Пустые металлические фильтры для сигарет с

- Категории: >>>

- Поставщик: Dongguan,Dafeng,Model,Co.,Ltd.Dongguan,Ltd.

Поделиться:

Описание и отзывы

Характеристики

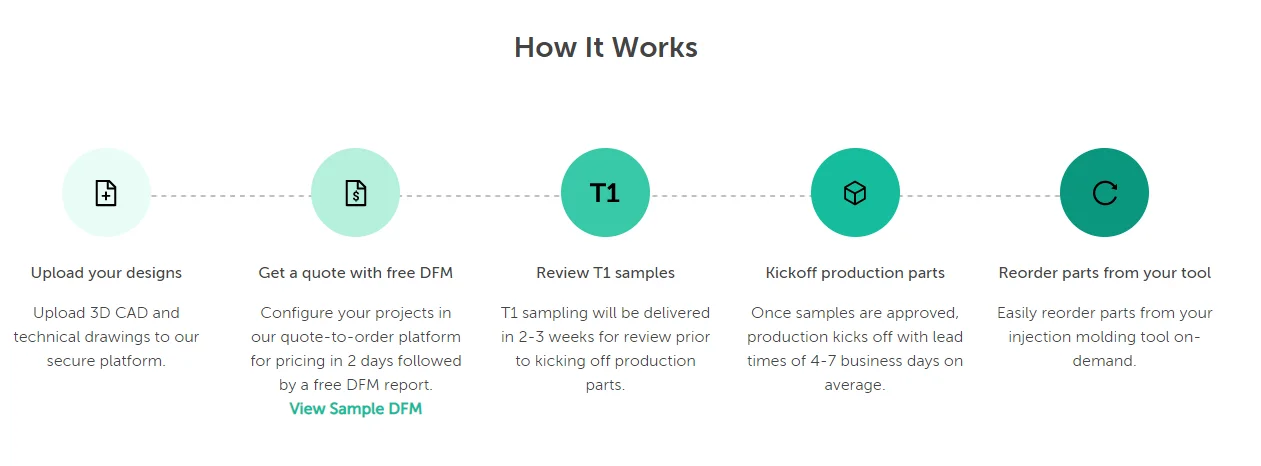

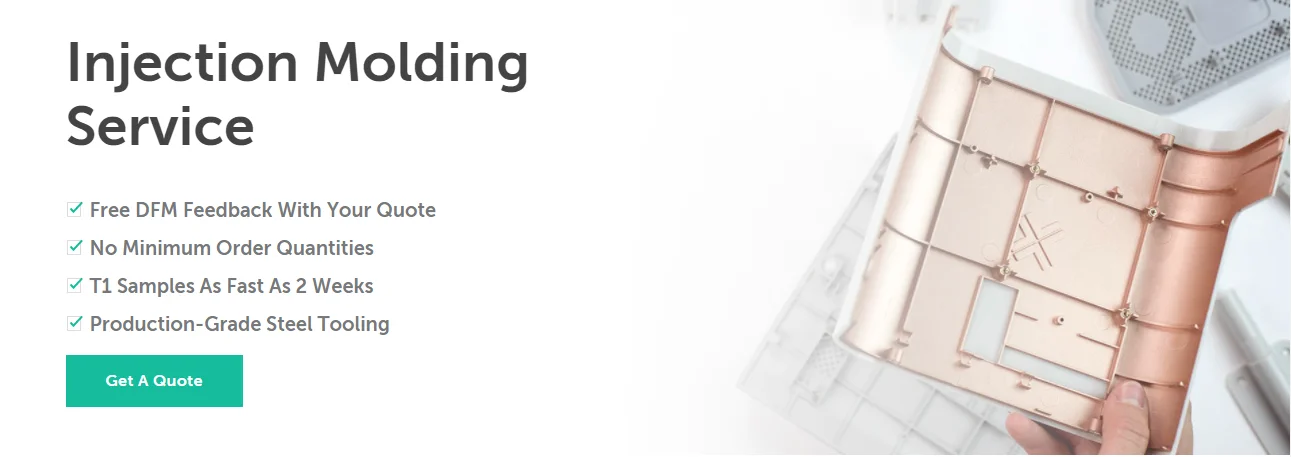

What Is Injection Molding?

