Описание и отзывы

Характеристики

ArcFeeder IV Voltage-sensingWire Feeder

The voltage-sensing wire feeder uses the welding voltage to generate the energy required for controlling the wire feeder's operation. Before welding, you just select the desired settings for the feeder and the power source according to the welding requirements, the base materials, filler materials, and the shielding gas.

When you start welding in CC, parameters can be controlled by the feeder in order to ensure the high welding quality.

For normal MIG/MAG welding, the parameters' values are controlled by the power source via the control cable, but voltage-sensing technology makes such a control cable between the power source and the feeder unnecessary.

Constant Current (CC) power source

The CC type of welding machine can change the wire feeding speed according to the arc voltage.

The voltage will change with different arc lengths but with slight change for current.

Constant Voltage (CV) power source

The CV type of welding machine can maintain a relatively stable, consistent voltage regardless of the change for current. It results in a relatively flat volt-amp curve. The MIG/MAG welding machines are typically CV type machines.

Technical Parameters:

Model | Suitcase | Dimension(LxWxH) | 590x220x370mm |

Input Power | DC15-105V | Net Weight | 12.5kg |

Diameter | Flux-Cored:1.0-2.0mm Gas and Inner-shielded: 1.6-2.0mm (2.4mm) Solid-Cored: 0.8-1.6mm | Rate Output | 400A 100% |

Spool Size | Φ300mm | Protection Index | IP23 |

Speed | 0-25m/min | Insulation Class | H |

Advanced Features:

- Voltage sensing technical wire feeder;

- Fully-enclosed molded composite metal-plastic case;

- Easy operation, easy connection with power source;

- Capable of Flux cord, Solid wire and Inner-shielded wire welding;

- No need special control cable between the power source and wire feeder;

- Suitable for CC/CV power source;

- 4-roll print motor with PWM drive;

- Excellent arc ignition

- Good reliability

- Automatically suit the change of welding polarity.

- Suitable for most DC power source

- Scale/Digital Meter/LCD show parameter separately

Application Range:

● Sort of base metal:Various steel.

● Thickness of base metal:≥ 2mm

● Wire diameter(mm):Flux-cored welding wire Ф1.2~Ф2.0 or max. 2.4mm

Innershield welding wire Ф1.6~Ф2.0 or max. 2.4mm

Solid welding wire Ф1.0~Ф1.6mm

Standard Configuration:

- ArcFeeder 1 Unit

- Arc Voltage Sensing Lines\t1 Piece (3m with sampling clamp)

Optional Configurations:

1. Welding torch

2. Cable

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

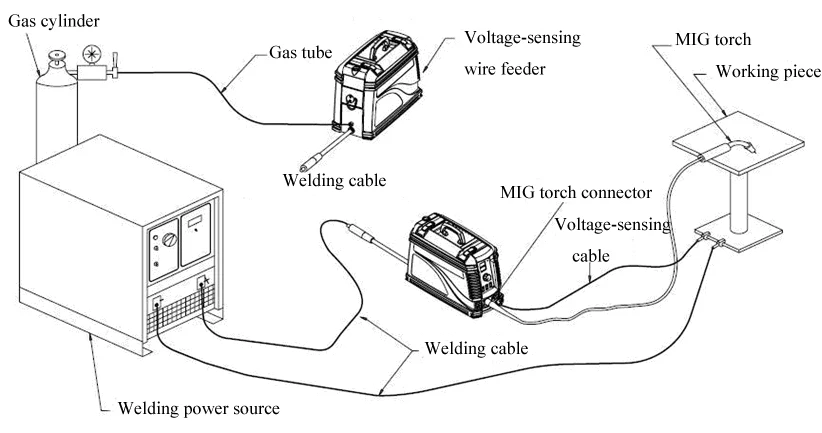

ArcFeeder System Connection Diagram:

AreFeeder Sketch:

1. TORCH SOCKET:EURO style(standard outfit) PANASONIC OR other.(optional )

2. VSLEAD:voltage sensing lead,used for connecting voltage sensing cable.

3. WFS (Wire feeding speed): Used for adjusting welding wire speed, corresponding to welding current, wire diameter and welding materials.

4. WFS display:used for wire feeding speed display,unit:mpm.

5. POLARITY indicator:When DCEN is valuable, POLARITY indicator is lighting.

6. POWER indicator:When power is on, POWER indicator is lighting.

7. WELDING CONNECTOR:used for connecting welding cable.

8. Inlet: Used for connect shielded gas tube.

9. Purge: Used to test the shielding gas and measure the gas flow. If presses down this switch, there is no electricity in wire.

