MTW горячая Распродажа духов и запаек цифровая маленькая дитроновая жидкость для машины розлива электронных

- Категории: Tobacco & Cigarette Machinery >>>

- Поставщик: Tianjin,Maitewei,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Introduction:

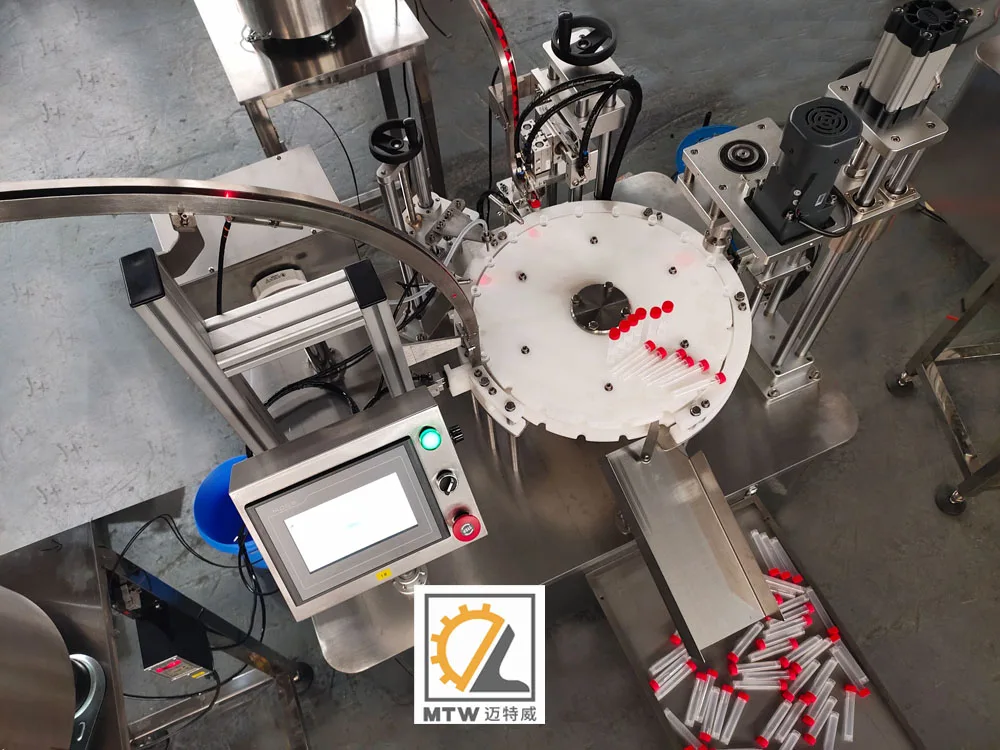

This is a monoblock filling and capping machine (filling and capping machine together). All stations are working on a star wheel, which is suitable for small volume bottles. It is commonly used in tube, reagent testing tube, eye drop, e liquid, essential oil biologics liquid and some other small bottles and vials liquid filling inner cap pressing and outter cap closing in pharmaceutical and other industrial.

Parameters:

Item | 1 filling head & 1 capping head | 2 filling heads & 1 capping head |

Filling range | 1-30ml (30-100ml also ok) | |

Cap type | All kinds screw caps/ press cap/ aluminum cap | |

Filling method | Peristaltic pump | |

Filling speed | About 3000 bottles/ hour | |

Filling precision | ±0.5-1% | |

Yied of capping | ≥99% | |

Power | 220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries) | |

Air pressure | 0.6-0.8Mpa | |

Weight | 450Kg | 500kg |

Machine side | 2000*1500*1700 (L*W*Hmm) | 2000*1500*1700 (L*W*Hmm) |

Features:

Using the peristaltic or piston pump to fill, use good for small volume, with high accuracy, meet GMP standard.

It is easy to adjust the degree of tightness of the magnetic moment cap screwing head;

Machine component: The machine use world word-class brand components:

Sensor--- Sick (Germany) PLC---Mitsubishi (Japan) Electronic control part--- Mitsubishi (Japan) Touch screen---MCGS (Beijing) Cylinder--AirAc (Taiwan)

Controlling system:

The machine adopts full-auto PLC + human-computer touch screen control system. For different volumes for example, 1ml, 10ml, 20ml, we set three procedures, mode 1, mode 2, model 3``` The PLC can save these parameters for later use.

Bottle position correct device:

To ensure the bottles and filling heads are in the correct position, we add star wheel to fix bottles, and make the whole filling & capping process smooth and stable. No bottle no filling.

Filling heads: The filling heads are specially made, with the function of anti-drop and anti-drawing, without bubble.

Cleaning: The pump uses quick-fit removal Structure: easy cleaning and disinfection. Can link with CIP cleaning system.

PACKAGE:

Standard export wooden case packing.

DELIVERY TIME:

30-40 days after confirming order,detail delivery date should be decided according to

production season and order quantity.