Injection molding is the most commonly used method for producing higher volumes of plastic parts.

We use advance machines and technologies with project management and quality assurance for efficient, cost-effective tooling and injection molding operations.

Rapid Delivery of Injection Molded Parts

Mature Injection Molding Production Capabilities

Injection Molding Solutions Across Product Development

We use advance machines and technologies with project management and quality assurance for efficient, cost-effective tooling and injection molding operations.

Rapid Delivery of Injection Molded Parts

Need low-volume parts quickly? Depending on your project requirements, our Fast Track injection molding can deliver parts in as little as ten days.

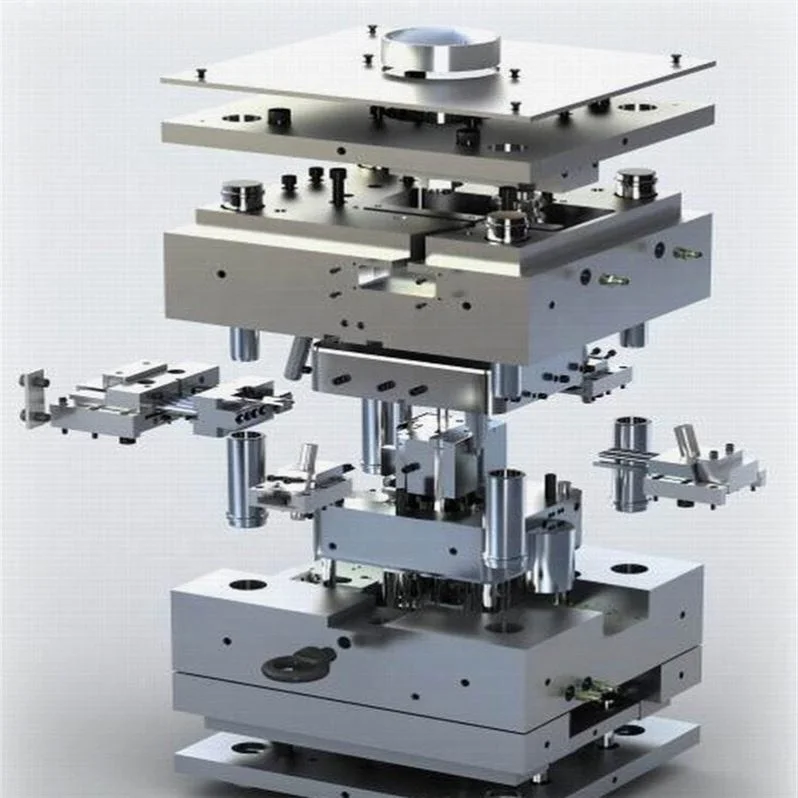

Mature Injection Molding Production Capabilities

Access cutting-edge tooling manufacturing facilities, including high-speed CNC machines, EDM machines and press sizes up to 800 tons.

These precise tooling operations complement our state-of-the-art injection molding capabilities.

These precise tooling operations complement our state-of-the-art injection molding capabilities.

Injection Molding Solutions Across Product Development

For new design verification utilizing our prototyping to production services in our state of the art facilities, we aim to provide end to end product development life cycle solutions.Injection molding is an ideal alternative to 3D printing for parts at a better cost per piece and in materials not available in 3D printing.

* Produce high volumes of consistent production parts with near-limitless plastic material options.

RAPID DELIVERY

* Our proprietary tooling methods allow us to deliver low-volumes of parts within one to two weeks.

QUALITY PRODUCTION PARTS

* Get precise, repeatable parts throughout large production at the quality you expect.

