Одностворчатая дверь 50 мм стандарт GMP порошковое покрытие с панелью просмотра для чистой

- Категории: Other Air Cleaning Equipment >>>

- Поставщик: Suzhou,Lucky,International,Import,&,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Clean Room Turnkey Project .

Clean Room System:

1. Construction work: wall panels, ceiling panels, flush mounted doors and windows, interlocks for doors in the clean room environment.

2.HVAC system : AHU & Chiller system

3.Clean room Euquipment.

1. Construction work: wall panels, ceiling panels, flush mounted doors and windows, interlocks for doors in the clean room environment.

2.HVAC system : AHU & Chiller system

3.Clean room Euquipment.

Detailed Images

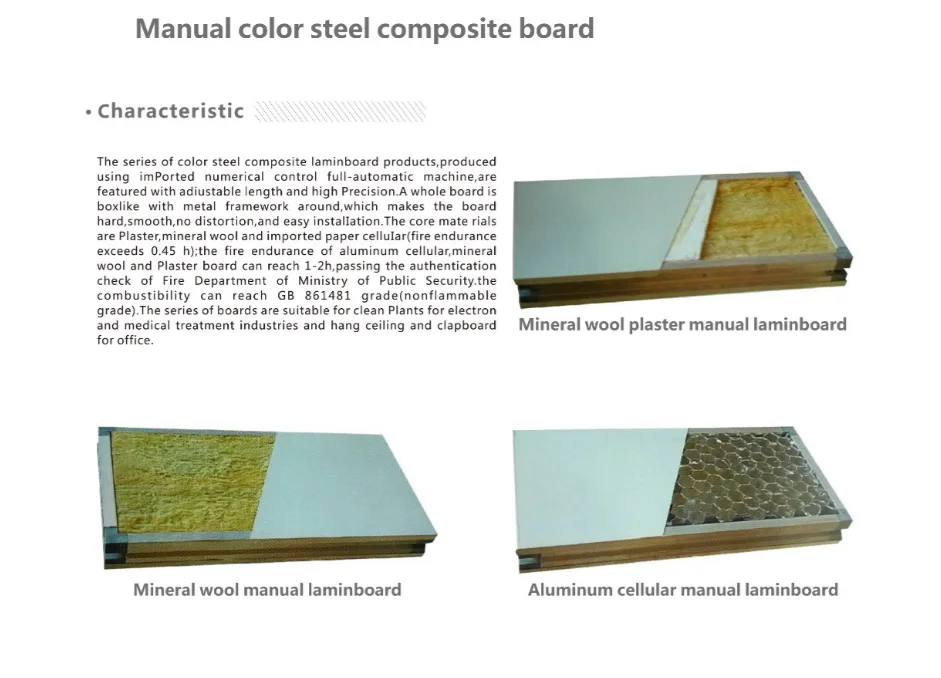

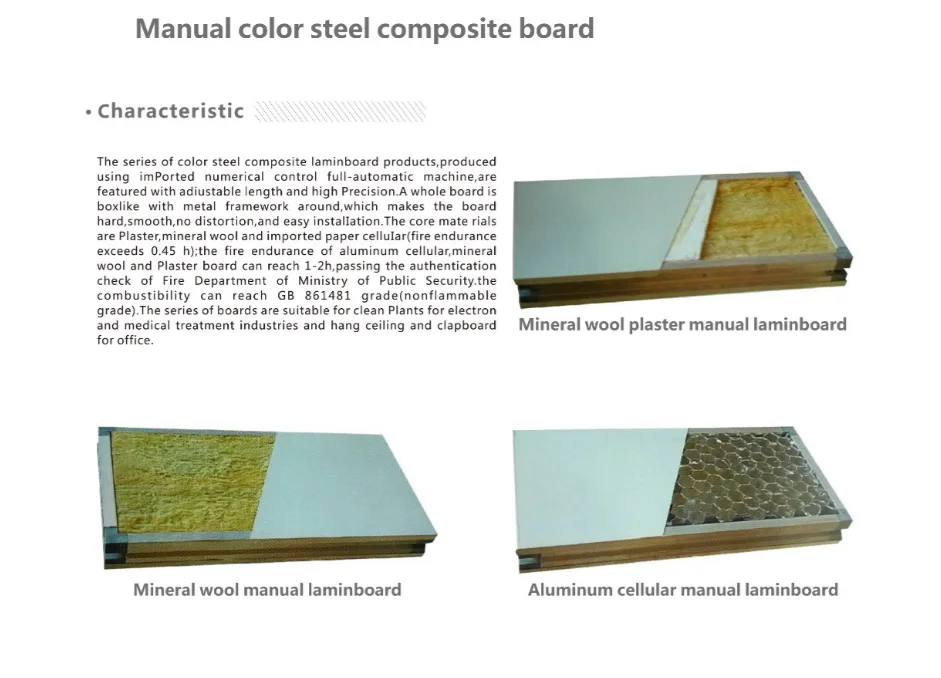

WALL PANELS & FALSE CEILING.

