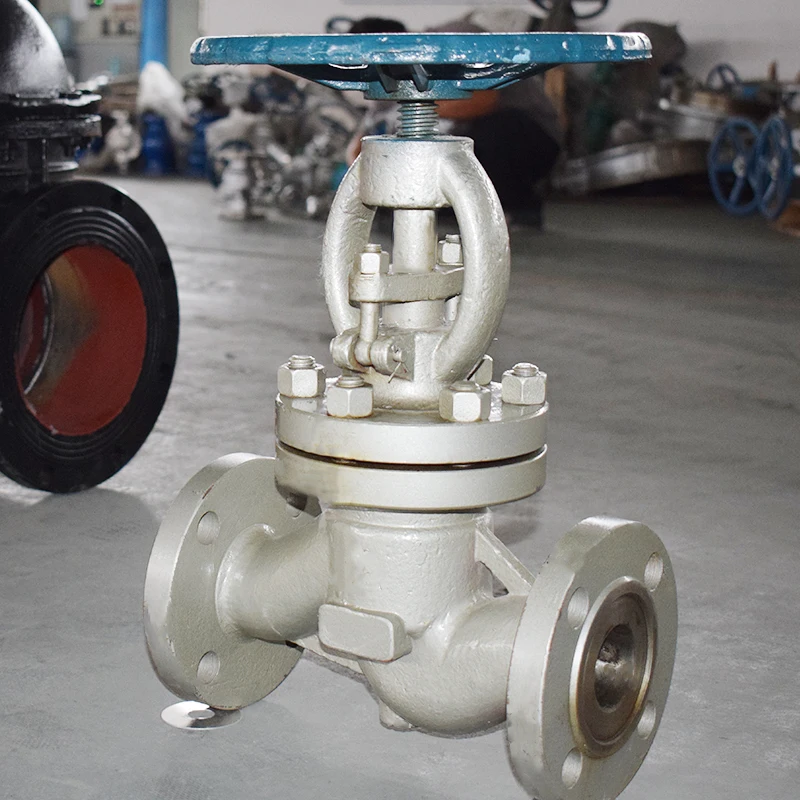

Ручной литой стальной 304/меховой шаровой клапан из высокопрочного чугуна с

- Категории: Manual Valves >>>

- Поставщик: KTEC,Fluid,Control,Equipment,(Tianjin),Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

| Product name | Globe valve |

| Model | Turbine |

| Size | DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 DN300 DN350 DN400 DN450 DN500 DN600 |

| Certification | ISO9001 |

| APPlication | petrochemical,electric power,metallurgy,menicine,real estate dan other industries. |

| Brand | KTEC |

| Pressure | PN10/PN16/150LB/JIS10K/JIS5K |

| Customized | OEM/ODM/OBM |

| Material | DI/WCB/SS304/SS316 |

| Tempearture | -20-90℃ |

| production process | investment casting,CNC lathe,Test,Cleaning,Packing,Storage |

| NO. | name | material |

| 1 | body | GS-C25,CF8,CF8M |

| 2 | seat | 13CR,SS304,SS316,stellite |

| 3 | disc | 13CR,SS304+stellite |

| 4 | pin | SS304,SS316 |

| 5 | Bellows components | SS304,SS316 |

| 6 | stem | 20CR13,F304,F316 |

| 7 | gasket | Flexible graphite + stainless steel, PTFE |

| 8 | cover | GS-C25,CF8,CF8M |

| 9 | Hexagonal nut | ASTM A 194-2H,A194-8 |

| 10 | Double nut | ASTM A 193-B7,A194-B8 |

| 11 | packing | Flexible graphite, PTFE |

| 12 | sleeve | 102S,SS304,SS3016 |

| 13 | Locating piece | 1025,WCB,CF8 |

| 14 | nut | Aluminum alloy,D2,BL-2 |

| 15 | handwheel | Carbon steel,KTH330 |

| 16 | And cap | A105 |

The valve features

The valve features

1. The key part of bellows globe valve is metal. The lower end and stem assembly are welded by automatic roll welding, and the upper end is welded by automatic roll welding with the connecting plate, forming a metal barrier between the fluid medium and the atmosphere to ensure that the stem has no leakage.

2. The valve disc adopts conical design, the sealing surface medium into streamline, better sealing performance, more durable.

3. Double sealing design (bellows + packing), stem packing will also avoid leakage, and meet the national sealing standards.

4. Grease fitting on bonnet provides direct lubrication of stem, nut and bushing, unlike traditional lubrication of thread only.

5. Ergonomic handwheel design, longer life, easy and convenient operation, more safe and reliable.

petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering, and other industries.

petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering, and other industries.