Injection Molding Processes

We can gives you easy access to diverse capabilities to serve all your manufacturing needs.Our injection molding service allows you to seeminglessly move from prototyping to end-part production.

Custom Plastic Injection Molding

Steel tooling with rapid lead times, ideal for prototyping, design validation, and bridge production.

Overmolding

Rubber or silicone molding over an existing plastic part.

Insert Molding

Plastic injection molding around a preformed, often metal threaded, insert.

Rapid tooling

Molds with aluminum inserts with a life time of up to 20,000 runs. Machined in typically 2-3 weeks.

Family Molds

Several parts are designed into the same mold tool. This allows for the minimization of tooling costs.

Multi-cavity molds

Multiple identical cavities are machined into the mold tool. This allows for more parts to be produced per shot, minimizing the unit costs.

Injection Molding Materials

All thermoplastics can be injection molded. Some thermosets and liquid silicones are also compatible with the injection molding process.

Material | Description | Benefits | Applications | Remarked |

ABS | Common thermoplastic with good impact resistance and toughness. | * Good impact resistance with toughness and rigidity * Metal coatings have excellent adhesion to ABS * Excellent processability and appearance | * Computer housings * Musical instruments (recorders & plastic clarinets) * Telecom devices * Small appliances (enclosures) * Automotive (interior trim, wheel covers, emblems) * Medical components | |

Polypropylene | Thermoplastic polymer used for a wide number of applications. | * Excellent moisture resistance * Food grades available * Mold–in hinge possible * Good impact strength | * Packaging * Industrial components for fluid processing * Household goods * Automotive * Electrical hardware | |

Polyoxymethylene (POM) | Dimensionally stable thermoplastic with high stiffness and low friction. | * High tensile strength with rigidity and toughness * Good impact and solvent resistance * Glossy molded surface * Low static and dynamic coefficients of friction (slippery) * Many grades have FDA and NSF approvals on food and water contact * Replace die-cast metal components | * Mechanical automotive * Business machines * Household appliance * Gears * Bushings * Door handles * Seat belt parts | |

Polycarbonate | Thermoplastic material with good temperature resistance and impact strength. | * High impact resistance * Clarity * Dimensional stability * Chemical resistance (PC blends) | * Automotive headlights * Business machines * Consumer products * Telecommunications * Medical products * Mechanical goods | |

Polycarbonate / ABS | Blend of PC and ABS that creates strong parts for a variety of applications. | * Good impact resistance with toughness and rigidity * Metal coatings have excellent adhesion to ABS * Very good indoor UV light color stability * Excellent processability and appearance | * Automotive exterior and interior components * Medical hardware * Electrical housings * Computers * Monitors * Business equipment housings * Enclosures | |

PVC | PVC is a polymer with good insulation properties, high hardness, and good mechanical properties. | * Wide range of flexibility * Flame retardant * Dimensional stability * Low cost | * Medical/healthcare products * Automotive applications * Household items * Electronic extruded wire covering | |

Nylon | Polymer material that is durable with high elongation and good abrasion resistance. | * Temperature capability 600°-700° for short term * Excellent chemical resistance * High resistance to abrasion * Tough and withstands repeated impact | * Automotive components * Bearings * Electronic connectors * Gears * Consumer products * Industrial products | |

Acrylic (PMMA) | Material with resistance to breakage often used for transparent applications. | * Excellent optical clarity * Excellent weatherability and resistance to sunlight * Rigid with good impact resistance * Good light transmission | * Automotive transparent items such as head/tail lenses and trim * Household light fixtures and decorative items * Safety equipment and shields | |

Polystyrene | Light weight material popular for its high impact strength and toughness. | * Optical clarity * High gloss * FDA grades available * Low cost * Good dimensional stability * Good rigidity | * Household goods * Containers * Furniture * Housings * Packaging | |

