Круглый нож машина для резки ткани с рисунком 2030 режущие машины приводным вращающимся ножом Осциллирующий режущий

- Категории: Textile Machinery >>>

- Поставщик: Acctek,Machinery,Co.,Ltd.,(shandong)

Поделиться:

Описание и отзывы

Характеристики

Main features:

1. its cutting speed is 5-8 times faster than laser cutting machine.

2. Advanced computerized CNC system, which is easy to operate with Ethernet port.

4. Oscillating knife cutting machine can cut soft materials with perfect edges and corner.

5. Oscillating knife cutting machine adopts Japan YASKAWA servo motor and drive,fast cutting speed with high precision.

6. Oscillating knife cutting machine can be equipped with different tools to meet a variety of needs.

7. Special safety sensing device meets the European standard.

Application:

Oscillating Knife Cutter is used for cutting Leather, Gasket, PP, PE, EVA, PTFE, ETFE, Carpet, Carton, Wood, MDF, PVC, Acrylic,Carboard, Rubber,

Corrugated box, Foam, Leather strip, Composites, Cardboard, Corrugated board, Honeycomb paper, Plastic film,Fiber paper, Plastic box, Rebound rubber, Rubber cloth, etc.

CNC Oscillating Knife Cutter is widely used in Sign and Graphics, Digital Printing, Packaging, Automotive,

Recreational boat,Exhibits and Fixtures, Sign Making, Gasket Materials, Arts and Crafts and other industries.

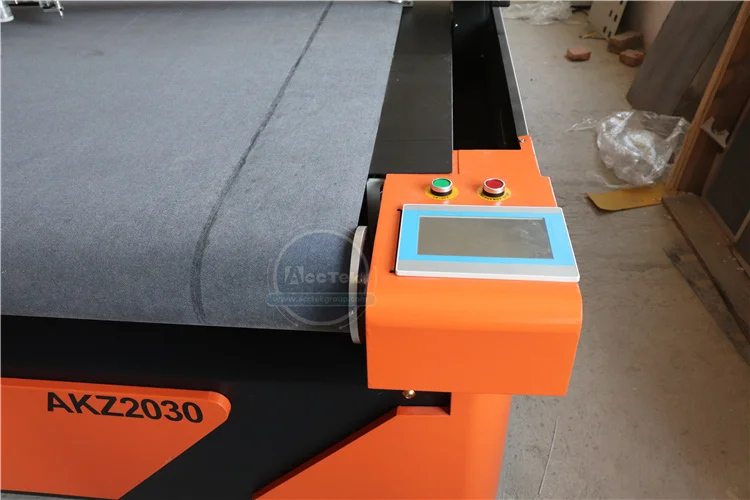

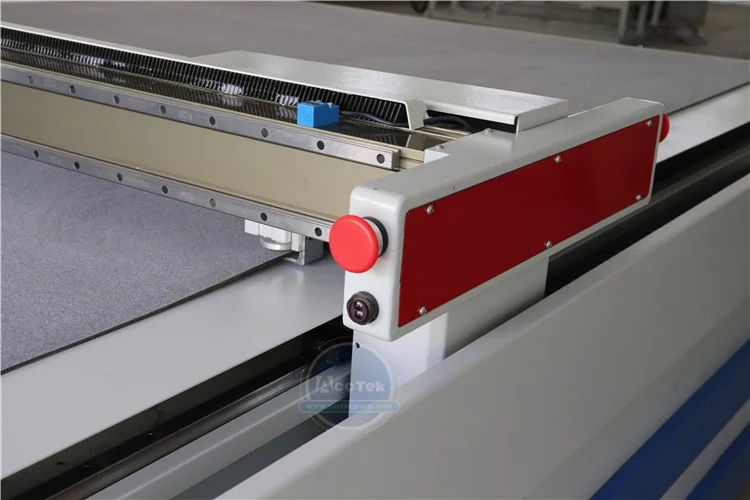

Details of akz2030 knife cutting machine:

Can achieve automatic layout and accurate calculation thus accurately calculating costs,

accurately controlling material distribution, and truly realizing the digital zero inventor strategy.

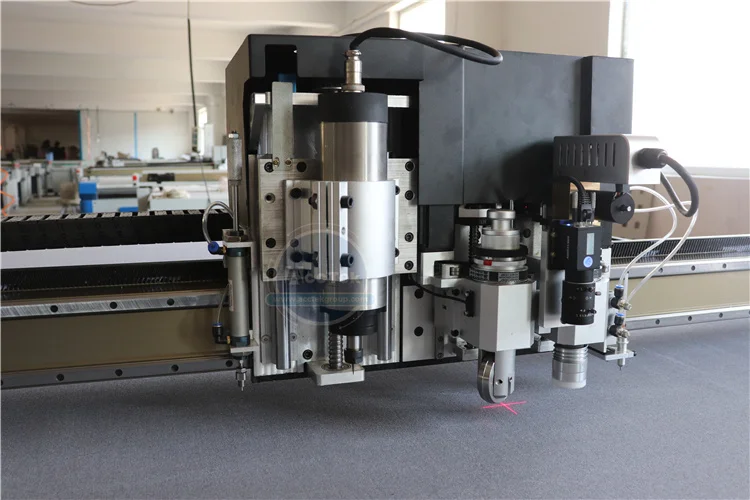

Servo motor and drivers

Taiwan Delta servo motor and drivers, more reliable and with higher working accuracy.

Multiple change head

Multiple tool heads, Quick replacement for different materials.

Safety device

Being equipped with infrared sensor and emergency stop devices at the sides of the machine, safety is guaranteed.

Samples:

Aftersale Service :

* User manual and Installation video will be sent to you together with machine.

* Provide online technical support, and, the engineer can be sent to your local to install or adjust if necessary.

* 3 years guarantee of the whole machine.

* 18 months warranty for Main parts(excluding the consumables and belongs to the user irregularities operating), shall be changed

free of charge if there is any quality problem during the warranty period.

* Provide the consumable parts at an agency price when you need replacement in future.

FAQ:

Q1: 1. How can I choose a suitable Knife cutting machine?

A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut? Are they rolled or not? Breathable or not?

2)What's the largest size of original materials?

3)What's the thickness of materials?

4)Excepting for cutting, do you need more functions, like drawing, punching holes, scanning, feeding, CCD camera, etc.?

Q2: I knew nothing about machine, How can I get the best one for me?

Pls you tell us your working material, detail work by picture or video so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We'll send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can talk by phone, email or other contact ways.

Q4: If the machine has problem in my place, how could I do?

We could send free parts to you in warranty period if machines have any problem under "normal use".

Q5: How long is the delivery time?

For standard machines, it would be 7-10 workdays; For non-standard machines and customized machines according to your specific requirements, it would be 20 to 30 workdays.

Q6: Are you a Factory or Trading company?

We're a professional manufacturer with export license.