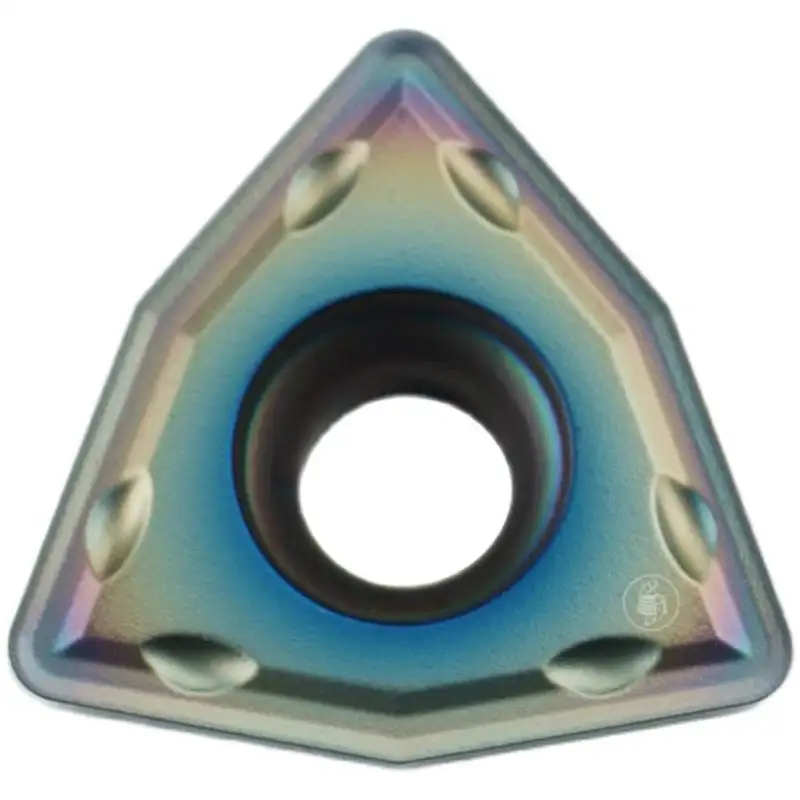

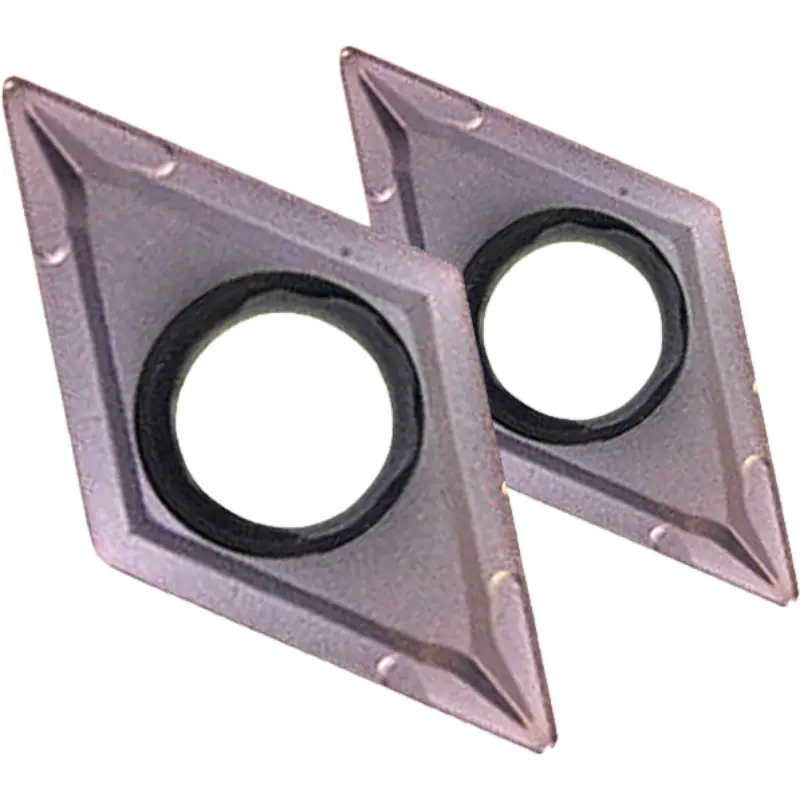

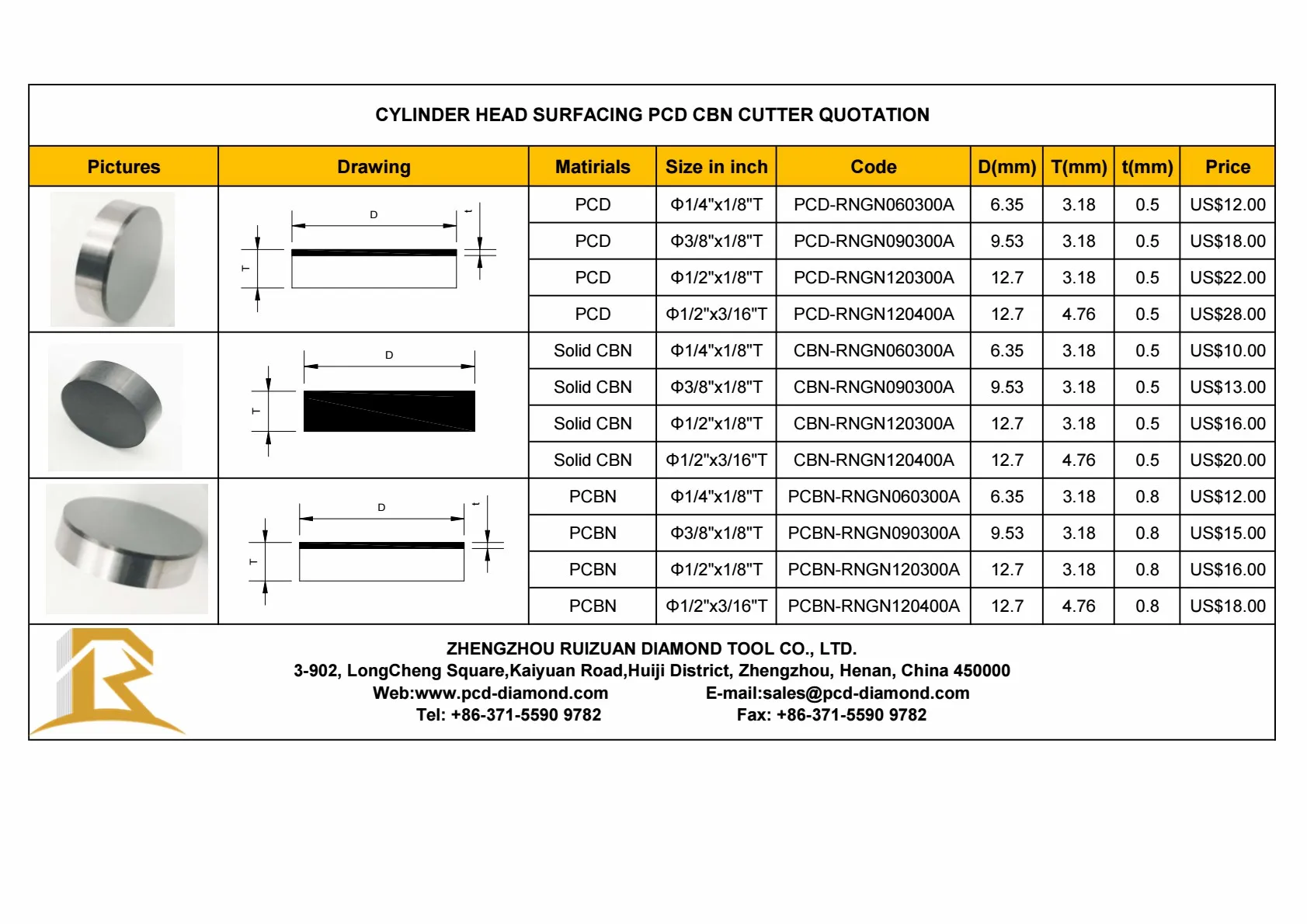

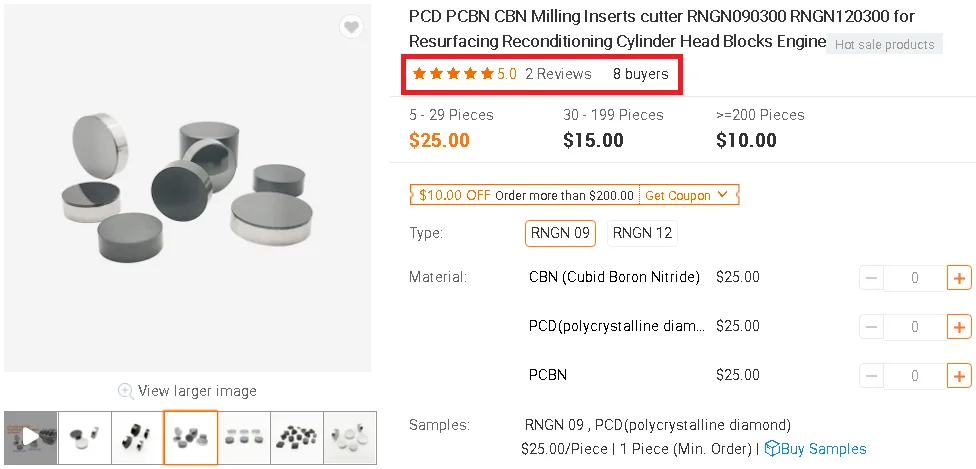

Резец сверхтвердый PCD CBN PCBN вставки карбида токарный инструмент держатель ЧПУ Токарный станок с для резки

- Категории: Turning Tool >>>

- Поставщик: Zhengzhou,Ruizuan,Diamond,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

标题

PCD PCBN inserts are widely used in processing pearlitic cast iron, high chromium and nickel alloy cast iron, hardened steel, powder metal, hard alloy and super alloy. In the mechanical machining application of the traditional system, not only it has greatly reduced the comprehensive production cost, but also significantly improved the production capacity and efficiency during the whole production operation, and the equipment investment is greatly decreased at the same time.

Poly Crystalline Diamond PCD cutter with carbide support

PCD the hardness and abrasion resistance of diamond with the impact resistance of tungsten carbide, and provides faster, more durable and more cost-effective drilling.