Polyetherimide (PEI) | Thermoplastic with high heat resistance and excellent mechanical properties. | * High heat resistance * Exceptional strength and impact modulus * High dielectric strength * Broad chemical resistance * Biocompatible * Excellent machinability and finishing characteristic * Outstanding processability on conventional molding equipment * Flame resistance with low smoke evolution | * Commercial aircraft interiors * Healthcare products * Cooking utensils * Fiber optics * Electrical products * Electronic parts | |

Nylon + Glass Fiber | Polymer with excellent mechanical stiffness and elevated temperature resistance. | ****** | ******* | |

................. | ||||

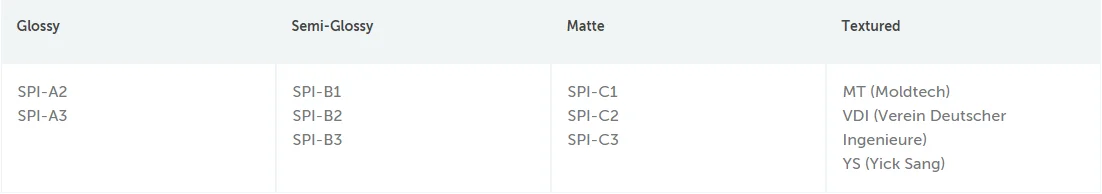

Injection Molding Finishes

Injection molded parts are not usually post-processed, but the mold itself can be finished to affect the surface finish of the molded part.

This way aesthetic needs or technical requirements can be achieved.

This way aesthetic needs or technical requirements can be achieved.

Heat Staking

The process of locally heating a plastic component in order to reform and insert another component (such as a threaded insert).

Laser Engraving

Engraving text or a design with the use of a laser.

The process of locally heating a plastic component in order to reform and insert another component (such as a threaded insert).

Laser Engraving

Engraving text or a design with the use of a laser.

Pad Printing

A process to apply an ink-based, 2D design to a 3D surface.

Painting

Primer and top coat; standard colors or Pantone matching; masking available; EMI (copper) paint.

Ultrasonic Plastic Welding

A high frequency welder generates heat to join or reform thermoplastics.

A process to apply an ink-based, 2D design to a 3D surface.

Painting

Primer and top coat; standard colors or Pantone matching; masking available; EMI (copper) paint.

Ultrasonic Plastic Welding

A high frequency welder generates heat to join or reform thermoplastics.

From Prototype to Production

Rapid Design Molds

Ideal for part design validation, low volume production, and bridge production quantities.

* No minimum order quantities

* Complex designs accepted

* Steel tooling

* No minimum order quantities

* Complex designs accepted

* Steel tooling

Production Tooling

Ideal for higher volume production parts, starting at 10,000 units. Tooling costs are higher than Rapid Design Molds, but tooling

construction allows for lower part pricing.

* Up to 1M molding shots

* Steel tooling & multi-cavity tooling

* Automatic tooling actions

Ideal for higher volume production parts, starting at 10,000 units. Tooling costs are higher than Rapid Design Molds, but tooling

construction allows for lower part pricing.

* Up to 1M molding shots

* Steel tooling & multi-cavity tooling

* Automatic tooling actions

Your Injection Molding Success Team

All injection molding orders a team of dedicated Da Feng working tirelessly behind the scenes to ensure your parts are manufactured on time and to your precise specifications.

Application

Injection moulding is used to create many things such as wire spools, packaging, bottle caps, automotive parts and components, toys, pocket combs, some musical instruments (and parts of them), one-piece chairs and small tables, storage containers, mechanical parts (including gears), and most other plastic products........

Industrial production

Consumer electronics

Medical equipment

.

Education

Auto parts

Package

Aeronautics and astronautics

Furniture appliances

Construction industry

Injection molding precise parts takes a team of experts, ensuring well-built tooling and smooth processes offshore and onshore.

At Da Feng, our injection molding services are backed by decades of manufacturing experience and a tireless team of project managers ready to assist you every step of the way.

