Кованая сталь 1 2714 2738 2311 2312 4340 4130 легированная кованые круглые

- Категории: Steel Round Bars >>>

- Поставщик: Xingxiong,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Plactic mold steel

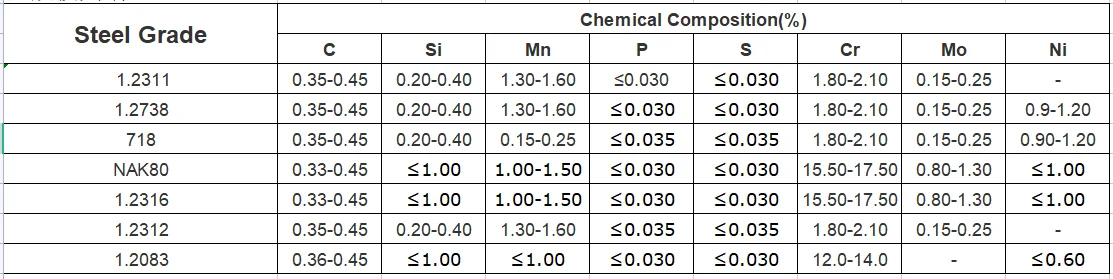

Product Name | High Quality Plastic Mould Steel |

Steel Grade | p20 1.2311 1.2738 1.2312 |

Specification | Round Bar: diameter 8mm – 3000mm Plate: thickness 10mm – 1500mm x width 200mm – 3000mm Grade Square: 20mm – 500mm |

Standard | AIS JIS DIN GB EN |

HS Code | 72283024 72254000 7208511000 |

Forging | Preheat the steel carefully, heat to 1150 oC – 1200 oC maximum, hold until temperature is uniform throughout the section. Do not forge below 850 oC.Following forging operation the work piece should be cooled as slowly as possible. |

Heat Treatment | Heat steels to 800 oC – 850 oC, hold until temperature is uniform throughout the section and cool in furnace. |

Hardness | Anneal: ≤220HB Q+T: 28-34HRC HEAT TREAT MENT 55-62HRC |

Application | 1. Develop materials that are easy to process and good in polishing With the production of optical disc, disk, prism and other precision parts, the demand for easy machining mirror steel increases. This kind of steel contains less non-metallic impurities, fine metallographic structure uniform, no fiber direction. It is the main development direction of plastic mold steel. 2. The corrosion resistant steel In the process of long-term operation and maintenance of the mold, it is easy to rust and corrosion, and with the addition of various components in plastic molding, the mold is more prone to corrosion. Therefore, it is required to improve the corrosion resistance of the base material body, and some corrosion-resistant stainless steel has been developed. 3. Maraging alloy steel This kind of steel has enough mechanical properties and outstanding process properties, especially high strength, toughness, wear resistance, low coefficient of thermal expansion, is a good steel for the manufacture of injection molding, but the price is expensive. 4. Cemented carbide Mainly used in the production of high life requirements, the production of large batch of molds |

Product Introduction: |

Plastic die steel is a kind of die steel used for plastic manufacture. Plastic mold materials are mainly die steel. The development of die steel has promoted the development of industrial products to the direction of high grade,diversification,individualization and high added value. All countries in the world have counted the output of die steel into alloy tool steel,which accounts for about 70% ~ 80% of alloy tool steel. Plastic die steel can be generally divided into six categories: aging hardening plastic die steel (including mirror die steel),corrosion resistant plastic die steel, carburizing plastic die steel, pre-hardening buried material die steel (including free cutting steel), tempering plastic die steel and quenching plastic die steel. The more widely used are aging hardening plastic die steels, carburizing plastic die steels and prehardening plastic die steels |

MAINLY SALE GRADE OF STEEL: PLASTIC MOULD STEEL: 1.2311, 1.2312, 1.2738, P20, 1.2083, 1.2316, NAK80, P40, 1.2738HH HOT WORK MOULD STEEL: 1.2344, SKD61, H13, H11, FDAC, 8407 COLD WORL MOULD STEEL: SKD11, D3, SKS3, 1.2080, 1.2379, CR12MOV, O1, D2 STRUCTURAL ALLOY STEEL: 4140, 20CR, 40Cr, 35CrMo, 42CrMo, 38CrmoAi, SCM440, SCM420, 1.7225 CARBON STEEL &: Q235, Gcr15, S45C, S50C, S55C |

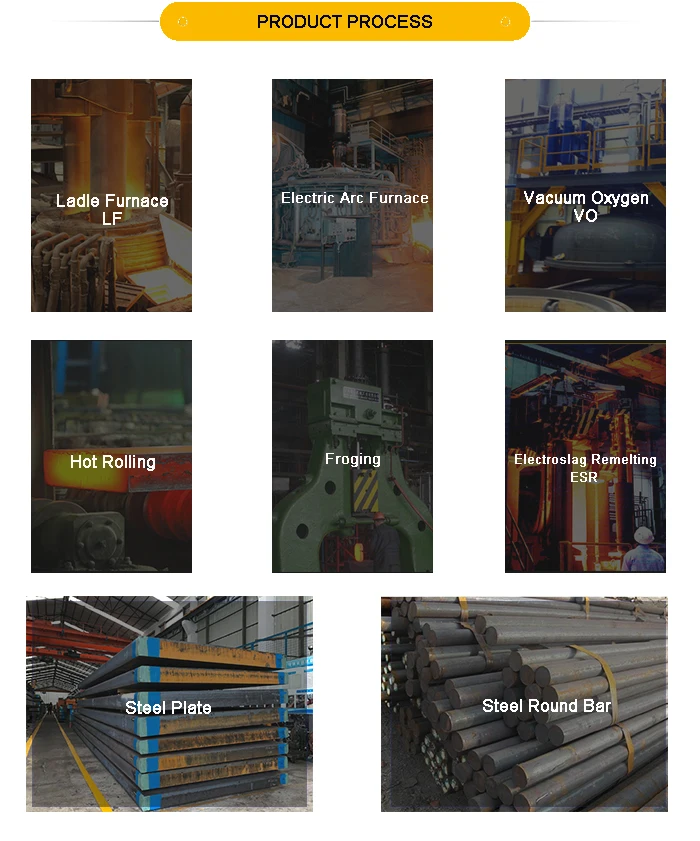

1.Steel Smelthing: (Ladle furance / Electric Arc Furnace / Vacuum oxygen ).

