Wangli OEM сверхпрочная стальная Цементная Мельница и сахарная машина литье больших сегментов кольцевая

- Категории: Ring Gears >>>

- Поставщик: Luoyang,Wangli,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Why Choose Us

Products Description

Product Description

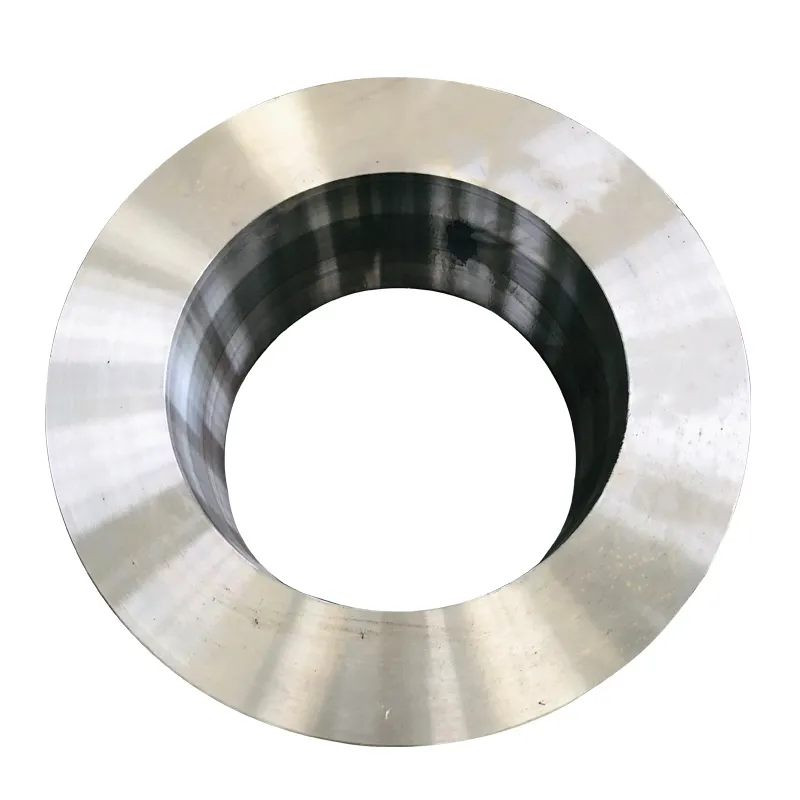

Product name: Wangli OEM Heavy duty alloy steel cement mill and sugar machinery casting large segments ring gear

We can produce large forging,casting and welding gears according to customer's drawings.According to the working conditions and clients' request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.

Some production process of Heavy duty alloy steel cement mill and sugar machinery casting large segments ring gear

According to the design structure and customer's requirement,the large gear ring can be produced by forging,casting and welding.

100% NDT TESTING

100% NDT testing including ultrasonic testing,magnetic testing.

By this way,we can test if there is any internal defect and control the raw material quality.

Heat treatment for casting large segments ring gear

If the gear module is large (above M25),we do the first time gear hobbing before heat treatment. According to this way,the gear teeth hardness depth after QT will be deeper,thus can improve the gear teeth mechanical property and can prolong the gear's service life.

Precision gear hobbing in 2-3 times to guarantee it's gear accuracy and surface roughness.Only in this way,the spur pinion gear can work well with the large ring gear or gear shaft.

When gear be finished.,we will provide our reports of raw material,hardness,size information to you.

We can manufacture different type of Ring gear according to the drawings

Our casting large segments ring gear is mainly used in the open-pit mining equipment.We also specialized on producing other spare part for large drgaline excavator,such as large module gears,gear shaft,upper and lower rail,coupling,sheave wheel/pulley,etc.

Related Products

About Us

Luoyang Wangli Heavy Machinery Co, LTD is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts, including shafts, gears, sprockets, sheaves, couplings, bearing supports, castings and forgings etc. The products are mainly used for fields ofg, petroleum, cement, steel mill, power plant, sugar factory etc. It has passed the certification of ISO9001-2008 in 2005.

We have different specifications of oil forging presses,ring rolling machines,electric arc furnaces,thus we can provide variety of forging,casting and welding materials according to customer's requests.

Advantage of our Heat Treatment:

- Professional, specific furnace, single-minded

- Vertical pit furnace,keep the temperature uniformity during heating,+/-1℃

- Small deformation,little oxide layer,reduce material cost

- Different materials can be cooled at the best speed

- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

- Vertical pit furnace,keep the temperature uniformity during heating,+/-1℃

- Small deformation,little oxide layer,reduce material cost

- Different materials can be cooled at the best speed

- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Machining

We have the completed machining equipment,including horizontal lathe,vertical lathe,CNC boring and milling machine,CNC boring machine,deep hole drilling and boring machine,gear hobbing machine,gear teeth grinding machine,grinding machine,etc.

Strictly quality inspection system can produce high quality products. Our quality certification system is ISO 9001:2015. For each order,we can provide report for material chemical components testing,UT testing,hardness,mechanical property testing(impact testing,yield strength testing,tensile strength testing),size inspection,etc.

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products.

R&D

We can provide technical support on new material,heat treatment and new manufacture process according customer’s working condition in order to improve lifespan of machinery parts.We have got a lot of patents on the spare parts of mill,cement rotary kiln,dragline excavator,rotor shafts.

Customer Visit

Our products have been exported to abroad for more than 10 years and 41 countries,such as America,Russia,Thailand,etc.

Похожие товары

Зубчатое кольцо, кольцо из нержавеющей стали, проектор от производителя

US $100.00-$10000

Прямая продажа с завода, шестеренка из нержавеющей стали

US $6.00-$7.00

Пластиковое кольцо с двойной шпорой, изготовленное на заказ

US $1.00-$10.00