Нож для резки бумаги из вольфрамовой стали

- Категории: Промышленные лезвия и ножи >>>

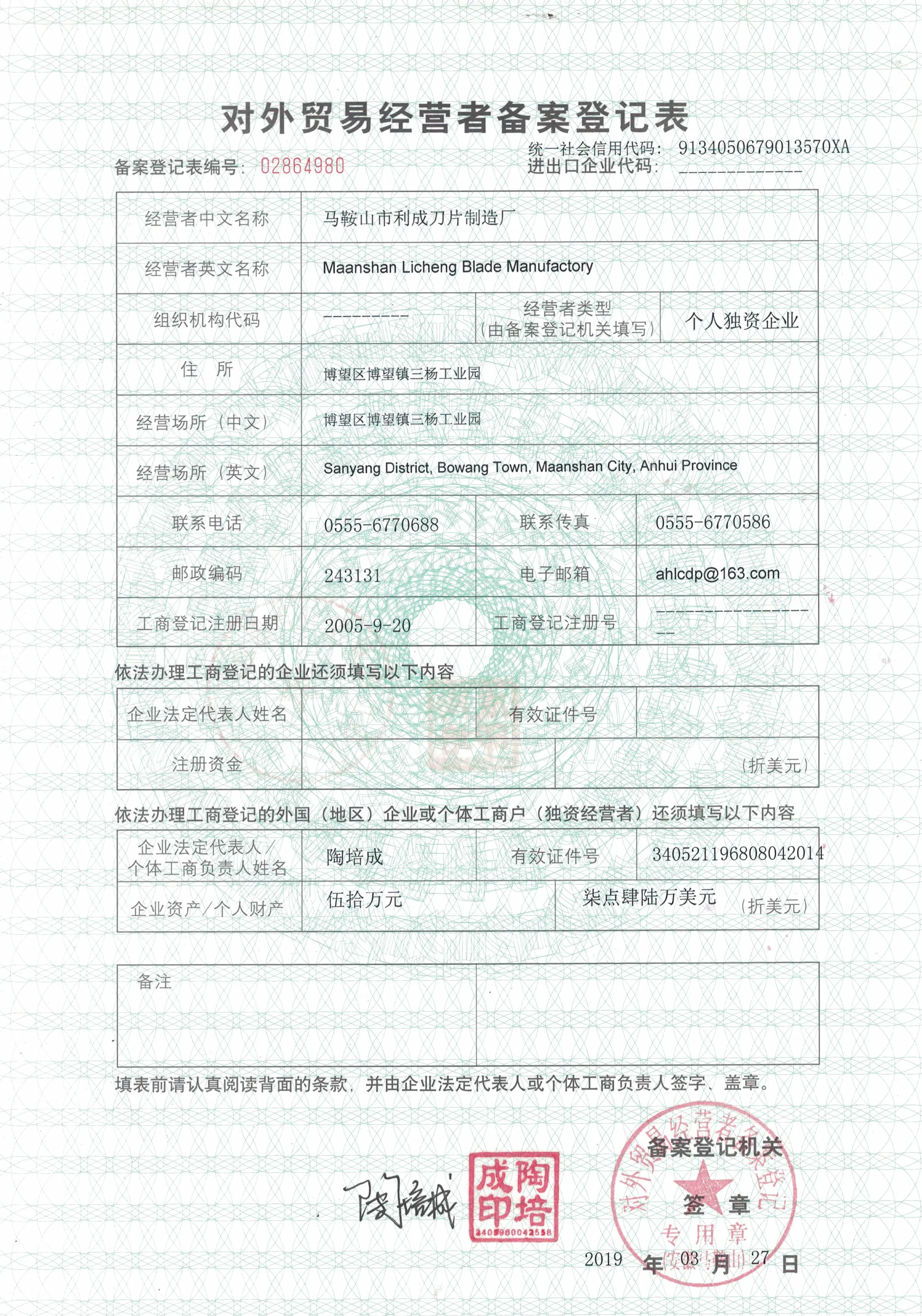

- Поставщик: Nanjing,Licheng,Machinery,Blade,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Brand | LC | ||||||

Material | HSS, M42, TCT | ||||||

Hardness | 62-66HRC; 90HRA | ||||||

Precision | OD±0.05mm, ID0.05-0.08mm usually, Thickness ±0.01mm | ||||||

Roughness | Ra0.2 | ||||||

Certification | ISO9001:2015 | ||||||

OEM Service | Available | ||||||

Applications | Corrugated Paper industry | ||||||

Advantages | 1. Stable quality with super fine grain size and high density 2. Strict tolerance control available for high requirements 3. Excellent wear resistance lasts 5 million meters 4. Superior strength of knife workable for high speed machine | ||||||

Model NO. | Sizes |

Slitter knife 1 | 220*115*1-3*9 |

Slitter knife 2 | 230*110*1.1-6*9 |

Slitter knife 3 | 230*135*1.1 |

Slitter knife 4 | 240*32*1.2-2*8.5 |

Slitter knife 5 | 240*115*1-3*9 |

Slitter knife 6 | 250*150*0.8 |

Slitter knife 7 | 257*135*1.1 |

Slitter knife 8 | 260*140*1.5 |

Slitter knife 9 | 260*168.3*1.2 |

Slitter knife 10 | 280*202*1.4 |

Slitter knife 11 | 291*203*1 |

Company Profile

Manufacturing Technique

Step1 raw materia analysis and choice

Step2 Material forging

Step3 Raw material process

Step4 Material heat treatment

Step5 Product precise manufacturing

Step6 Product inspection

Step7 Product package

Exhibition

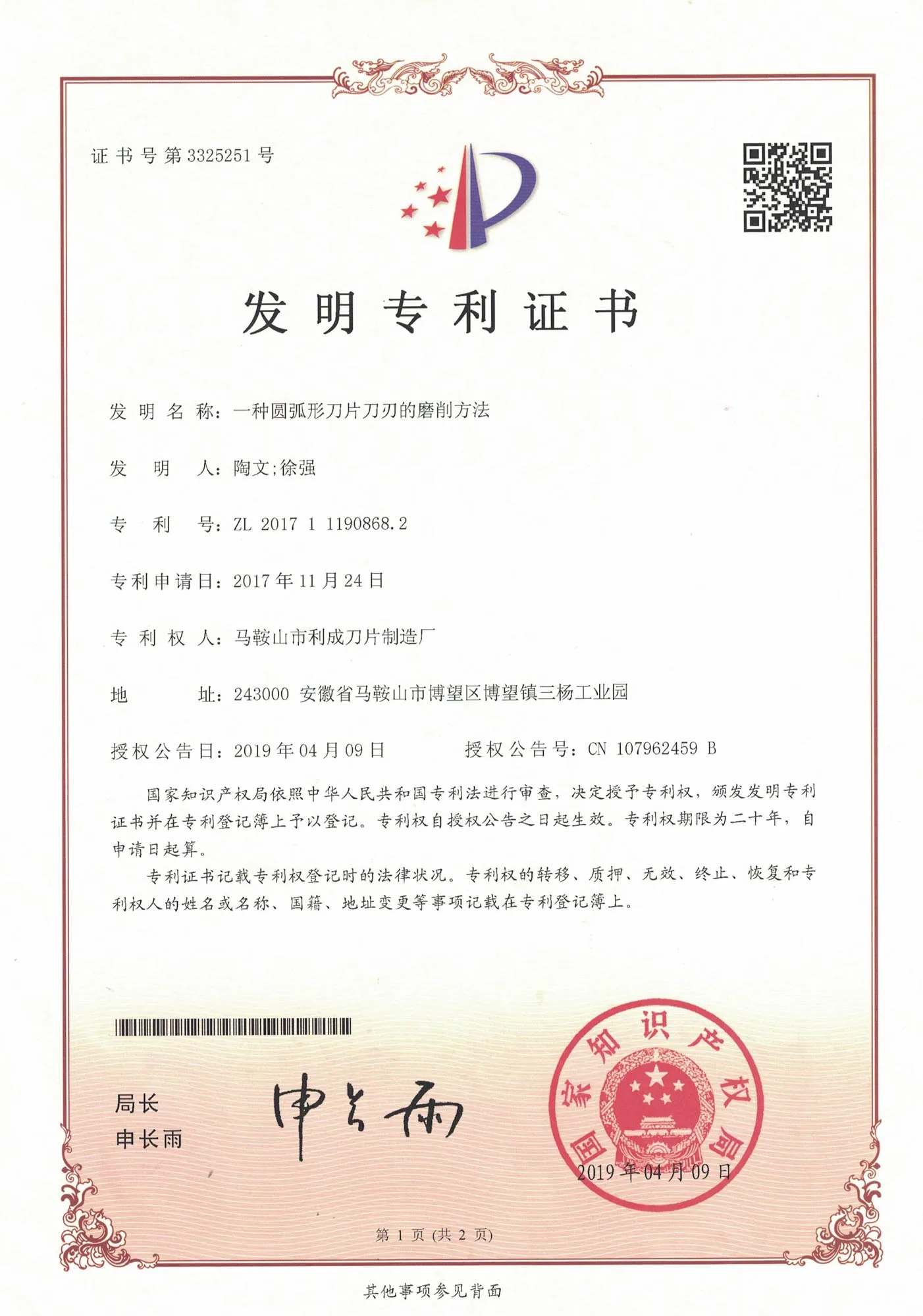

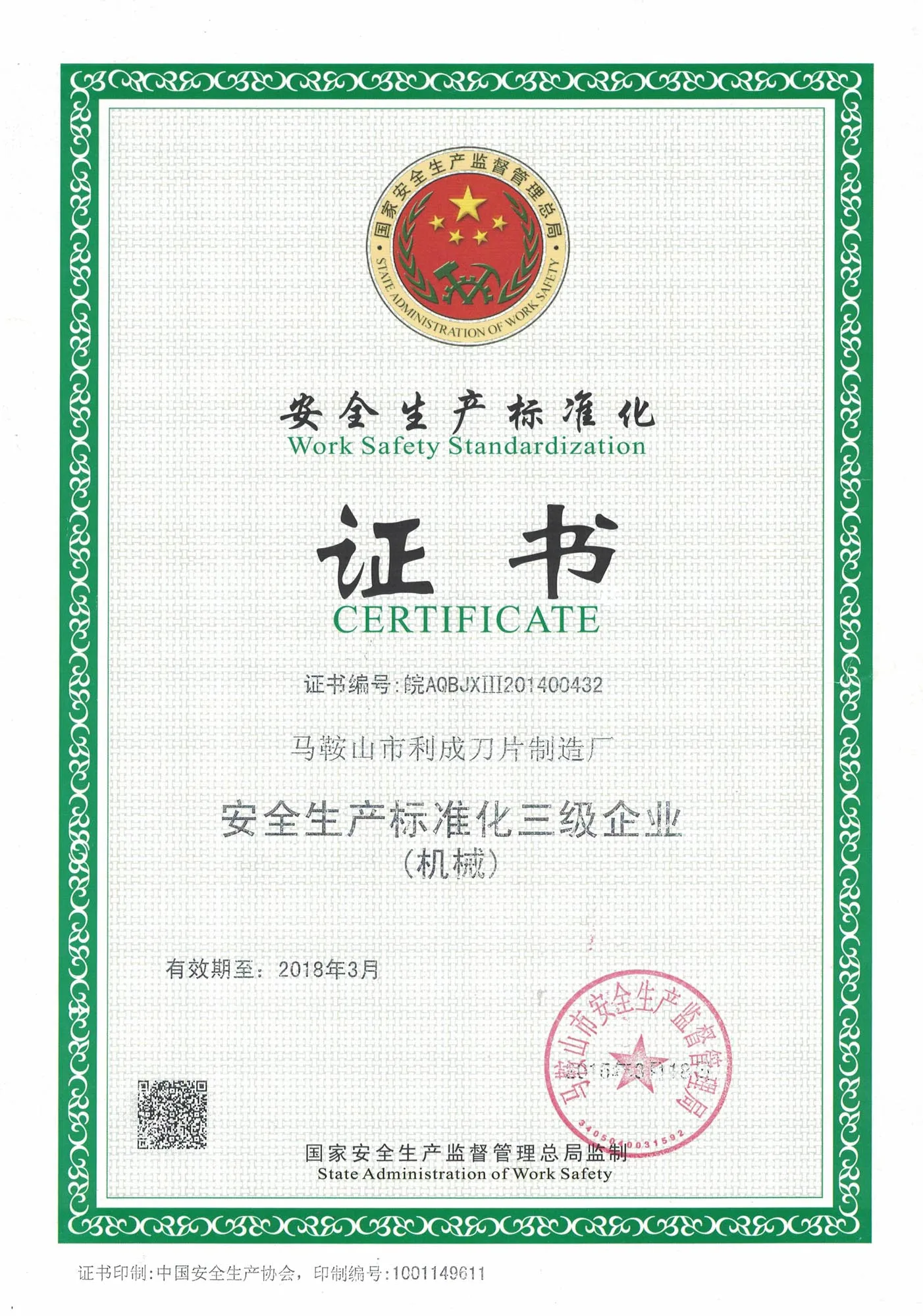

Certifications

Packing&Delivery

FAQ

1.Q: How to extend the life time of the corrugated paper knife?

A: 1. Match a suitable grain size of the grinding wheel.

Too coarse grain size of grinding wheel will shorten the life time of knifes.

2.Reduce the grinding frequency, grinding time and lower the grinding pressure.

Too coarse grain size of grinding wheel will shorten the life time of knifes.

2.Reduce the grinding frequency, grinding time and lower the grinding pressure.

2.Q: Why the edges of corrugated boards cut by knifes with burr and dent?

A: 1.The cutting edge of the blade is not keen enough.

2. The corrugated board is too wet.

A: 1.The cutting edge of the blade is not keen enough.

2. The corrugated board is too wet.

3.Q: Why there are chips on the cutting edge after grinding?

A: 1.Unstable swing grinding wheels may cause this problem, even break the knifes.

2.The strike of hard things may make the chips on the cutting edge.

2.The strike of hard things may make the chips on the cutting edge.