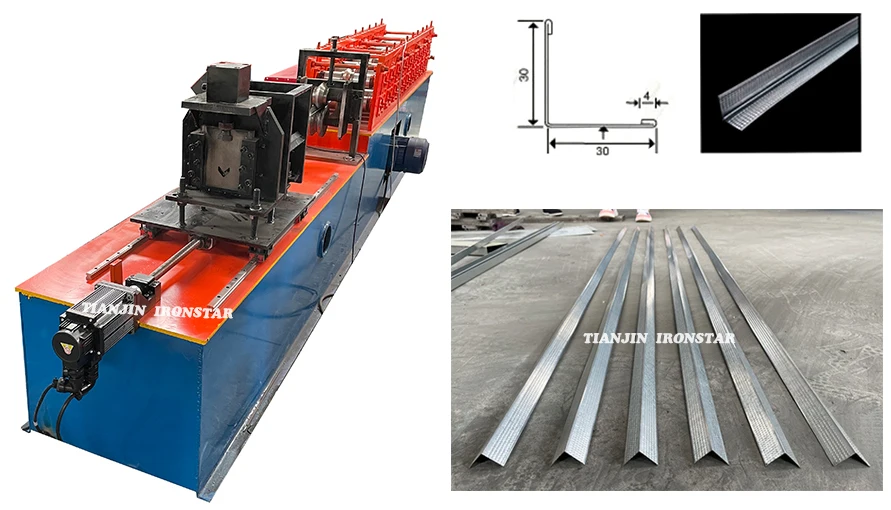

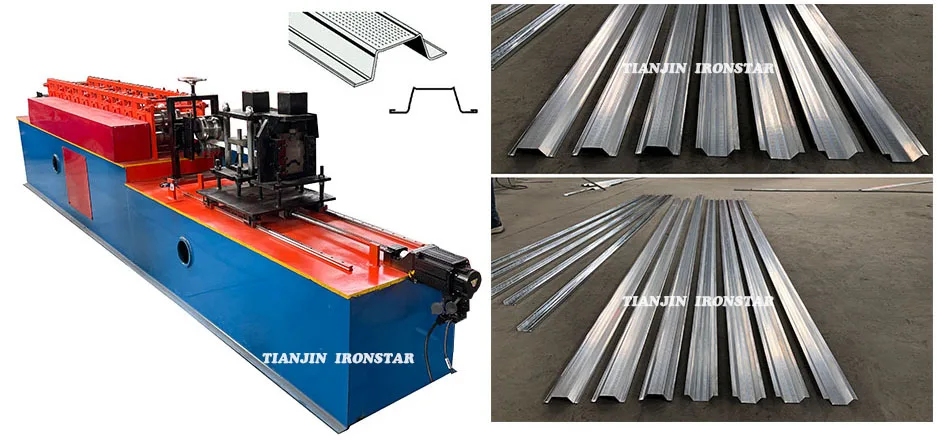

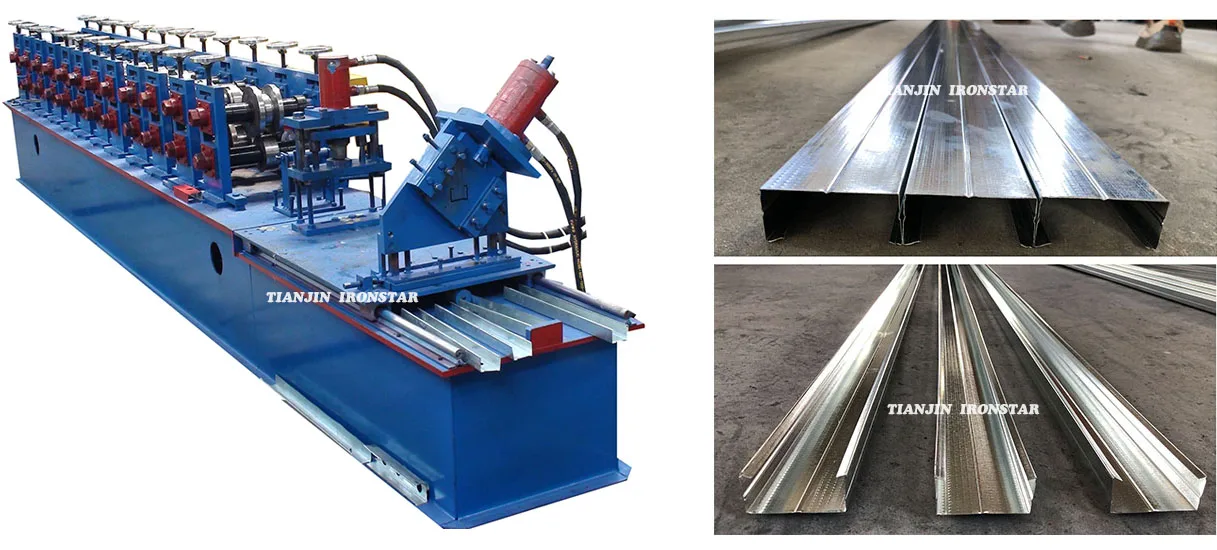

Машина для прокатки листового металла

US $10000

Поделиться:

NO. | Item | Specification |

Material | Raw material | Galvanized steel |

Thickness | 0.3-0.8 mm | |

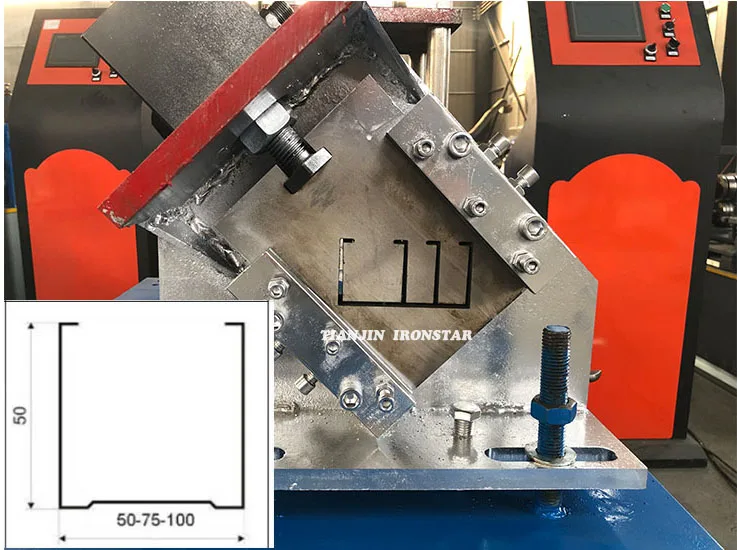

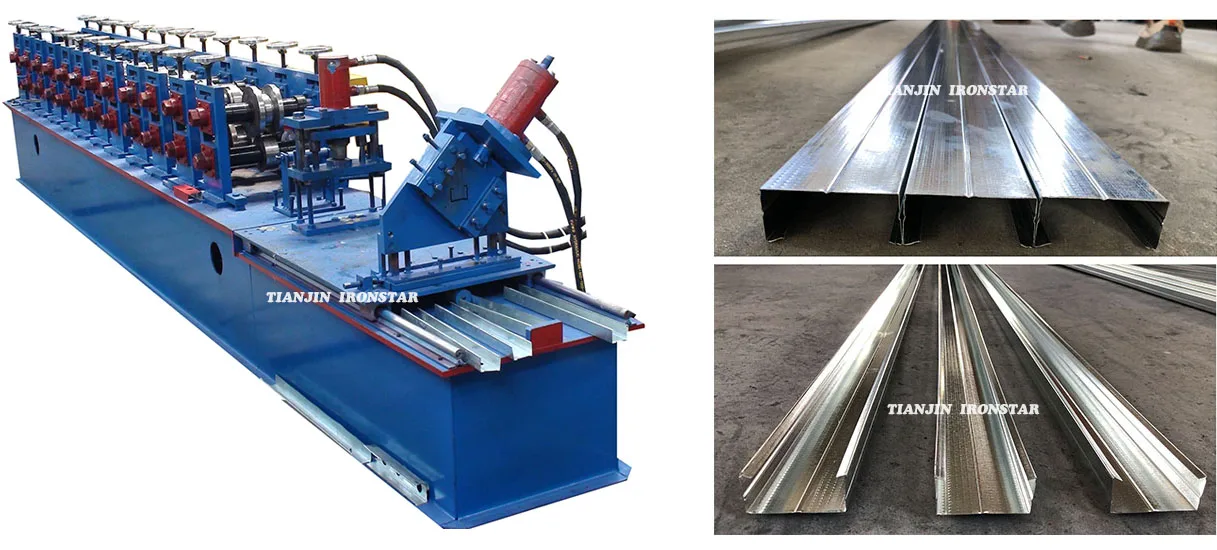

Machine | Roller station | 12 |

Shaft diameter | 55 mm | |

Solid shaft material | High grade 45# steel with Cr12 mov coated, quenching & tempering & treatment | |

