Coating protective film machine tape casting production line

- Категории: Plastic Blowing Machines >>>

- Поставщик: Wuhan,Handern,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

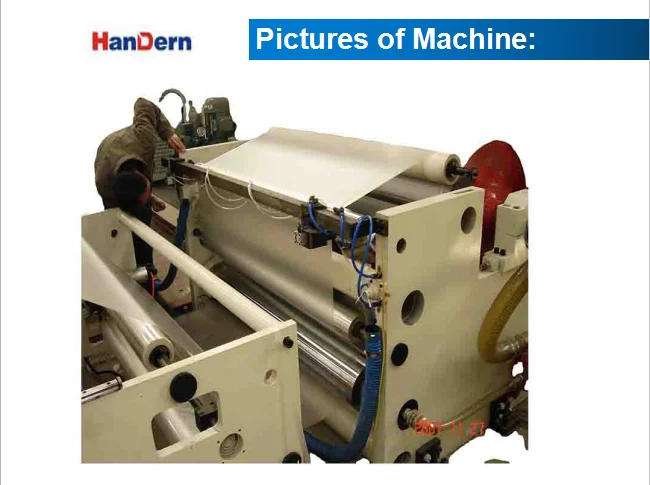

Coating protective film machine tape casting film production line tape casting film making machine

Brief Intorduction:

The production line is a high-speed extrusion compounding line for flexible packaging materials. It is suitable for coating coated grade resin such as LDPE, LLDPE, PP, EVA, EAA, EMAA, etc. It is used in the production of flexible packaging composite film materials such as food, medicine and electronics.

Technical Parameter:

High-speed extrusion lamination compound production line

Color printing flexible packaging

| Model | Product width(mm) | Lamination thickness(mm) | Max.extrusion Capacity | Design line speed |

| XD-CFLM-1200 | 600-1100 | 0.01-0.05 | 250kg/h | 200m/min |

| XD-CFLM-1450 | 800-1350 | 0.01-0.05 | 300kg/h | 200m/min |

| XD-CFLM-1700 | 1000-1600 | 0.01-0.05 | 400kg/h | 200m/min |

Release paper, label paper

| Model | Product width(mm) | Lamination thickness(mm) | Max.extrusion Capacity | Design line speed |

| XD-GPLM-1200 | 600-1100 | 0.01-0.05 | 250kg/h | 220m/min |

| XD-GPLM-1450 | 800-1350 | 0.01-0.05 | 330kg/h | 280m/min |

| XD-GPLM-1700 | 1000-1600 | 0.01-0.05 | 400kg/h | 280m/min |

Liquid aseptic packaging

| Model | Product width(mm) | Lamination thickness(mm) | Max.extrusion Capacity | Design line speed |

| XD-GFLM-1200 | 600-1100 | 0.01-0.04 | 100kg/h(φ65) 250kg/h(φ90) | 280m/min |

| XD-GFLM-1450 | 800-1350 | 0.01-0.04 | 180kg/h(φ80) 300kg/h(φ100) | 280m/min |

Pre-coated film

| Model | Product width(mm) | Lamination thickness(mm) | Max.extrusion Capacity | Design line speed |

| XD-TFLM-1700 | 1000-1600 | 0.01-0.04 | 300kg/h | 200m/min |

| XD-TFLM-2100 | 1400-2000 | 0.01-0.04 | 400kg/h | 200m/min |

Paper cup use paper

| Model | Product width(mm) | Lamination thickness(mm) | Max.extrusion Capacity | Design line speed |

| XD-GLM-1200 | 600-1100 | 0.01-0.04 | 250kg/h | 220m/min |

| XD-GLM-1450 | 800-1350 | 0.01-0.04 | 350kg/h | 280m/min |

| XD-GLM-1700 | 1000-1600 | 0.01-0.04 | 400kg/h | 280m/min |

The configuration of machines can be CUSTOMIZED according to your needs!

| Serial Number | High Speed Extrusion Lamination Compound Production Line | Unit |

| 1 | Unwinding | one set |

| 2 | Corona treatment | one set |

| 3 | Coating | one set |

| 4 | Oven | one set |

| 5 | Loading | one set |

| 6 | Extruder | one set |

| 7 | Die | one set |

| 8 | Casting forming | one set |

| 9 | Lamination | one set |

| 10 | Corona treatment | one set |

| 11 | Inspection | one set |

| 12 | Winding | one set |

| 13 | Control system | one set |

| 14 | Edge trimming | one set |

Extrusion casting molding and main applicaitons:

Plastic particles are extruded linearly from a flat die after being plasticized by a screw, and then attached to the surface of flexible substrates such as paper, film, non-woven fabric, woven fabric, etc. And finally get a composite material that combines the barrier properties and heat sealability of the plastic film layer, the strength and toughness of the substrate, and the functional characteristics.

The product is widely used in food, beverage, packaging and construction, etc.

1000#coating protective film machine coating hot melt adhesive compound machine tape casting film production machine

1000#coating protective film machine coating hot melt adhesive compound machine tape casting film production machine

1000#coating protective film machine coating hot melt adhesive compound machine tape casting film production machine

1000#coating protective film machine coating hot melt adhesive compound machine tape casting film production machine