Пользовательский автоклав для обработки древесины сделано в Китае дешевая цена

- Категории: Другое деревообрабатывающее оборудование >>>

- Поставщик: Shandong,Mosen,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

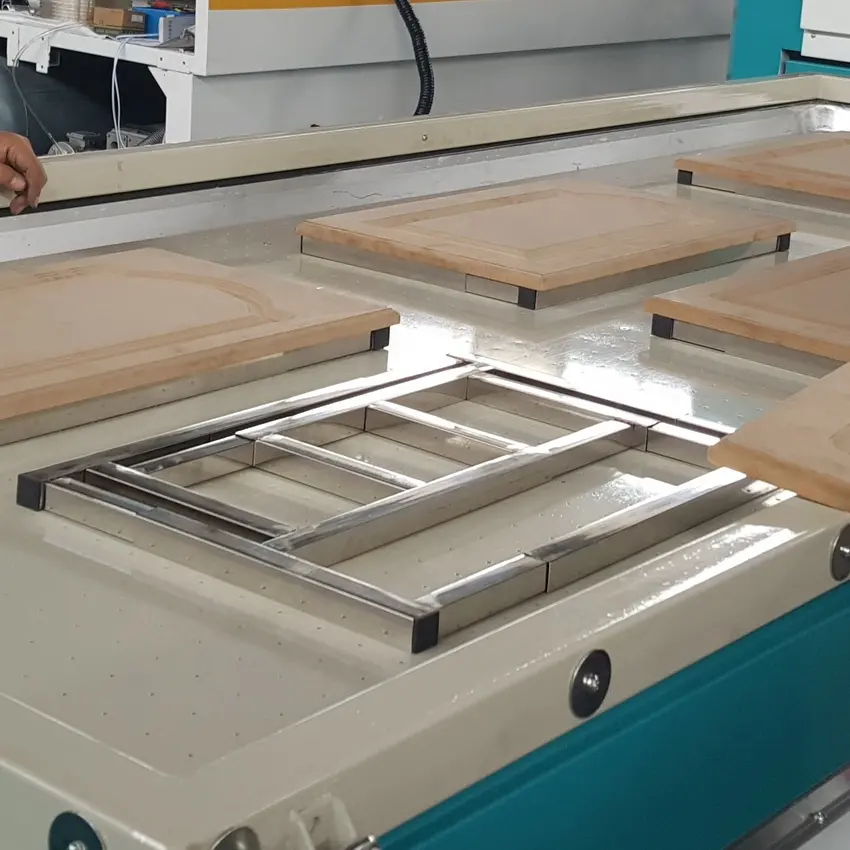

In view of the problems of wood, such as easy to decay, easy to deform, easy to crack and so on, taking all kinds of solid wood board as raw materials, through optimizing the treatment process and vacuum pressure treatment process, the performance of log board in anti-corrosion, anti moth, anti mildew, waterproof, flame retardant, anti deformation, anti cracking has been greatly improved, and the density and hardness of wood can be adjusted according to the requirements.

The density, hardness and bending strength of wood after optimization are better than those before optimization, so as to improve the performance and prolong the service life of wood. The original natural properties of wood, such as heat insulation, temperature control and humidity control, are retained. The color is bright and bright. The physical stripe has strong three-dimensional sense, and the color of the board is transparent and natural. Achieve environmental protection products, environmental protection standards.

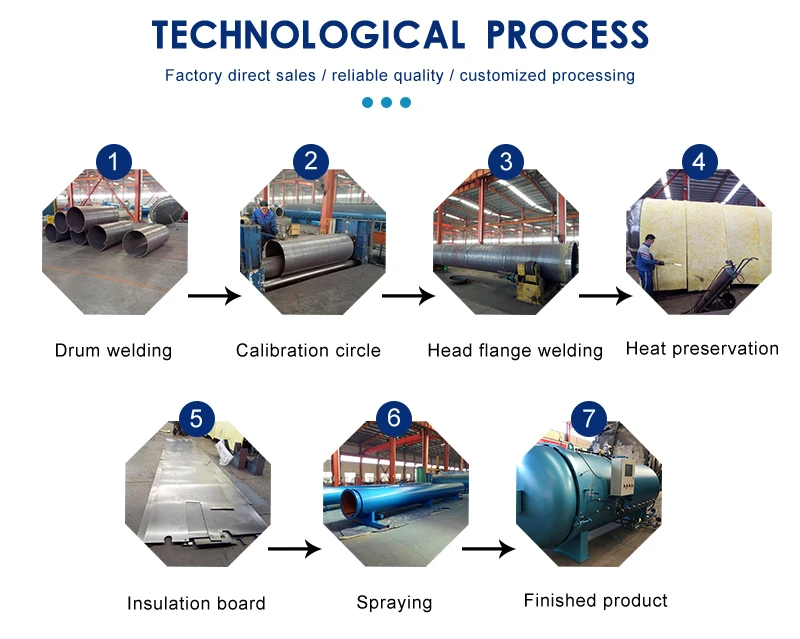

This equipment can process all kinds of wood, such as antisepsis, cooking, coloring, bending, flame retardant, carbonization, drying and so on. Material: carbon steel Q345R or 304 stainless steel, design pressure: 1.58mpa, design temperature: 180 degrees. The length is determined according to the volume of wood, and can also be designed and customized according to the requirements of users, which can meet the technical requirements of different products to a great extent.