Roller material hardness 30-40 HRC | Cr12 | |

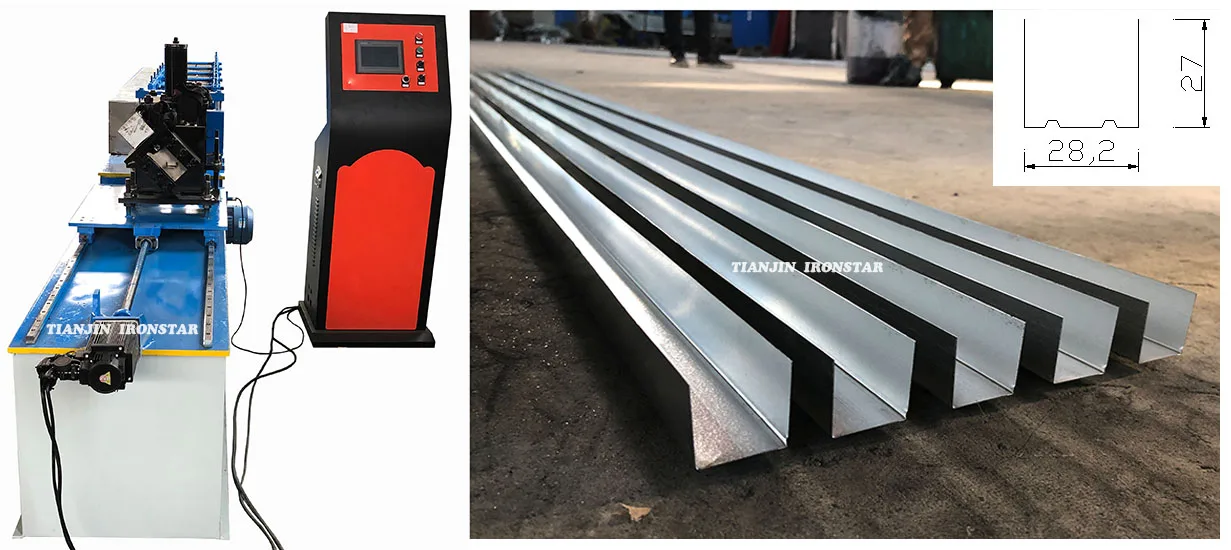

Machine size | About 4.2*0.8*1 m | |

Machine weight | About 1.5 tons | |

Machine color | As customer need | |

Working speed | 30-50 m/min | |

Cutter | Hardness | 50-65 HRC |

Cutting tolerance | ± 1mm | |

Material | Cr12 | |

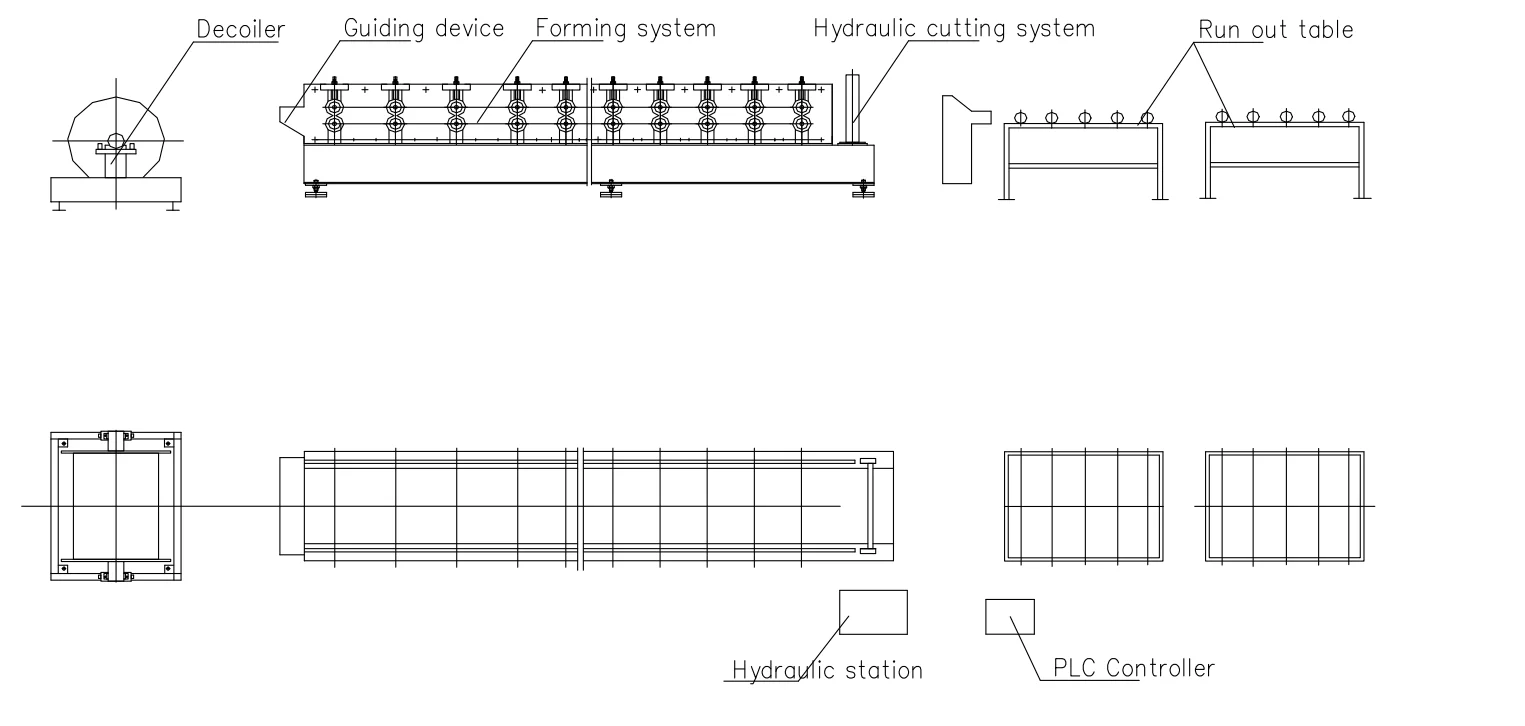

Operate | Hydraulic cutting | |

Power | Driving way | Chain 1 inch |

Main motor | 4 KW | |

Pump motor for cutter | 3 KW | |

Voltage | 380V/50HZ, 3P or Customized as customer' request | |

PLC brand | Delta made in Taiwan | |

Screen | Touchable screen | |

Language | Chinese and English or add customer need language | |

Operation | Manual | |

Weight capacity | 3 Tons | |

Price | Free as gift | |

Receive table | Operation | Manual |

Length | 3 m | |

Price | Free as gift |