Оптовая продажа подшипник NF300 308 N NU NJ NF RN NUP RNU цилиндрический роликовый всех

- Категории: Cylindrical Roller Bearing >>>

- Поставщик: Mingke,International,Trade,(Shandong),Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Serve | OEM customization service |

Brand | Follow customer requirements |

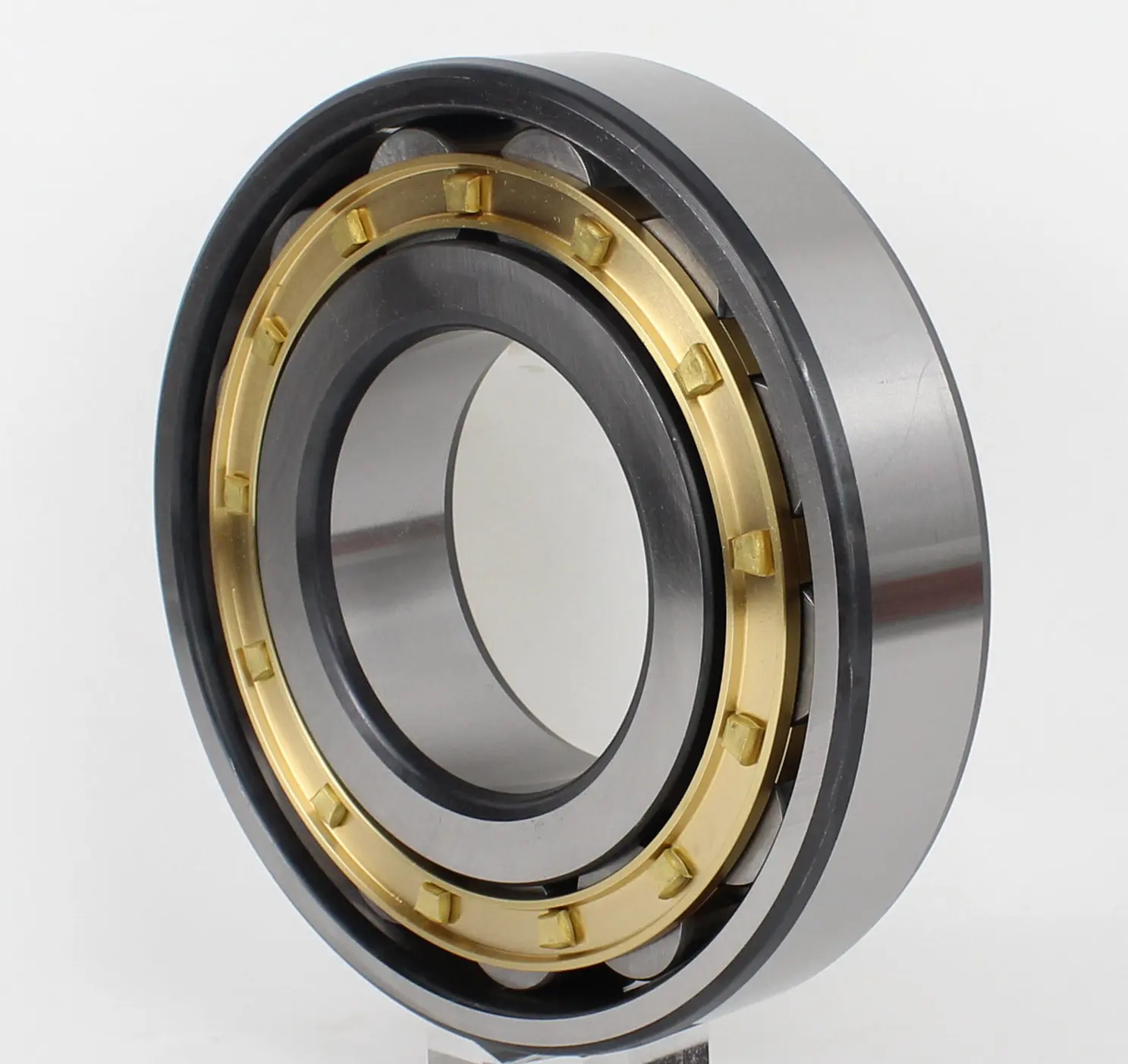

The rolling element is a radial rolling bearing of cylindrical rollers. The internal structure of the cylindrical roller bearing adopts the parallel arrangement of the rollers, and the spacers or spacers are installed between the rollers, which can prevent the inclination of the rollers or the friction between the rollers, and effectively prevent the increase of the rotation torque.

Cylindrical rollers and raceways are linear contact bearings. Load capacity, mainly bear radial load. The friction between the rolling element and the retaining edge of the ring is small, which is suitable for high-speed rotation. According to whether the ring has ribs, it can be divided into single row cylindrical roller bearings such as NU, NJ, NUP, N, NF, and double row cylindrical roller bearings such as NNU and NN. The bearing has a separable structure with inner ring and outer ring.

Cylindrical roller bearings with no ribs on the inner ring or outer ring, the inner ring and outer ring can move relative to the axial direction, so it can be used as a free end bearing. Cylindrical roller bearings with double ribs on one side of the inner ring and outer ring and a single rib on the other side of the ring can bear a certain degree of axial load in one direction. Generally, stamping steel cages or solid cages made of copper alloy cars are used. However, there is also a part of the use of polyamide forming cage.