| MODEL | OVERSIZE | Diamter (mm) | Length (mm) | Capacity (m³) | D Pre. (MPa) | D. Vacuum

| Voltage (V) | ||

| L | W | H | |||||||

| DL1-8A.2 | 9000 | 1600 | 2000 | 1000 | 8000 | 6.28 | 1.0 | -0.085MPa | 380 |

| DL1.5-8A.2 | 9000 | 2100 | 2500 | 1500 | 8000 | 14.1 | 1.0 | -0.085MPa | 380 |

| DL1.7-8A.2 | 9000 | 2300 | 2700 | 1700 | 8000 | 18.1 | 1.0 | -0.085MPa | 380 |

| DL1.7-12A.2 | 13000 | 2300 | 2700 | 1700 | 12000 | 27.2 | 1.0 | -0.085MPa | 380 |

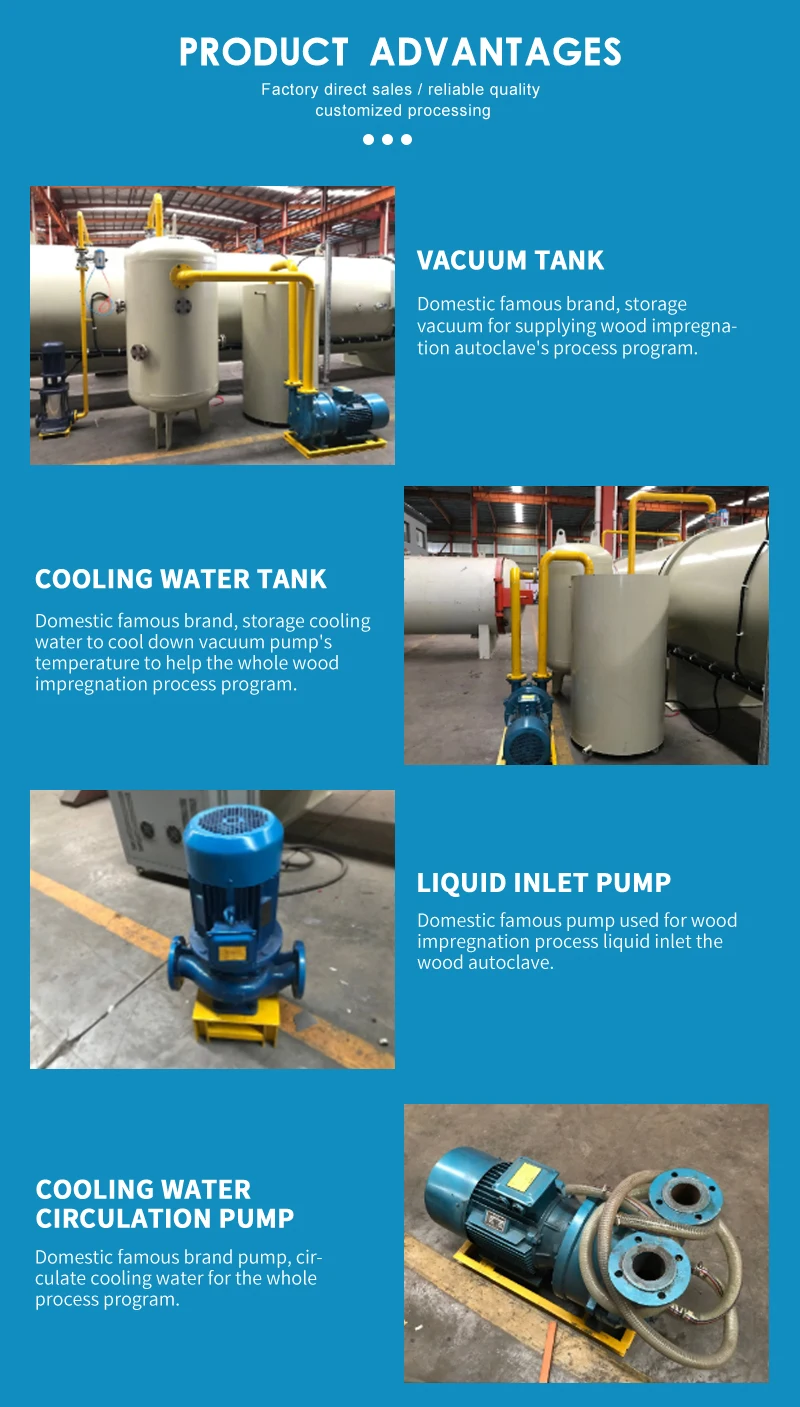

Vacuum and high pressure impregnation:

It is a physical process that preservatives are injected into wood by vacuum and high-pressure impregnation. In this physical process, the chemical reaction process of some preservative active components with starch, cellulose and sugar in wood is realized. This process destroys the living environment of bacteria and insects that cause wood decay, and effectively improves the outdoor preservative performance of wood. Vacuum and high pressure impregnation are the most important processes of anticorrosion treatment.