The wall panel for the general clean room areas has been designed with a sandwich panel type with insulating soul of polyurethane of 42Kg/m³ ,both side with glass magnesium board and(T:5mm) .Total panel thickness is 50mm and the ceiling panel for the general clean room areas has been designed with a sandwich panel type with insulating soul of polyurethane of 42Kg/m³ ,both side with glass magnesium board and(T:5mm) . and thickness of 50mm,the faces are made of galvanized steel sheets of 0.5mm covered with a primary coating of epoxy and other polyurethane vanish coating of melted in oven. Joints should be sealed with silicon to complete the tightness. The 4 sides of the panel core are reinforced with aluminum profiles which enhances the rigidity of the panel.

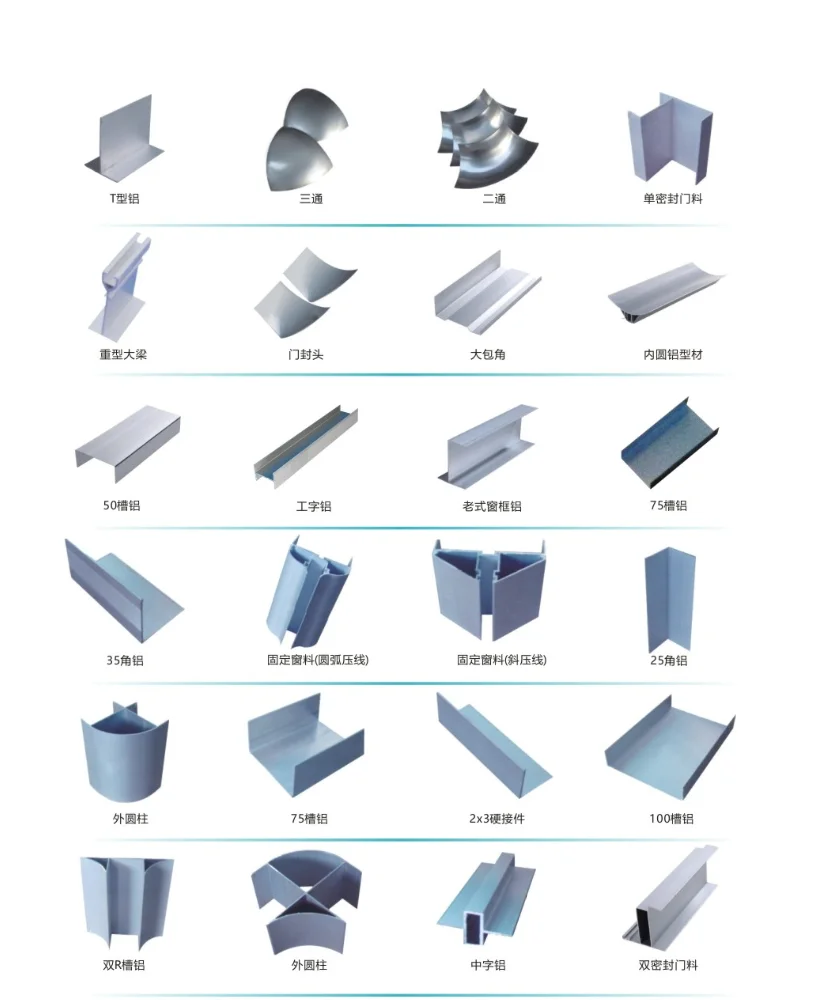

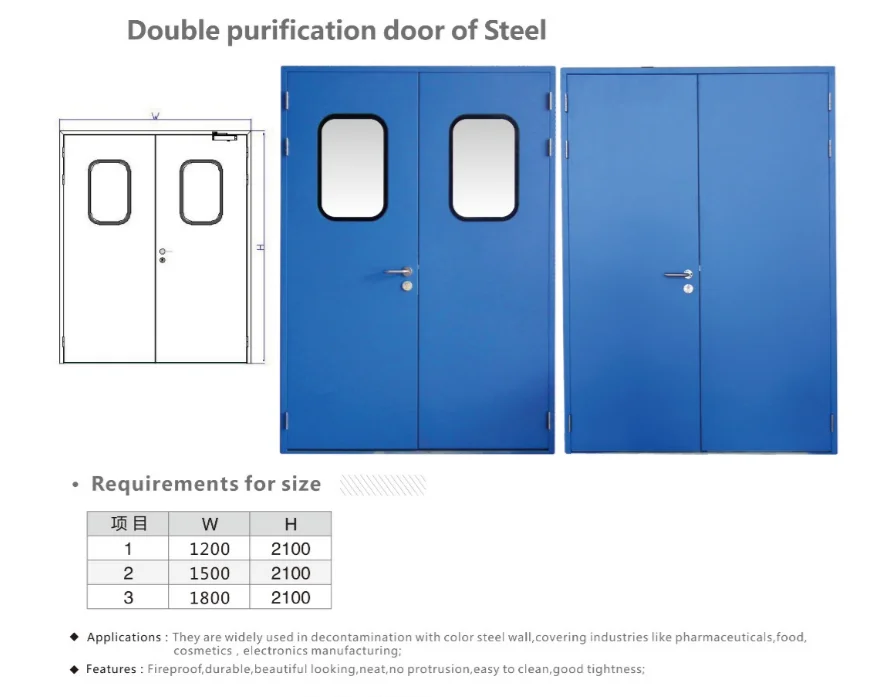

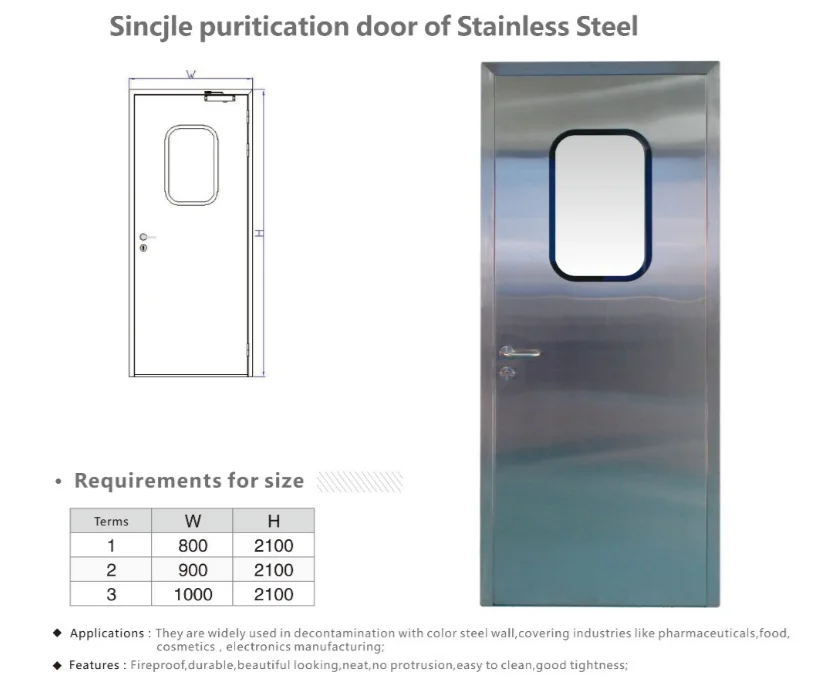

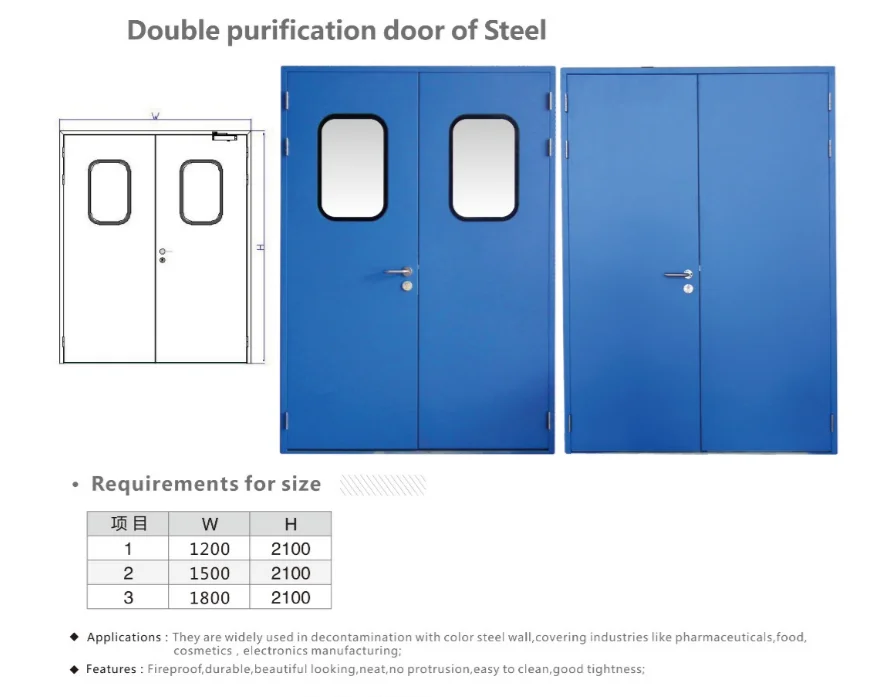

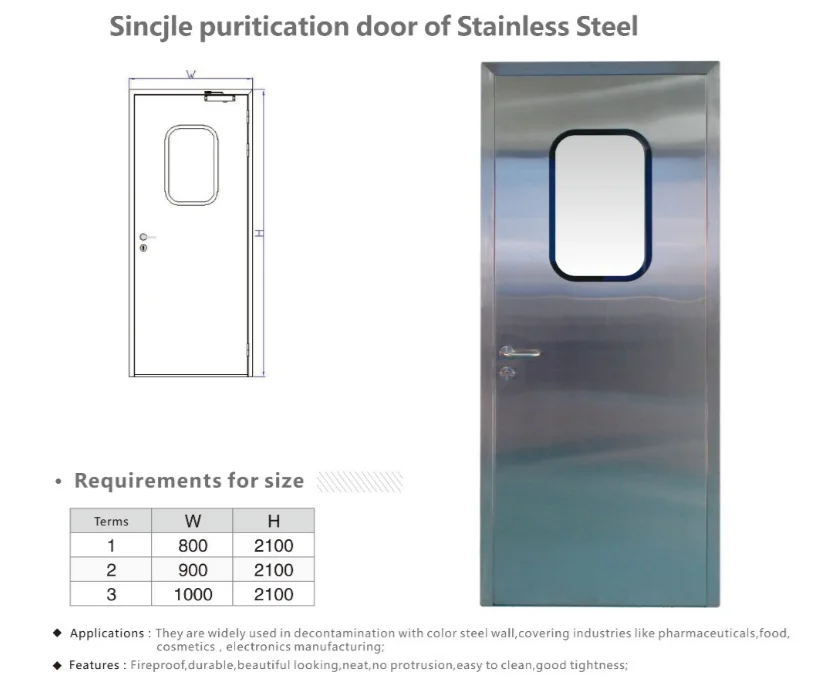

DOORS.

The doors are made with the same structure of the panel, steel sandwich panel with polystyrene body. The door has all around a specifically designed aluminum profile to allow the easy cleaning. The profile is especially flush mounted with the body of the door with no steeply joints. The whole body of the door is flush mounted in both sides to the wall panel.