1. The roller and the raceway are in line contact or repaired offline contact, with large radial bearing capacity, suitable for bearing heavy loads and impact loads.

2. The friction coefficient is small, suitable for high speed, and the limit speed is close to the deep groove ball bearing.

3. The N type and NU type can move axially, can adapt to the change of the relative position of the shaft and the housing caused by thermal expansion or installation error, and can be used as a free end support.

4. The processing requirements for the shaft or the seat hole are relatively high, and the relative deflection of the outer ring axis after the bearing is installed must be strictly controlled to avoid contact stress concentration.

5. The inner ring or outer ring can be separated for easy installation and disassembly

The cylindrical roller is in line contact with the raceway, and the radial load capacity is large. It is not only suitable for bearing heavy load and impact load, but also suitable for high-speed rotation.

The raceways and rolling elements of cylindrical roller bearings are geometrically shaped. After the improved design, it has a higher load carrying capacity. The new structural design of ribs and roller end faces not only improves the axial load carrying capacity of the bearing, but also improves the lubrication conditions of the contact area between the roller end face and the rib. The performance of the bearing.

Accuracy grade Cylindrical roller bearings can be divided into PO, P6, P5, P4, P2 according to the accuracy grade. The accuracy grades are sorted from low to high.

Application of large and medium-sized electric motors, locomotives, machine tool spindles, internal combustion engines, generators, gas turbines, reduction gear boxes, rolling mills, vibrating screens, and lifting and transporting machinery.