High temperature characterization:

At high temperature, the preservative can penetrate into the wood as evenly as possible, and the chemical reaction between the preservative and starch, cellulose and sugar in the wood can be completed. Through the qualitative analysis of high temperature, the survival environment of bacteria and insects causing wood decay was further destroyed, and the anticorrosion performance of anticorrosive wood was greatly consolidated and enhanced.

Natural air drying:

Under the test of natural conditions, the preservative can be fully fixed as far as possible, the wood performance is more stable, and the original appearance can be well maintained when using, showing the overall beauty.

Outdoor garden landscape is more and more integrated into our life, whether it is public leisure places, lakeside plank road, tourist attractions, outdoor baths, roadside flower beds, villa gardens, courtyard footpaths, wooden bridges, flower racks, fences and so on, without exception, can not do without preservative wood. Railway sleepers, mine sleepers, bridge sleepers and other engineering construction also need a large number of anti-corrosion sleepers.

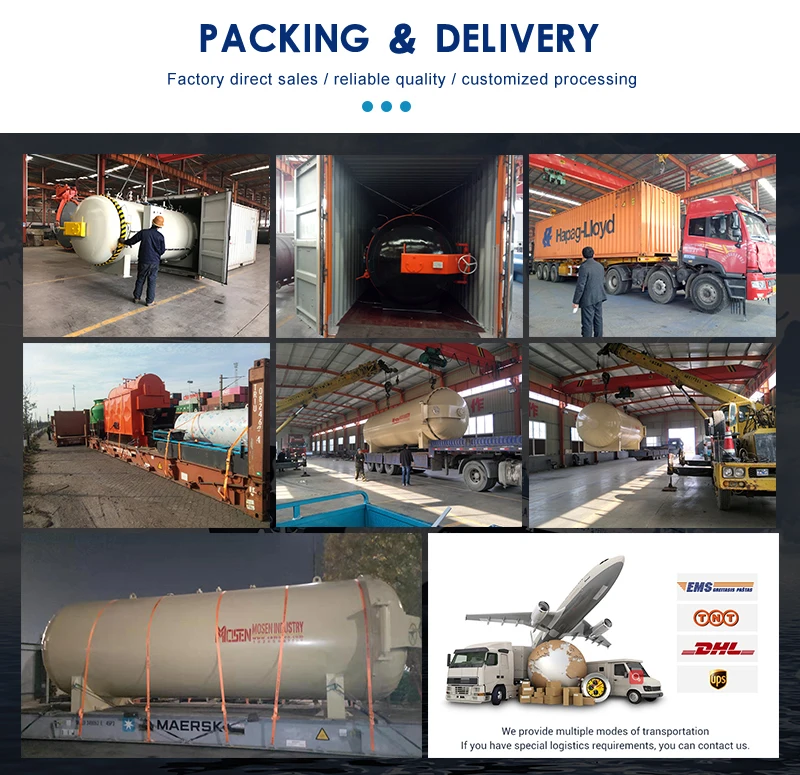

Shandong Mosen Machinery Co., Ltd. is a pressure vessel manufacturer under Mosen Industrial, which integrates scientific research, production and sales. The company is located in Zhucheng High-tech Industrial Park, Shandong Province, close to Qingdao seaport and airport, and the transportation is very convenient.

The company has long been committed to the design and fabrication of pressure vessels such as food sterilization and cooking equipment, rubber vulcanization equipment, wood treatment equipment and harmless treatment equipment. The main products are: sterilization retort autoclave, jacketed kettle, vacuum concentration tanks, vacuum reaction tanks, rubber vulcanization autoclave, wood vacuum impregnation autoclave, drying carbonization autoclave, food packaging machines and other mechanical equipment.

Q: Are you manufacturer or trading company?

A: We are a professional manufacturer.

Q: Where is your factory located?

A: Our factory is located in Zhucheng, Shandong, China. From Qingdao where closes to us 1.5 hours to Beijing, 1.75 hours to Shanghai, 4.5 hours to Guangzhou by air.

Q: What is your business scope?

A: There are three categories, such as food sterilization machine, jacket cooker, rubber vulcanization autoclave.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm or you can come here to conduct investigation.

Q: Will you charge us for drafting if we have special requests?

A: No, we will not. Free of charge to make a draft or offer.

Q: How long the warranty will be?

A: 1 Year warranty.

Q: How about the installation? And what if the machine goes down?

A: We will do that. There are two options.

a. We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on your side.

Q: Do you take L/C?

A: Yes, we accept L/C, T/T and irrevocable L/C payable.

Q: Can we become your distributor in our country?

A: Yes, welcome you! More details will be discussed if you are interested in being our agent.