Ceramic Skateboard Bearings Manufacturer Ball

- Категории: Ceramic Ball Bearing >>>

- Поставщик: Mingke,International,Trade,(Shandong),Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Serve | OEM customization service |

Brand | Follow customer requirements |

Ceramic bearing

The performance comparison of four bearing materials: ordinary bearing steel AISI52100 (GCr15), stainless steel AISI440 (9Cr18), silicon nitride (Si3N4) and zirconium oxide (ZrO2). Ceramic bearing is an important mechanical basic part due to its metal bearing Unmatched excellent performance, high temperature resistance, super strength, etc. take the lead in the world of new materials. In the past ten years, it has been widely used in various fields of national economy and people's livelihood.

The first advantage is that since ceramics are almost not afraid of corrosion, ceramic rolling bearings are suitable for operation under harsh conditions full of corrosive media.

Second, because the density of the ceramic rolling ball is lower than that of steel, and the weight is much lighter, the centrifugal effect of the outer ring during rotation can be reduced by 40%, and the service life is greatly extended.

Third, ceramics are less affected by thermal expansion and contraction than steel, so when the bearing gap is constant, the bearing can be allowed to work in an environment where the temperature difference changes more drastically.

Fourth, since the elastic modulus of ceramic is higher than that of steel, it is not easy to deform when subjected to force, so it is beneficial to increase the working speed and achieve higher accuracy.

Ceramic bearings have the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetic and electrical insulation, oil-free self-lubrication, and high speed. It can be used in extremely harsh environments and special working conditions. It can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textiles, pumps, medical equipment, scientific research, national defense and military fields. High-tech products for the application of new materials.

The rings and rolling elements of ceramic bearings are made of all ceramic materials, including zirconia (ZrO2), silicon nitride (Si3N4), and silicon carbide (Sic). The retainer is made of PTFE, nylon 66, polyetherimide, zirconia, silicon nitride, stainless steel or special aviation aluminum, thereby expanding the application range of ceramic bearings.

The performance comparison of four bearing materials: ordinary bearing steel AISI52100 (GCr15), stainless steel AISI440 (9Cr18), silicon nitride (Si3N4) and zirconium oxide (ZrO2). Ceramic bearing is an important mechanical basic part due to its metal bearing Unmatched excellent performance, high temperature resistance, super strength, etc. take the lead in the world of new materials. In the past ten years, it has been widely used in various fields of national economy and people's livelihood.

The first advantage is that since ceramics are almost not afraid of corrosion, ceramic rolling bearings are suitable for operation under harsh conditions full of corrosive media.

Second, because the density of the ceramic rolling ball is lower than that of steel, and the weight is much lighter, the centrifugal effect of the outer ring during rotation can be reduced by 40%, and the service life is greatly extended.

Third, ceramics are less affected by thermal expansion and contraction than steel, so when the bearing gap is constant, the bearing can be allowed to work in an environment where the temperature difference changes more drastically.

Fourth, since the elastic modulus of ceramic is higher than that of steel, it is not easy to deform when subjected to force, so it is beneficial to increase the working speed and achieve higher accuracy.

Ceramic bearings have the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetic and electrical insulation, oil-free self-lubrication, and high speed. It can be used in extremely harsh environments and special working conditions. It can be widely used in aviation, aerospace, navigation, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textiles, pumps, medical equipment, scientific research, national defense and military fields. High-tech products for the application of new materials.

The rings and rolling elements of ceramic bearings are made of all ceramic materials, including zirconia (ZrO2), silicon nitride (Si3N4), and silicon carbide (Sic). The retainer is made of PTFE, nylon 66, polyetherimide, zirconia, silicon nitride, stainless steel or special aviation aluminum, thereby expanding the application range of ceramic bearings.

