass, shower room, garden fence, elevator, etc.

Features of the glass tempering furnace.

1.Stainless Steel Ceramic plates installed at the top of heating elements, which could ensure more even heating, avoid dust falling

2. Ceramic rollers driven by double belts, which can ensure better simultaneous and stable running.

3. Top quality insulating materials for whole heating oven

4. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality.

5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

2. Ceramic rollers driven by double belts, which can ensure better simultaneous and stable running.

3. Top quality insulating materials for whole heating oven

4. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality.

5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

Supply Scope:

1. Loading table

2. Heating section

2. Heating section

Force convection system as option ( Compressed air or Turbo Blower )

Vesuvius ceramic roller as option

3. Flat tempering & cooling section

4. Bent tempering & cooling section

5. Unloading table

6. Blower system with Frequency converter

7. Electrical & control system (Siemens PLC, Computer, etc)

8. Technical documents

3. Flat tempering & cooling section

4. Bent tempering & cooling section

5. Unloading table

6. Blower system with Frequency converter

7. Electrical & control system (Siemens PLC, Computer, etc)

8. Technical documents

Double Heating Chamber Glass Tempering Furnace

Continuous Glass Tempering Furnace

Convection Heating Glass Tempering Furnace

Soft Roller Length Bending Glass Tempering Furnace

Mould Bending/Car glass Tempering Furnace