10. GAS regulator:used for protection gas regulating,unit:LPM.

11. TORCH HOLD:used for torchhold selection,when "1",torchhold is valuable.

12. POWER switch: Used for turning ON/OFF the power in wire feeder. Please turn OFF the feeder when it is not in use.

13. CC/CV selection mode: Used for selecting working mode of wire feeder. Set this switch according to the power source you are using.

14. Inch: Used to drive the welding wire before welding. If presses it down, there is also no electricity in wire.

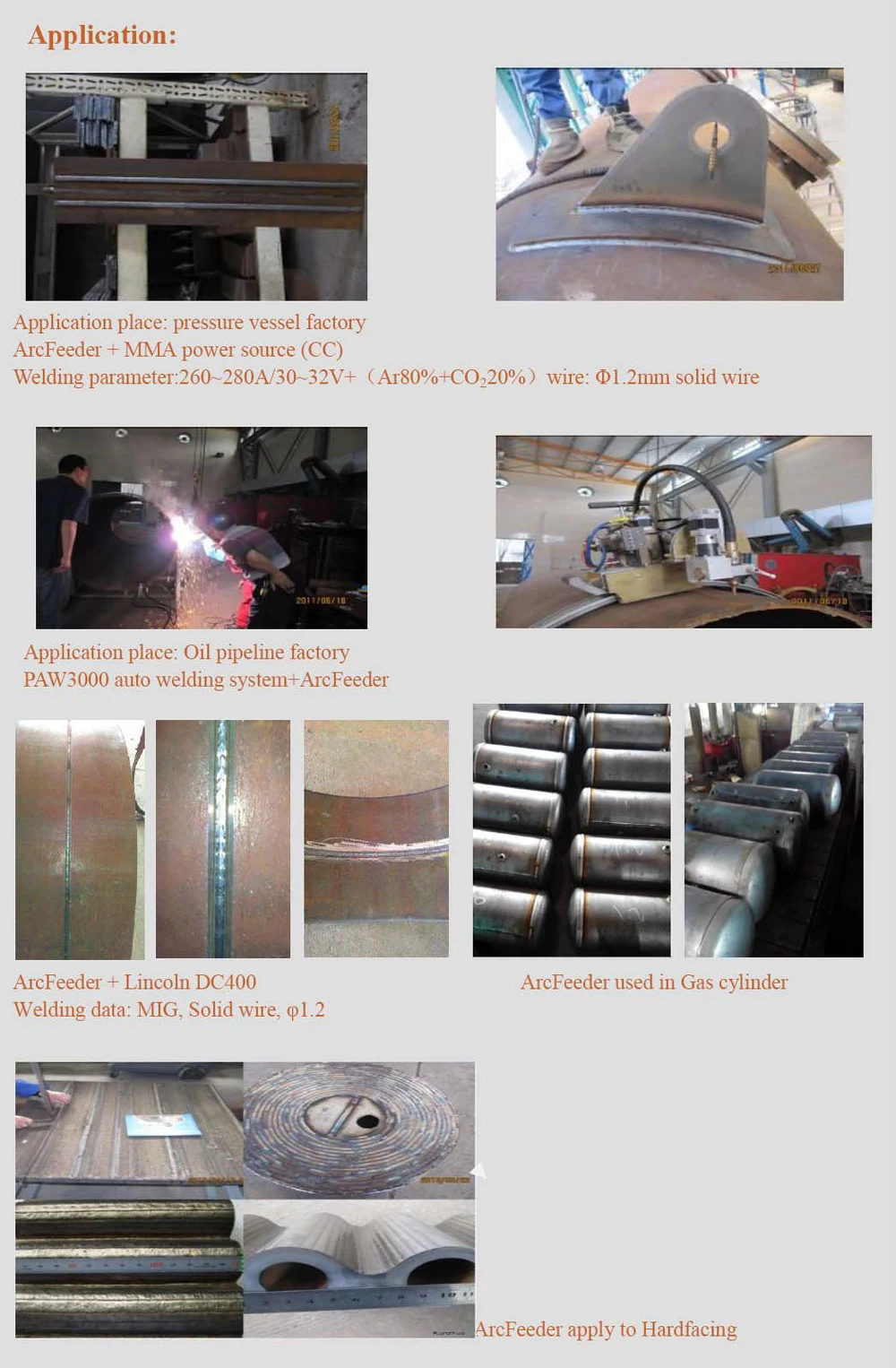

Welding of vehicle axle by matching KR350, achieving low spatter and high-speed welding; welding conditions: φ1.2 solid wire, mixed gas(Ar80%+CO220%) and 260A~280A/30~32V; welding speed: 1.5m/min:

Welding of pressure vessels by matching common MMA; welding conditions: φ1.2 solid wire, mixed gas (Ar80%+CO220%) and 260A~280A/30~32V:

Related Products: