Автоматическая ультразвуковая машина для стегания

- Категории: Home Textile Product Machinery >>>

- Поставщик: Dongguan,Chuangyu,Ultrasonic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Bed Sheets Ultrasonic Embossing Quilting Machine

Details Images

Products Description

Decription of Bed Sheets Ultrasonic Embossing Quilting Machine

Ultrasonic quilting machine, also known as “ultrasonic composite creasing machine,” is a high-frequency oscillation that transmits sound waves from the welding head to the welding surface of the work object, causing friction between the work object molecules to achieve cloth and cloth, cloth and chemical fiber cotton, plastic film It can be welded with plastic film and other materials, fabrics and spray cotton, non-woven fabric, sponge and other materials. Ultrasonic automatic stitching and welding time is short, no need to use needles and threads, and the trouble of frequent needle changes are eliminated. The stitching speed is faster than sewing machine quilting There are many, the width is freely determined. Because there is no needle stitching process, it effectively avoids the occurrence of broken needles in the material. The product produced has strong adhesion, clear embossing, and three-dimensional relief on the surface. The product is more beautiful and has no needles. The hole is impermeable and has the function of waterproof and warming; the use of roller molds, easy to change molds, can be pressed to produce a variety of complex and non-continuous and symmetrical patterns, automatic control of frequency modulation and speed, torque motor, constant winding tension, Automatic correction function, correct each layer of material, keep the multi-layer material in alignment, the material is smooth and consistent, the processing loss is low, and the product is smooth and stable.

Whole machine structure: Five parts consisting of ultrasonic electric console, embossing machine, air conditioner cooling, cloth rack, and coil mechanism

Whole machine structure: Five parts consisting of ultrasonic electric console, embossing machine, air conditioner cooling, cloth rack, and coil mechanism

Product Paramenters

Name | Bed Sheets Ultrasonic Embossing Quilting Machine |

Model: | CY-CP12 |

Speed | 0-30m/min |

Frequency | 15/25KHz |

Power supply | 380V / 50HZ |

Working environment temperature | ≤28℃ |

length of flower roller | 1850MM (Custom-made available) |

roller diameter | diameter : 136MM |

Motor power | 2.2 KW +0.75KW |

Dimension | 7800*5800*2200mm |

Features Of Bed Sheets Ultrasonic Embossing Quilting Machine

1.The machine adopts advanced ultrasonic technology which is higher automate comparing with ordinary machines.

2.The material feeding is controlled by magnetic powder tension system and automatically correcting system,so the tension is evenly while feeding the materials.

3.The finishing cutting edge is smooth,no raw or curl edge and no color fading.Meanwhile,the cutting width can be adjustable.

4.It equipped with Japanese servo motor and original SMC pneumatic components to ensure the machine running stable.

5.It's a national patented product with functions of slitting,cutting and rewinding.

2.The material feeding is controlled by magnetic powder tension system and automatically correcting system,so the tension is evenly while feeding the materials.

3.The finishing cutting edge is smooth,no raw or curl edge and no color fading.Meanwhile,the cutting width can be adjustable.

4.It equipped with Japanese servo motor and original SMC pneumatic components to ensure the machine running stable.

5.It's a national patented product with functions of slitting,cutting and rewinding.

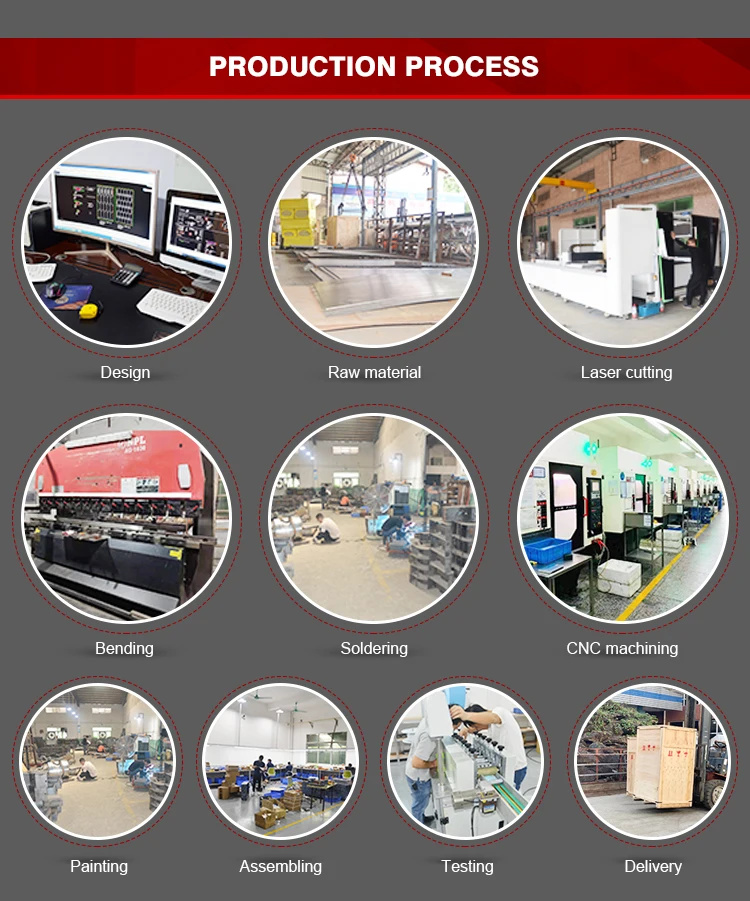

Manufacturing Technique

Company Profile

FAQ

1) Lead time for the Bed Sheets Ultrasonic Embossing Quilting Machine ?

In 25 working days

2) Warranty of Bed Sheets Ultrasonic Embossing Quilting Machine ?

1 year

3) How to Ship the : Bed Sheets Ultrasonic Embossing Quilting Machine ?

Recommend by sea, or by sea, if urgent , by air also available

4) Is it factory direct supply for this Ultrasonic Quilting and Sewing Machine ?

Yes,