Product Show

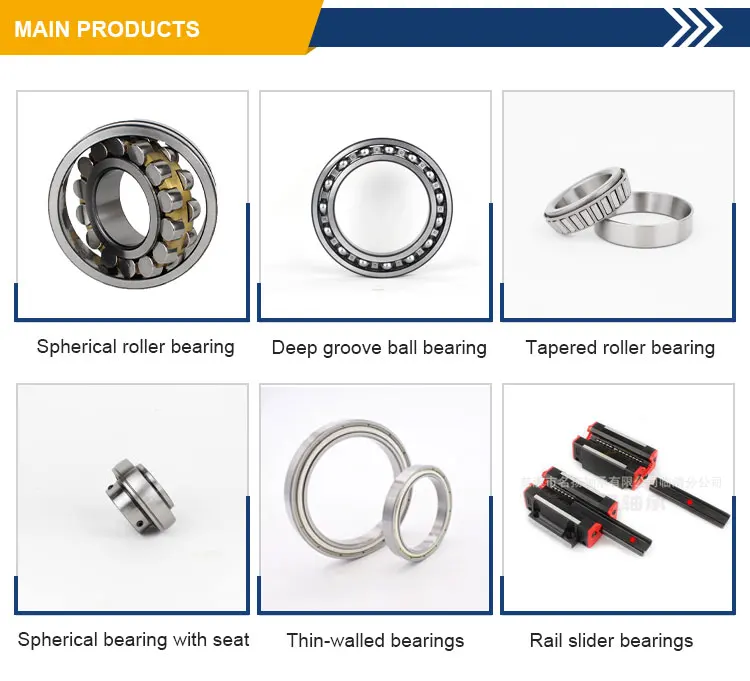

Main Products

Company Profile

Our main bearing products include Deep groove ball bearing,Thin wall deep groove ball bearings,Miniature bearings,Ceramic & stainless steel bearings,Angular contact ball bearing,Self-aligning ball bearing Cylindrical roller bearing Spherical roller bearing Tapered roller bearing,Thrust ball bearing,Thrust roller bearing,Spherical bearing with seat,Flange bearing,High temperature bearing,Guide rail & needle roller & slider bearing , and many non-standard bearings are also in our product range. The annual output is more than 10 million sets. To stay in front and making progress, we continually keep expanding our manufacturing capabilities in more cities where are more traffic-developed and Resources-adequate in Liaocheng,Ningbo and Tianjin in China. Our plant was equipped with fully modern enclosed dust-free workshop and warehouse, with improved detection technology. This enables us produce many high quality bearings and meet customers delivery time. All products could meet many advanced international standards with high quality steel and fully testing treatment.Quality Control MingKe has developed a comprehensive quality assurance program and quality system. This program and system establishes controls throughout the entire manufacturing cycle -from raw material purchasing and product manufacturing to end-item delivery. It also assures meeting quality objectives and minimizes the possibility of compromises which could affect product quality and reliability. The quality assurance program is complete and responsive to all requirements of ISO9001:2000.Our MissionWe are dedicated to providing our customers competitive price and excellent service.Our Values Customers - Our first priority is to increase our customer 's competitiveness in their markets by offering outstanding service,best price and products. We maintain strong and long-term relationships with our customers and focus our work on their total satisfaction. Integrity - We set high personal standards for ourselves and expect the people with whom we conduct business to do the same. In our company,we keep our promises. Speed - We know customers have urgent needs. We are skilled at effective communication to interact with customers. In order to provide prompt service,emails and instant message are widely used. People - We believe that our people are our greatest resource; therefore, we empower them, give them the opportunity to develop and grow.MingKe has been successful cooperation with many overseas customers, leaving good reputation of credibility with a high-quality product quality. With adequate resource, strict quality control, high-quality service, and competitive price, MingKe has been the first choice of many customers as bearing supplier. OEM is also welcomed as an optional cooperation method.

Packaging and Shipping

FAQ

Q1.Do you have MOQ?

Depends on different ideas, Can be negotiated.The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee,How much is it?

For the delivery fee,many samples are be requested to be sent,so we must get delivery fee.

If you tell me to use the appointed Express,you will give me your express account or you will pay according to the Express.

If you do not request,I will choose a cheap one in China.

Q3.How about the after sale service?

1)We will always keep the quality the same as the buyer's samples and if there is something with the quality,we will make compensation for our customers.

2)We will suggest our packing and take charge in our packing,we will keep the goods safe in the delivery.

3)We will trace the goods from the production to selling,we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

Похожие товары

Цилиндрические роликовые подшипники NF2316 NF2316ECM NF2316ECP

US $7.50-$10.00

Цилиндрический роликовый подшипник HXHV 8F3170 65x120x46 мм

US $1.00-$2.00

F57063 подшипник сплющенного ролика F-57063.RNU

US $15.00-$20.00

Цилиндрические роликовые подшипники NF2316 NF2316ECM NF2316ECP

US $7.50-$10.00