Линия по производству фруктового сока Lemonade с разливочной

- Категории: Pharmaceutical Filling Machine >>>

- Поставщик: Zhangjiagang,Paima,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

This filling machine is mainly designed for filling hot temperature liquid into glass bottle; For example juice, tea drinks etc which are made of concentrate juice. The final filling temperature will be around 85-90 degree centigrade; Once the thermal meter in juice filling machine is lower than the temperature, juice will be return to sterilizing machine again through return system. Glass bottle juice filling machine is different from plastic bottle. It will be optional and suggested to apply 4 in 1 filling machine, one more washing system is adopted to warm up the glass bottle in advance.

The CSD filling machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine tofill various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

Beverage Machinery can finish all the process such as press bottle, filling and sealing, it can reduce the materials and outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

characteristic of juice filling machine

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this nable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Specification

Project | Juice filling machine | ||||||||||

Model | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-15 | |||||

Capacity (BPH) | 2000-3000 | 3000-5000 | 5000-7000 | 7000-10000 | 10000-15000 | 16000-20000 | |||||

Applicable bottle | φ=50-115 H=160-330 (200ML TO 2000ML) plastic screw cup or crown cap | ||||||||||

Air press(Mpa) | ≤0.4 | ||||||||||

Power supply | 4.4 KW | 5.2 KW | 6.2 KW | 6.2 KW | 7.5 KW | 11 KW | |||||

Overall dimension (mm) | 2250×1650×2250 | 2600×1965×2250 | 2980×2200×2250 | 3880×2200×2250 | 4000×2250×2500 | 5500×3500×2500 | |||||

Weight (KG) | 2500 | 3500 | 4500 | 6000 | 7200 | 10000 | |||||

Devices | Brand | Origins |

PLC | SIEMENS | Germany |

Inverter | SIEMENS | Germany |

Touch Screen | SIEMENS | Germany |

Switch | Schneider | France |

Contactor | Schneider | France |

Relayer | Schneider | France |

Solenoid Valve | FESTO | Germany |

Drive Motor | SEW EURODRIVE | Germany |

Reducer | SEW EURODRIVE | Germany |

Water Pump | GRUNDFOS | Denmark |

Main Bearing | SKF | Sweden |

Sensor | SICK | Germany |

Air Component | FESTO | Germany |

Stainless Steel Frame | POSCO | Korea |

Details Images

Washing heads

1.Using unique design,avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the

pollution.

2.Washing pump is made of stainless steel.

3. By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

4. Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance.

Filling heads

1.Filling method for gravity filling.

2.Filling valve manufactured SUS 304/316L.

3.High precision, high speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

Capping heads

1.Automatic check,no bottle no capping.

2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5.High efficiency centrifugal principle.

Features

Main Features of juice filling machines

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Related Products

Automatic Fruit Juice Hot Filling Bottling Production Line

1. Bottle making system

pet preform→Autoloader→reheater →molding→ bottles

2. Water purification system

Source water tank →Source water pump→ Quartz sand filter→ Active carbon filter→ Ion soften machine→ Fine filter →Reverse Osmosis →Ozone sterilizer → pure water tank

3. Juice CSD drink processing system

(1). High-shear emulsifying tank + Plate heat exchanger

(2). Mixing tank

(3). UHT sterilizer + homogenizer machine + Buffer tank

(4). Hot water system + Hot water tank

(5). CIP cleaning system

4. Bottle filling & packing system

Pure water tank→Bottle blower→Air conveyor →Washing, filling & capping 3-in-1→ Light check → Full-automatic labeling machine → Inkjet machine →Full automatic PE film packing machine→ warehouse

Bottle blowing machine

Water Treatment System

Beverage Filling Machine

Hot Melt Glue Labeling Machine

Shrink Sleeve Labeling Machine

Adhesive Sticker Labeling Machine

Shrink Wrapping Machine

Grab Type Carton Packer

One Piece Type Carton Packer

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided for you.