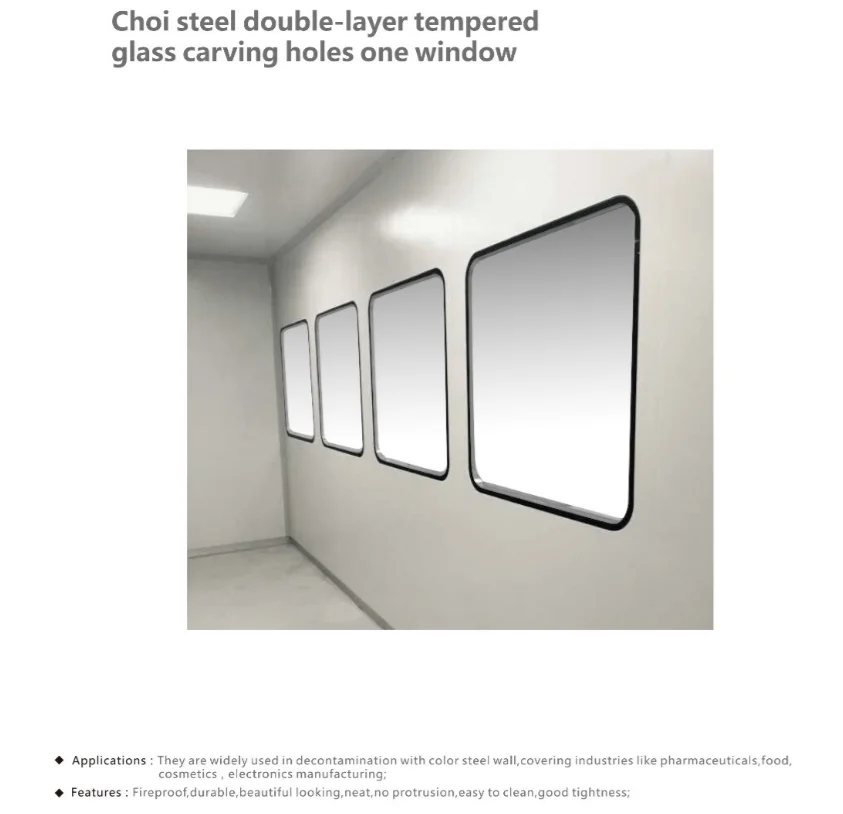

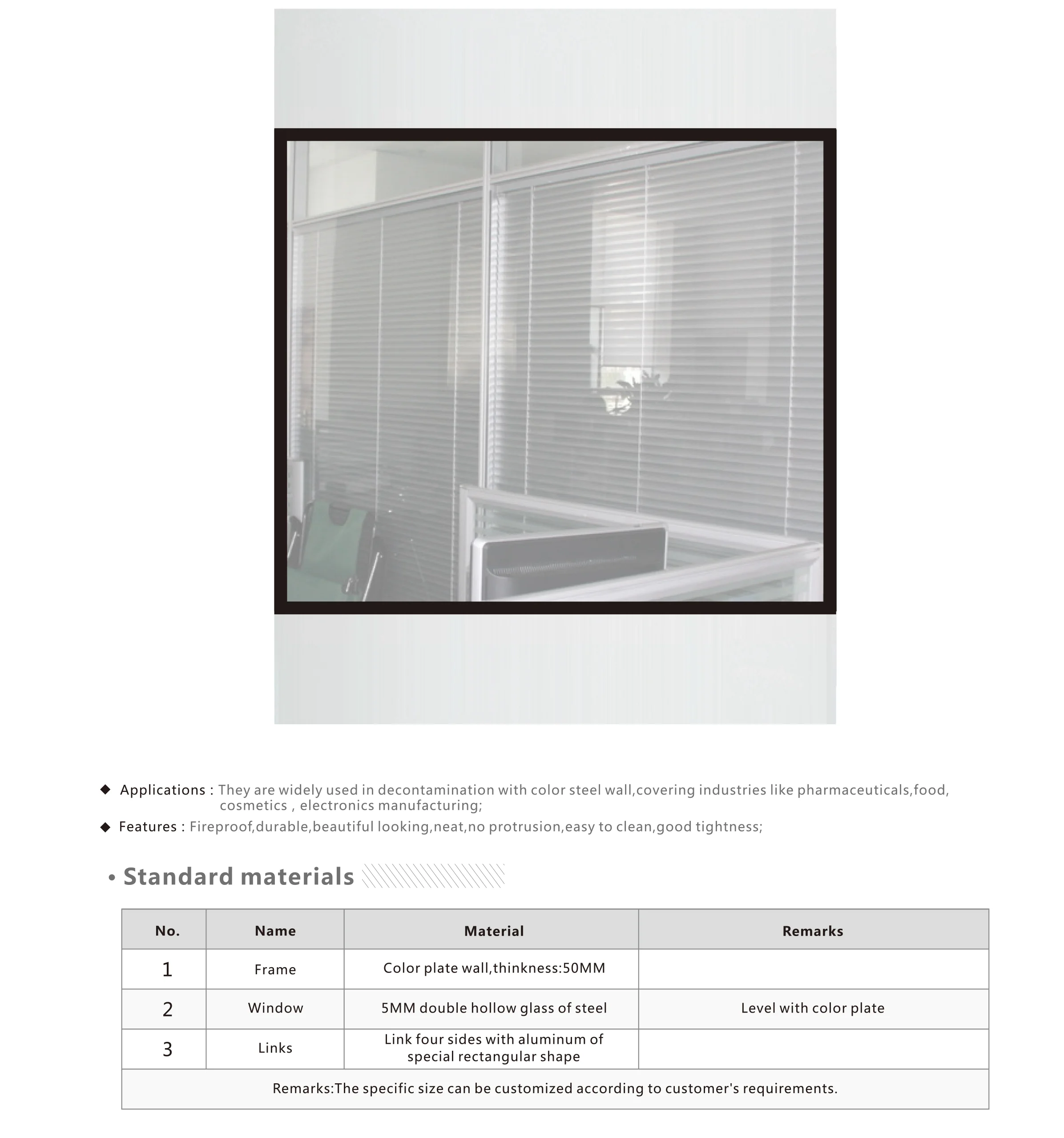

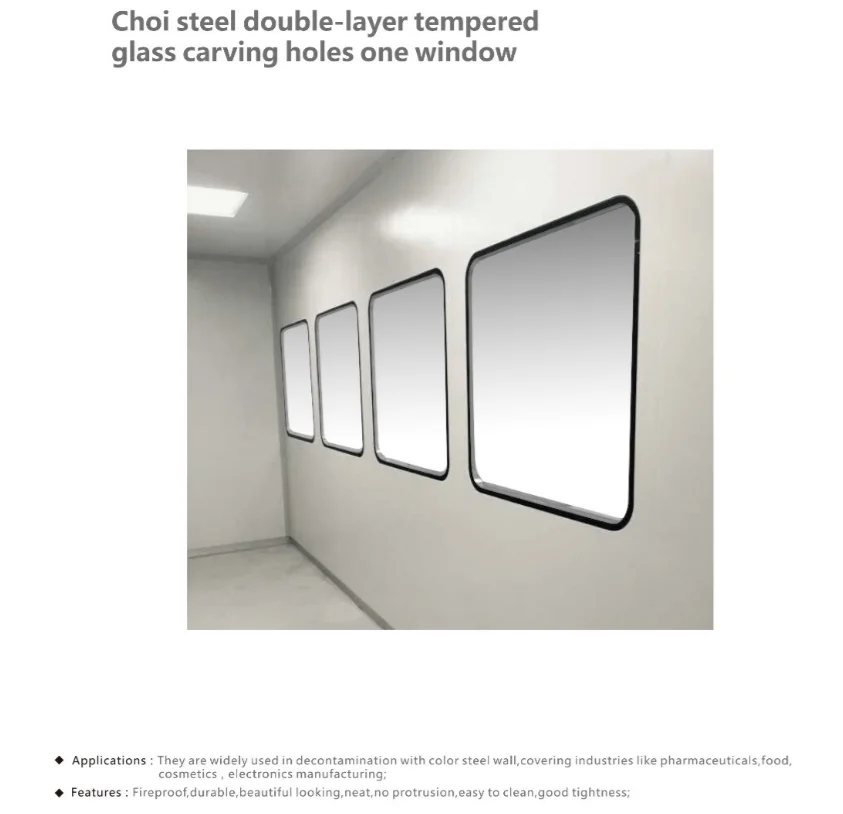

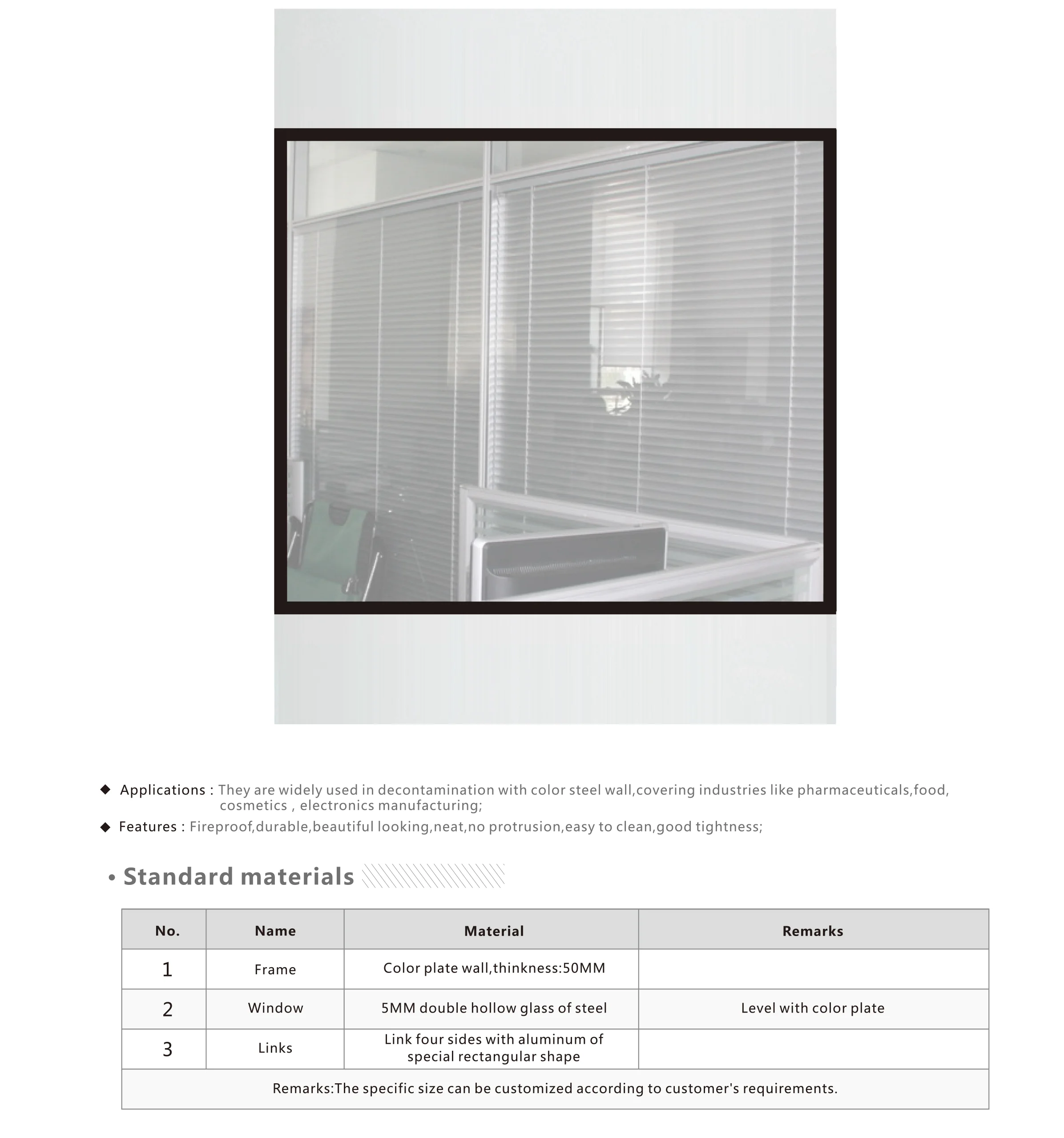

WINDOWS.

Double Side Glass window, flush mounted design

Double glass made of 5mm glasses

Connection Profile: Extruded aluminum profile

Double glass made of 5mm glasses

Connection Profile: Extruded aluminum profile

HVAC ACCESSORIES IN CLEAN ROOM.

In the clean room, all the HVAC related accessories will be perfectly integrated, in order to obtain a complete compliant

environment. The selection, dimensioning and location of all the HVAC related elements to be installed inside the rooms will be part of the detailed engineering paying special attention to several facts, such as proper air flow pattern design, environment blow up, particles removal, no dead areas remaining, proper temperature and humidity distribution, avoid stratification of air in the rooms and so It is important to consider the equipment to be installed inside the clean areas when designing the air flow pattern, in order to avoid particles deposits in critical equipment areas, as well as to blow up with fresh air the heat parts and elements of the installed equipment, avoiding thermal bags inside the area. All the other HVAC elements such as temperature, transmitter devices will be installed preferred in the return ducts to be easily

maintained.

environment. The selection, dimensioning and location of all the HVAC related elements to be installed inside the rooms will be part of the detailed engineering paying special attention to several facts, such as proper air flow pattern design, environment blow up, particles removal, no dead areas remaining, proper temperature and humidity distribution, avoid stratification of air in the rooms and so It is important to consider the equipment to be installed inside the clean areas when designing the air flow pattern, in order to avoid particles deposits in critical equipment areas, as well as to blow up with fresh air the heat parts and elements of the installed equipment, avoiding thermal bags inside the area. All the other HVAC elements such as temperature, transmitter devices will be installed preferred in the return ducts to be easily

maintained.

Packing & Delivery