W12nc-arc вниз с регулируемой четырех-н-ролл накатный станок для сгибания пластин Металла листопрокатного производства оборудование формования валковая гибочная машина по

- Категории: Plate Bending Rolls >>>

- Поставщик: Nantong,Pacific,CNC,Machine,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Main structural features

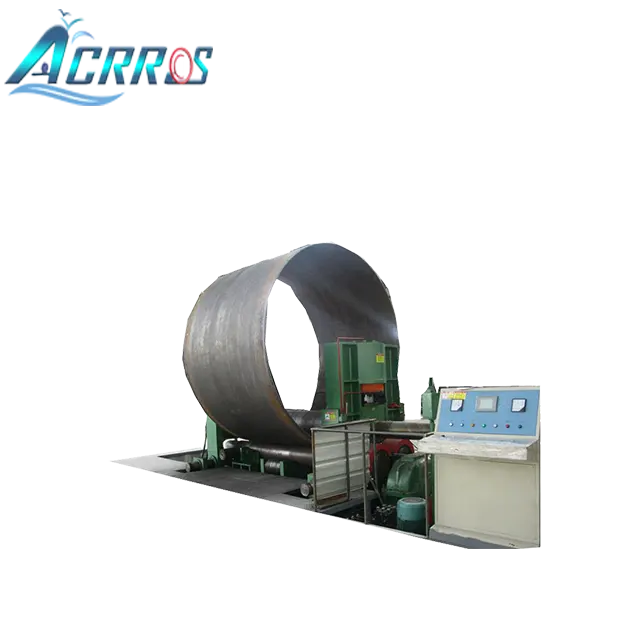

W12NC-series arc lower adjustment four-roll plate bending machine, which can feed metal sheet at one time, and can complete

pre-bending and rolling forming of sheet end without turning head. The remaining straight edge is small, which is an ideal

equipment for rolling round and arc workpieces.

The working roller on the machine is mainly driven by hydraulic motor and Reducer: the lower roller can be driven by auxiliary

motor or passive roller. The side roller is passive roller, the lower roller and the side roller are hydraulic transmission, the

lifting displacement is controlled by PLC, automatic leveling, the screen digital display, the synchronization accuracy ± 0.15mm.

The lower roller makes vertical lifting movement so as to clamp the plate; Side rollers are arranged on both sides of the lower

roller and arc lifting movement can be driven by hydraulic cylinder.

The flip and reset of the flip bearing body is driven by hydraulic pressure, and the tail of the upper roller is equipped with

balancer, which can easily discharge the rolled workpiece and cylinder. It is equipped with mobile independent operating table,

which is convenient for workers to use, and is equipped with safety interlocking device. The machine has full functions, high

precision and convenient operation. It is petroleum, chemical industry, boiler, shipbuilding, hydropower, the most ideal preferred

model for rolling round, curved and tapered workpieces in industries such as metal structure

W12NC-series arc lower adjustment four-roll plate bending machine, which can feed metal sheet at one time, and can complete

pre-bending and rolling forming of sheet end without turning head. The remaining straight edge is small, which is an ideal

equipment for rolling round and arc workpieces.

The working roller on the machine is mainly driven by hydraulic motor and Reducer: the lower roller can be driven by auxiliary

motor or passive roller. The side roller is passive roller, the lower roller and the side roller are hydraulic transmission, the

lifting displacement is controlled by PLC, automatic leveling, the screen digital display, the synchronization accuracy ± 0.15mm.

The lower roller makes vertical lifting movement so as to clamp the plate; Side rollers are arranged on both sides of the lower

roller and arc lifting movement can be driven by hydraulic cylinder.

The flip and reset of the flip bearing body is driven by hydraulic pressure, and the tail of the upper roller is equipped with

balancer, which can easily discharge the rolled workpiece and cylinder. It is equipped with mobile independent operating table,

which is convenient for workers to use, and is equipped with safety interlocking device. The machine has full functions, high

precision and convenient operation. It is petroleum, chemical industry, boiler, shipbuilding, hydropower, the most ideal preferred

model for rolling round, curved and tapered workpieces in industries such as metal structure

42CrMo material Hardened rolls

The top roller is designed asdrum shape. Support rollerinstall in the lower of bottomroler to help bending a perfectcylinder from thin to thick plate.

Main motor

Main electronic:elements:Siemens made in Germany.

PLC control system

PLC control system ensure the machine's bottom and lateral rolls operate synchro-nously. Up to eight steps can be programmed with the

touchscreen.

touchscreen.

Hydraulic system

Bosch-Rexrothmade in Germany

Release device

It's easy for release thefinished workpiece

Main power

Siemens Electricalmade in Germany

Model | Max. Rolling thickness(mm) | Max. crimp width(mm) | Top roller diameter(mm) | Side roller diameter(mm) | Main power |

W12-4X1500 | 4 | 1500 | 140 | 120 | 2.2 |

W12-6X2000 | 6 | 2000 | 190 | 170 | 3 |

W12-6X2500 | 6 | 2500 | 190 | 170 | 3 |

W12-8X2500 | 8 | 2500 | 210 | 190 | 7.5 |

W12-12X2000 | 12 | 2000 | 270 | 250 | 11 |

W12-12X3000 | 12 | 3000 | 300 | 270 | 11 |

W12-16X2500 | 16 | 2500 | 300 | 270 | 15 |

W12-16X4000 | 16 | 4000 | 390 | 360 | 18 |

W12-20X2000 | 20 | 2000 | 330 | 300 | 11 |

W12-20X3000 | 20 | 3000 | 360 | 330 | 15 |

W12-25X2500 | 25 | 2500 | 390 | 360 | 18.5 |

W12-30X2500 | 30 | 2500 | 390 | 360 | 18.5 |

W12-30X3000 | 30 | 3000 | 430 | 390 | 22 |

W12-35X3000 | 35 | 3000 | 460 | 420 | 30 |

W12-45X2500 | 45 | 2500 | 460 | 420 | 30 |

W12-50X2500 | 50 | 2500 | 510 | 460 | 45 |

W12-65X3000 | 65 | 3000 | 650 | 550 | 55 |

Q1. How about the quality of your machines?

Our company is the key backbone enterprise of the national machinery industry, with a group of experienced professional engineering and technical personnel, production and testing equipment, with 20 years of product manufacturing experience.We are committed to customer satisfaction is our pursuit, quality must make customers satisfied.

Q2. Can you give me a better price for the machine?

1.The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

2.We will definitely provide quality = price, price = quality, and the matching price is acceptable to the customer.We welcome you to negotiate with us and obtain good satisfaction.

3.As a factory, we have an advantage in price.

Q3. How can we provide you efficient services (metal processing solution)?

There are Three Steps as following:

Our company is the key backbone enterprise of the national machinery industry, with a group of experienced professional engineering and technical personnel, production and testing equipment, with 20 years of product manufacturing experience.We are committed to customer satisfaction is our pursuit, quality must make customers satisfied.

Q2. Can you give me a better price for the machine?

1.The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

2.We will definitely provide quality = price, price = quality, and the matching price is acceptable to the customer.We welcome you to negotiate with us and obtain good satisfaction.

3.As a factory, we have an advantage in price.

Q3. How can we provide you efficient services (metal processing solution)?

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional

recommendations ;reg. non-standard products, we can offer professional designing.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional

recommendations ;reg. non-standard products, we can offer professional designing.

Похожие товары

TTMC 12 дюймов ручные ножницы Тормозная ролл машина

US $315.00-$429.00

3 ролика листопрокатного машины/чпу роликовый гибочный станок

US $4000-$35000