How We Guarantee Injection Molding Quality

Working with customers across a variety of industries, we’ve developed thorough methods to provide solutions for fast tooling and complementary post-processing in order to serve your versatile needs.

At Da Feng, our injection molding services are backed by decades of manufacturing experience and a tireless team of project managers ready to assist you every step of the way.

How We Guarantee Injection Molding Quality

Working with customers across a variety of industries, we’ve developed thorough methods to provide solutions for fast tooling and complementary post-processing in order to serve your versatile needs.

Who we are?

Dongguan Da Feng is a verified Manufacturer of Alibaba that rapidly delivers custom parts on-demand, to help companies accelerate new products introduction to innovate with agility, de-risk their supply chains, and get products to market faster.

Our company established in March 2018. Located in Dongguan City, which enjoys convenient transportation and high technology. Now we specialize in rapid prototyping, rapid tooling and low-volume manufacturing/mass production of custom plastic and metal parts, especially for action figures and toy, PVC gift figurine,plastic cover, metal metalwork. Our international team of engineers and technicians use advanced equipment and techniques like 3D printing,CNC machining,Vacuum casting,Mold making and production to turn your designs into reality quickly at a good price. Also we offer different surface treatments, such as painting, screen-printing, plated,anodizing. In this way, we can offer One-Stop-Service from Design to mass production.

With the continuous expansion of production, innovation of new products, upgrading of technology, strengthening of management, we become bigger and stronger. Therefore, the company's products meet requirements of customers, strive to market competition in a

steady winning. We can make everything into reality.Since we own the excellent clerks,advanced machines and rich experience, we can make everything for you.

Contact us today and it will save you more time and cost.

Contact us now!

With the continuous expansion of production, innovation of new products, upgrading of technology, strengthening of management, we become bigger and stronger. Therefore, the company's products meet requirements of customers, strive to market competition in a

steady winning. We can make everything into reality.Since we own the excellent clerks,advanced machines and rich experience, we can make everything for you.

Contact us today and it will save you more time and cost.

Contact us now!

Make better products and service go over world!

Let Da Feng person developed with company together and achieve their dream.

Do you offer molding options other than injection molding?

Although injection molding is most popular, Da Feng offers a variety of high- and low-volume molding processes, including urethane casting and tooling for composite layup.

Contact your project engineer to learn more.

Although injection molding is most popular, Da Feng offers a variety of high- and low-volume molding processes, including urethane casting and tooling for composite layup.

Contact your project engineer to learn more.

Q1: Are you a trading company or factory?

A: We are direct factory with experienced engineers and employees as well as approximate 3000 square meters workshop area.

Q2: Can you provide free sample?

A: Free samples are not available for the custom parts. But we will return the sample charge after you place the order.

Q3: what is the MOQ is for this product in your company?

A: MOQ is 1 pcs.

Q4:Which 3d drawing files should go with the machines?

A: CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, For *STL format,it goes with 3d printer and SLA.

Q5:Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q6:What shall we do if we do not have drawings?

A:Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), 3D file will be made for you if placed order.

Q7: What is your terms of payment?

A: Payments<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance balance before shippment.

A: We are direct factory with experienced engineers and employees as well as approximate 3000 square meters workshop area.

Q2: Can you provide free sample?

A: Free samples are not available for the custom parts. But we will return the sample charge after you place the order.

Q3: what is the MOQ is for this product in your company?

A: MOQ is 1 pcs.

Q4:Which 3d drawing files should go with the machines?

A: CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, For *STL format,it goes with 3d printer and SLA.

Q5:Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q6:What shall we do if we do not have drawings?

A:Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), 3D file will be made for you if placed order.

Q7: What is your terms of payment?

A: Payments<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance balance before shippment.

Похожие товары

Формы для высечки под заказ, форма для кожаного ножа

US $8.30-$8.60

Силиконовые формы для литья смолы

US $0.50-$5.00