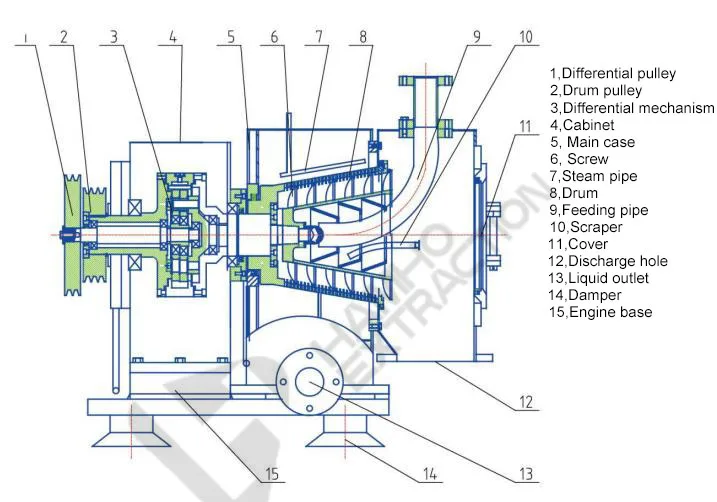

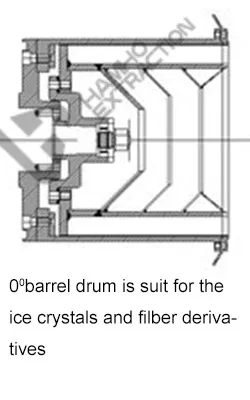

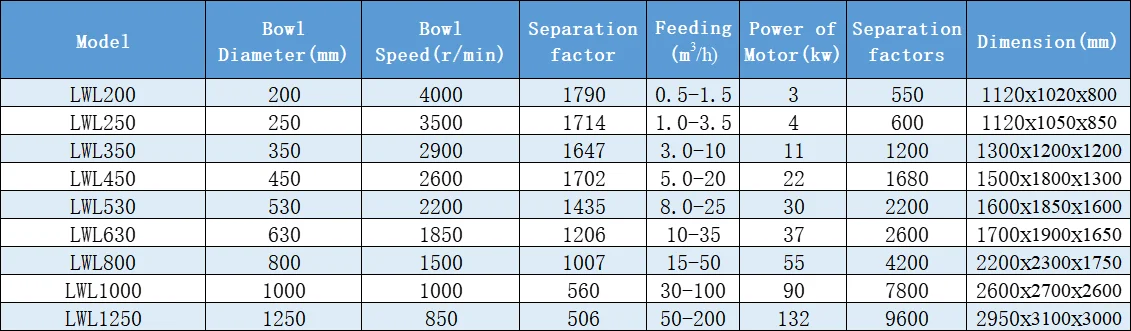

Q: What kind of products do you have?A: Industrial centrifuges like screen scroll centrifuges(LWL), decanter centrifuges(LW), pusher centrifuges(HR), peeler centrifuges, top discharge centrifuges, etc.

Q: How do you control the quality?

A: To ensure the accuracy of each part, we are equipped with a variety of professional equipment, and we have accumulated professional processing methods over the past years.

Each component before assembly needs strict control by inspecting personnel.

After all the equipment is completed, we will conduct a trial run before shipment to ensure the customers' workshop's stable running.

Q: What terms of payment does your company accept

A: Most payment methods are accepted, however, we mainly accept T/T, L/C at sight

Q: How long is your warranty period?

A: Our officially promised warranty time is 12 months after machine's commissioning.

Q: The after-sale service of Hemho

A: After finishing the production, we will test the machine, take photos, videos and send them to customers via email or other instant messenger.

After the commissioning in our factory, we will package the equipment by standard export package for shipment.

Engineers, sales managers and after-sales service manager will form a aflter-sale team, to follow the customers' projects.