Китайский композитный Железнодорожный тормозной блок

- Категории: Train Parts & Accessories >>>

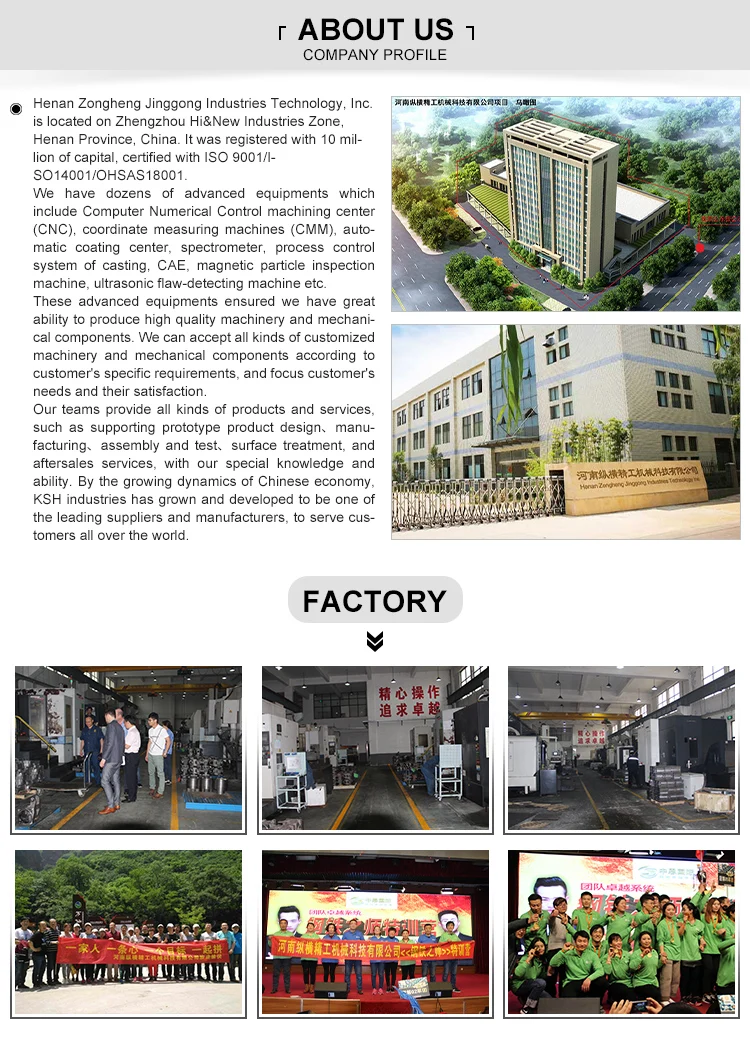

- Поставщик: Henan,Zongheng,Precision,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

| Brand | KSH |

| Name | Railway Brake |

| Applications | Automobile,petroleum drilling machine; |

| Locomotive Parts for Passenger train or Cargo train. | |

| Material | Composite |

| Braking Force | High friction |

| Service LIfe | >12,000km |

| (Note: it must be replaced after 12,000 Km) | |

| Surface Treatment | 1. Plain oiled |

| 2. Painting |

Casting Service:

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

KSH offers multiple investment casting, sand casting, permanent casting, die casting, low pressure casting, ESR casting, lost foam casting, etc. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 150 tons separately.

KSH has 20+ years experence and focus on the following area:

Locomitive

Construction Machinery

Valve and pumps

Other general equipment

KSH can be made and designed as customers drawings or samples.

If you are interesting in any of our products,pls do not hesitate to contact with us!

Process Quality Control

1,Make proper designing of mould precisely to ensure dimensions of product qualified.

2,Strictly control the production temperature to ensure well-distributed temperature.

3,Inspect dimensions of product and surface quality at regular