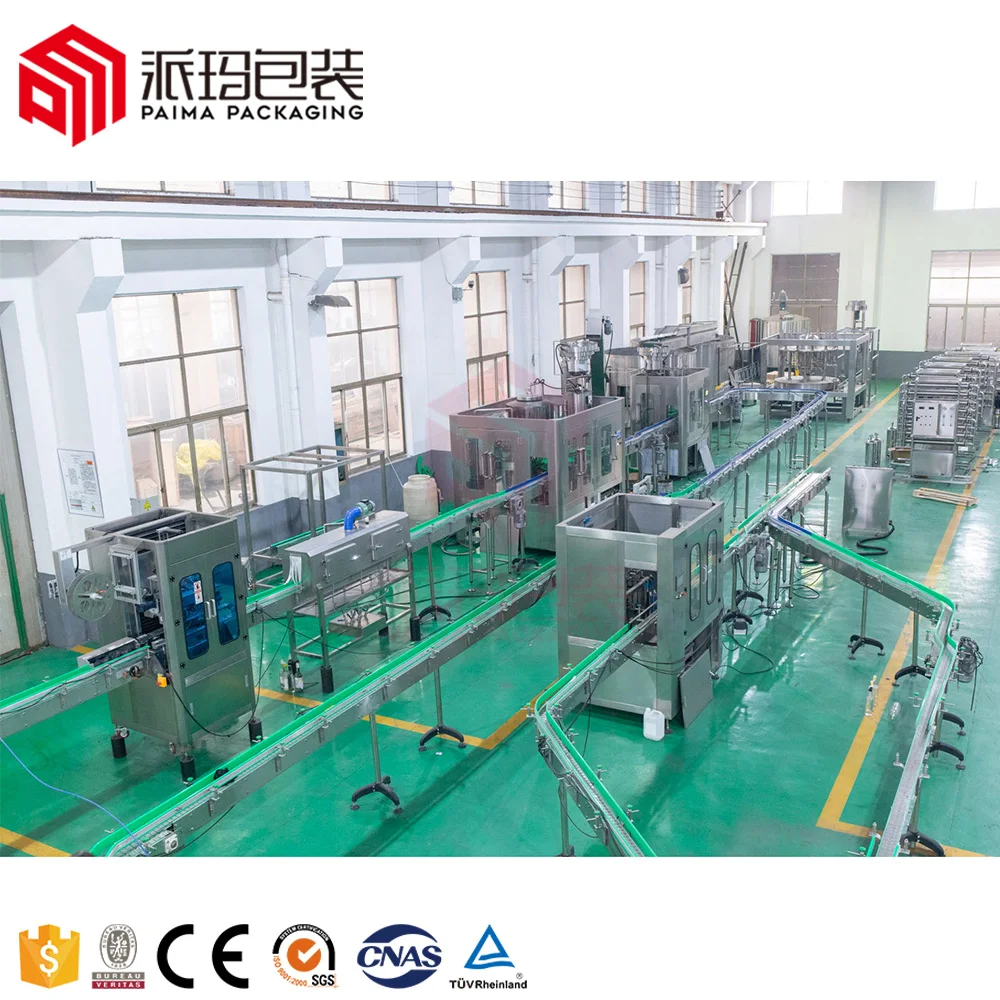

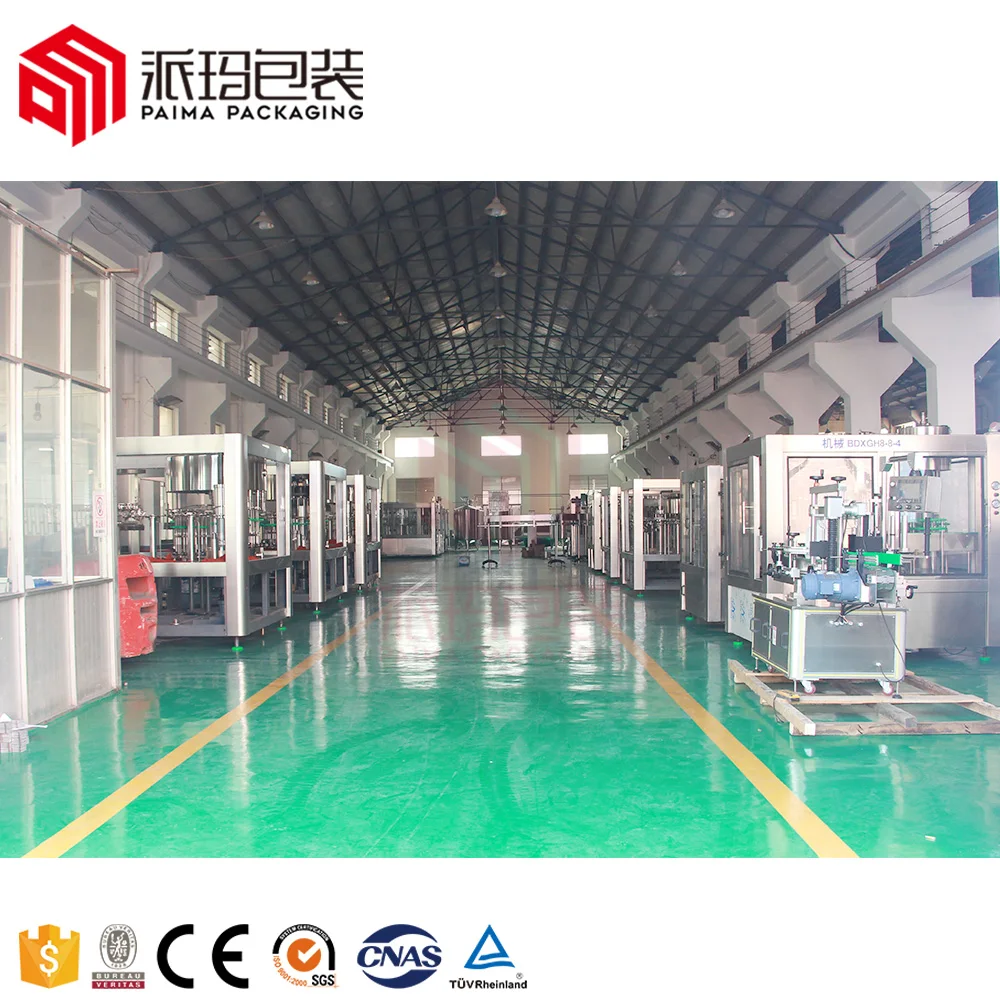

Company Profile

P&M is a professional manufacturer consists of research&design,production and marketing in one unit, It is a professional manufacturer of beverage packaging production line and packing material Since the establishment, we Rely on the ideal " faith and Steadfast,pursue remarkable" we insist on the realistic policy and show the perfect service to our customer,we are always design and update our machine quality based on the ended user's actual use situation,due to our hard working, we help our customer save a lot of labor cost and enhance their market competitiveness.

Due to the advanced technology,the fine processing equipment,we are already popular and reliable to our customer with its machine quality and faith,we welcome the customer from all around the world visit our company,thank you for your trust and help honestly,we believe mutual cooperate and respect mutual benefit and treat the person faithfully,at the end,we will successfully together..

1.HOW TO FIND US?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send us an request and tell your basic inquiry

● Our sales manager will reply you in short time and add instant chatting tool

2.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

3.HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4.HOW TO ENSURE THE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

5.THE AFTER-SALE SERVICE OF PAIMA MACHINE?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Похожие товары

Автоматическая машина для розлива комаров

US $28000-$35000

Автоматическая линия по производству разливных бутылок для жидких ампул

US $250000-$300000

Целлофановая машина для обертывания BOPP Cellowrap

US $1800-$2000