От ведущего производителя качественной продукции фосфор медь сварочная проволока/стержень цветных металлов BCuP-5 CP102

- Категории: Welding & Soldering Supplies >>>

- Поставщик: Ningbo,Feihong,Alloy,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

The Phosphorus Copper filer alloys are extensively used to join copper and copper alloy base metals (brass, bronzes). Phos-Copper is extensively used in Non-Ferrous Industry. They have self-fluxing properties when used on copper and may or may not contain Silver. Continuous service operating temperatures of joints brazed with these alloys range up to approx 200 °C.

Corrosion resistance is satisfactory, except when the joints are exposed to sulfurous environments, especially at elevated temperatures.

Phosphorous Copper alloys should not be used on ferrous, nickel based alloys, or copper-nickel alloys with more of 10% nickel, in order to avoid premature failure of the joint due to the formation of brittle intermetallic phases.

| Chenical Composition % | Solidus | Liquidus | |||

| Product Sizes information | |

| Rods: | φ1.6-5.0mm |

| Length: 200-1000mm | 200-1000mm |

| Spools and Coils | |

| Coated rods: | φ1.6-4.8mm |

| Length: | 200-1000mm |

| Strips Thickness:: | 0.2-1.0mm |

| Width: | 1.3-100mm |

| Rings Min. inner diameter: | 2.5mm available layers ring |

| Buttons and Sheet: | Available |

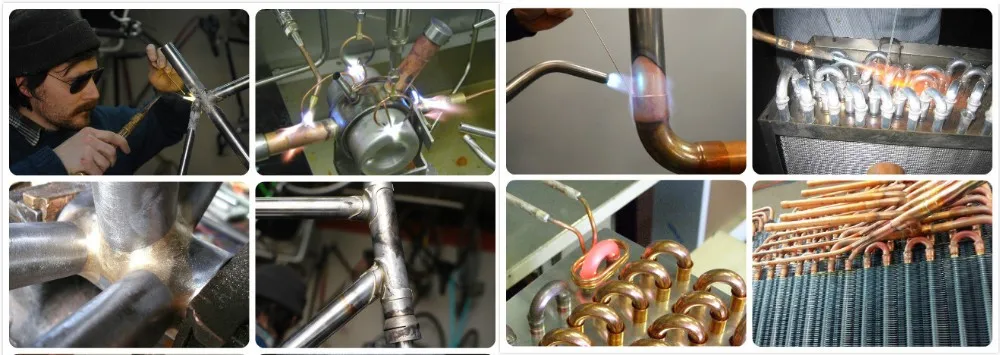

| Application |

![]()

Our Service

| Ningbo Feihong Alloy Material Co., Ltd. was founded in 1986, which is a hi-tech enterprise devoted to the research, manufacture and sales of new series of non-ferrous alloy materials. Our company has achieved the ISO9001 quality management system and ISO14001 environmental management system certification. The products are widely used in aviation, aerospace, high-speed rail, automobiles, ships, electric power, motors, refrigeration, handicrafts, heat exchange and more than 30 fields. |

![]()

|

Q: How long can I receive your reply after I send my inquiry? A: We will reply you within 12 hours on workday.

Q: Are you a manufacturer or a trade company? A: We have a complete alloy materials production line including smelting, extruding, drawing and heat treating. At the same time, we have our own international trade department, we market our own products.

Q: What products can you provide? A: We specialize in producing non-ferrous alloy materials products.

Q: What are the application fields of your products? A: Our products are widely used in aviation, aerospace, high-speed rail, automobiles, ships, electric power, motors, refrigeration, handicrafts, heat exchange and more than 30 fields.

Q: Can you provide custom products? A: Yes, we can develop and manufacture products according to customer sample.

Q: Where do you mainly export your products? A: Our products are mainly exported to more than 20 countries, including Europe and the United States, the Middle East, Southeast Asia and Africa.

Q: What’s your delivery method? A: We commonly use sea transportation, because we are only 50km away from Ningbo port, the sea transportation is convenient. Of course, we can also use air transportation, we are only 60km away from Ningbo airport.

Q: Payment? A: We will confirm the payment with you when quoting, like FOB, CIF, CNF or others. In batch production, we accept 30% deposit, balance against the copy of B/L. T/T is the main payment, and L/C is acceptable as well.

Q: How can you ensure your product quality? A: We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer’s requirements. We have advanced inspection equipments, including spectrometer, metallographic microscope, universal tensile testing machine, ultrasonic flaw detector etc. The above equipment can ensure the high-precision of the finished products, and meet customer’s inspection requirement in the aspects of physical and chemical properties, non-destructive testing, high-precision geometric size testing.

Q: How many employees do you have? A: We have over 100 employees, including 10 technicians and 10 engineers.

Q: How’s your production capacity? A: We have 6 alloy material production line. The daily output is over 60 tons. |