Product Show

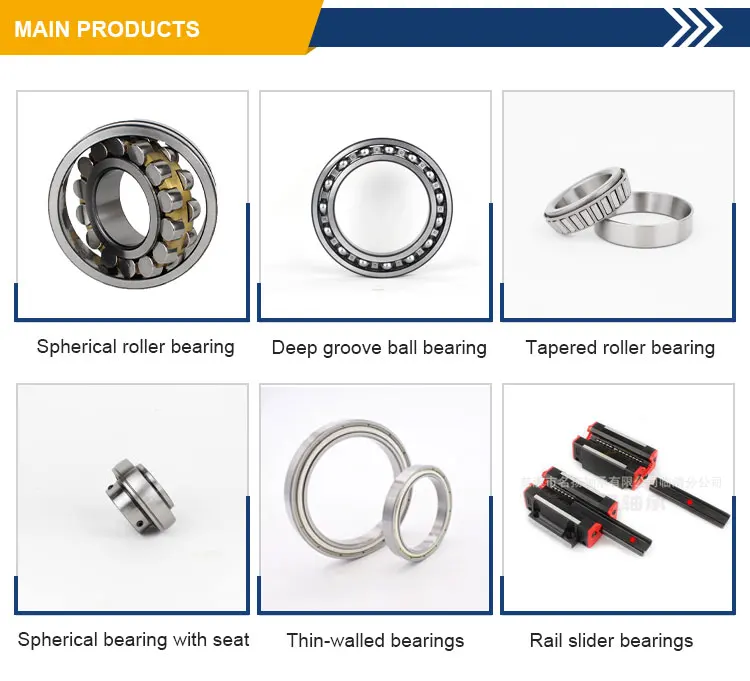

Main Products

Company Profile

Our main bearing products include Deep groove ball bearing,Thin wall deep groove ball bearings,Miniature bearings,Ceramic & stainless steel bearings,Angular contact ball bearing,Self-aligning ball bearing Cylindrical roller bearing Spherical roller bearing Tapered roller bearing,Thrust ball bearing,Thrust roller bearing,Spherical bearing with seat,Flange bearing,High temperature bearing,Guide rail & needle roller & slider bearing , and many non-standard bearings are also in our product range. The annual output is more than 10 million sets. To stay in front and making progress, we continually keep expanding our manufacturing capabilities in more cities where are more traffic-developed and Resources-adequate in Liaocheng,Ningbo and Tianjin in China. Our plant was equipped with fully modern enclosed dust-free workshop and warehouse, with improved detection technology. This enables us produce many high quality bearings and meet customers delivery time. All products could meet many advanced international standards with high quality steel and fully testing treatment.Quality Control MingKe has developed a comprehensive quality assurance program and quality system. This program and system establishes controls throughout the entire manufacturing cycle -from raw material purchasing and product manufacturing to end-item delivery. It also assures meeting quality objectives and minimizes the possibility of compromises which could affect product quality and reliability. The quality assurance program is complete and responsive to all requirements of ISO9001:2000.Our MissionWe are dedicated to providing our customers competitive price and excellent service.Our Values Customers - Our first priority is to increase our customer 's competitiveness in their markets by offering outstanding service,best price and products. We maintain strong and long-term relationships with our customers and focus our work on their total satisfaction. Integrity - We set high personal standards for ourselves and expect the people with whom we conduct business to do the same. In our company,we keep our promises. Speed - We know customers have urgent needs. We are skilled at effective communication to interact with customers. In order to provide prompt service,emails and instant message are widely used. People - We believe that our people are our greatest resource; therefore, we empower them, give them the opportunity to develop and grow.MingKe has been successful cooperation with many overseas customers, leaving good reputation of credibility with a high-quality product quality. With adequate resource, strict quality control, high-quality service, and competitive price, MingKe has been the first choice of many customers as bearing supplier. OEM is also welcomed as an optional cooperation method.

Packaging and Shipping

FAQ

Q1.Do you have MOQ?

Depends on different ideas, Can be negotiated.The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee,How much is it?

For the delivery fee,many samples are be requested to be sent,so we must get delivery fee.

If you tell me to use the appointed Express,you will give me your express account or you will pay according to the Express.

If you do not request,I will choose a cheap one in China.

Q3.How about the after sale service?

1)We will always keep the quality the same as the buyer's samples and if there is something with the quality,we will make compensation for our customers.

2)We will suggest our packing and take charge in our packing,we will keep the goods safe in the delivery.

3)We will trace the goods from the production to selling,we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

Depends on different ideas, Can be negotiated.The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee,How much is it?

For the delivery fee,many samples are be requested to be sent,so we must get delivery fee.

If you tell me to use the appointed Express,you will give me your express account or you will pay according to the Express.

If you do not request,I will choose a cheap one in China.

Q3.How about the after sale service?

1)We will always keep the quality the same as the buyer's samples and if there is something with the quality,we will make compensation for our customers.

2)We will suggest our packing and take charge in our packing,we will keep the goods safe in the delivery.

3)We will trace the goods from the production to selling,we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Похожие товары

Гибридный керамический подшипник HXHV 6902 abec 11

US $6.10-$6.30

HXHV Гибридный подшипник пресс. Велосипед

US $4.70-$5.40

HXHV оксид циркония полированный шаровой подшипник

US $4.80-$5.00