2.Steel Ingot: (Ingot Rolling / electroslag remelting furnace).

3.Steel Round Bar: (Steel Round Bar / Steel Plate ).

4.Finished: (Cutting / Milling / Surfacing Griding / Heat treatment / Round Steel Bar Turing).

2.Steel Ingot: (Ingot Rolling / electroslag remelting furnace).

3.Steel Round Bar: (Steel Round Bar / Steel Plate ).

4.Finished: (Cutting / Milling / Surfacing Griding / Heat treatment / Round Steel Bar Turing).

Our Service:

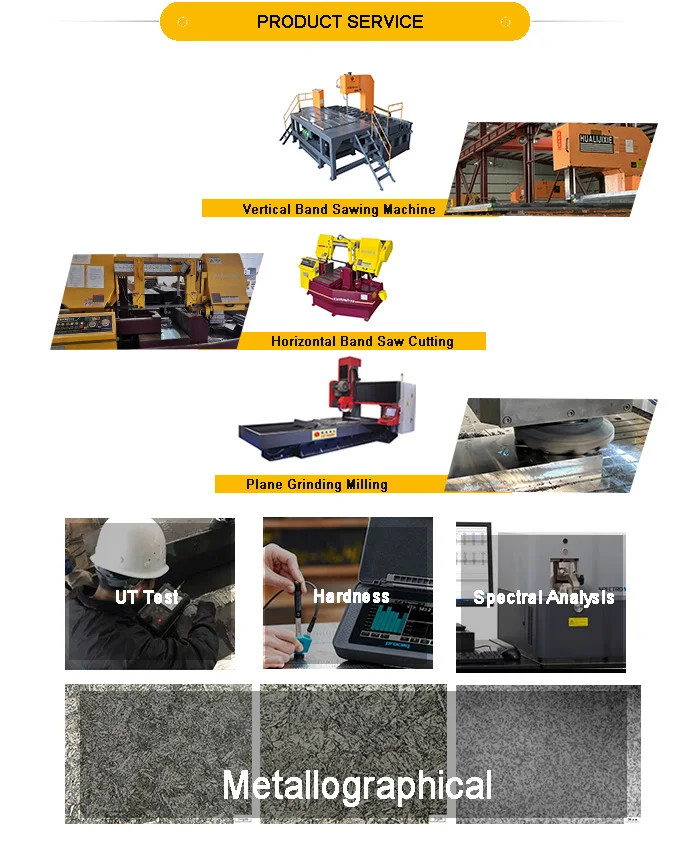

Cutting: Horizontal band saw cutting / Vertical band sawing machine

Milling:CNC surface grinding machine, NC side boring machine, Band saw,

CNC double head machine,Vertical Band saw, CNC milling machine,

Double alloy saw blade, wireless remote control crane, Magnetic chuck

Inspection: Hardness / Spectral Analysis / Ultrasonic testing, etc.

Milling:CNC surface grinding machine, NC side boring machine, Band saw,

CNC double head machine,Vertical Band saw, CNC milling machine,

Double alloy saw blade, wireless remote control crane, Magnetic chuck

Inspection: Hardness / Spectral Analysis / Ultrasonic testing, etc.

Loading Details & Delivery:

1) For abundant stock, 7-15 days.

2) For customized products, 25-35 days.

3) Customized: 40-60days.

2) For customized products, 25-35 days.

3) Customized: 40-60days.

FAQ:

Q1: What do you do for the control of the quality?

A1: Before loading into the container, our products will all be inspected by ultrasonic inspection. Quality Grade conforms to SEP 1921-84 E/e, D/d, C/c as per customer's request.

A1: Before loading into the container, our products will all be inspected by ultrasonic inspection. Quality Grade conforms to SEP 1921-84 E/e, D/d, C/c as per customer's request.

Q2:: What are your hot-selling products?

A2: D2/1.2379, H13/1.2344, CR12MOV, DC53, CR8, abundant stock for both plates and rounds. Competitive prices and short lead-time.

Q3: Can we visit your company and factory?

A3: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Q4: Are you a manufacturer or merely a trader?

A4: We are a group of companies and owned manufacturer bases and trading companies. We specialized in plastic mold steel, hot work mold steel, cold work mold steel, alloy steel for mechanical, high-speed steel, etc. All materials are of high quality and competitive price.

A2: D2/1.2379, H13/1.2344, CR12MOV, DC53, CR8, abundant stock for both plates and rounds. Competitive prices and short lead-time.

Q3: Can we visit your company and factory?

A3: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Q4: Are you a manufacturer or merely a trader?

A4: We are a group of companies and owned manufacturer bases and trading companies. We specialized in plastic mold steel, hot work mold steel, cold work mold steel, alloy steel for mechanical, high-speed steel, etc. All materials are of high quality and competitive price.