CBN cutters can be double-sided grinding and have a longer service life.

For Advantage of our PCD CBN cutter

1) Hight Abrasion resistant/High impact resistance

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

2)Easy to replace inserts.

3)All the cutting tools quality meet the ISO international standard.

4)Use orginal tungsten carbide material as basement.Using content of 99.95% or more high purity raw material, to ensure performance of PCD inserts basement.

5)Using box and carton packing, convenient for customer to handling.

Our Advantages

√ Excellent cost performance

The service life of PCD PCBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of PCD PCBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

√ High machining efficiency

The machining efficiency of PCD PCBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

√ Excellent surface quality

Surface finish and dimensional precision of machining workpiece of PCD PCBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

√ Strong universality

PCD PCBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

The service life of PCD PCBN insert can be more than 10 times that of carbide insert and reduce the cost of comprehensive cutting tool by 30%-50%. The interval time between the replacements of PCD PCBN insert is long and the insert replacement frequency is less, which can significantly reduce the cost on inserts.

√ High machining efficiency

The machining efficiency of PCD PCBN insert is 5-10 times that of the carbide insert, which greatly improves the equipment capacity and reduces the fixed investment of equipment.

√ Excellent surface quality

Surface finish and dimensional precision of machining workpiece of PCD PCBN insert can reach the grinding level, and make turning instead of grinding to reduce equipment investment.

√ Strong universality

PCD PCBN insert can be used for both dry cutting and wet cutting and one grade normally is suitable for machining a variety of materials.

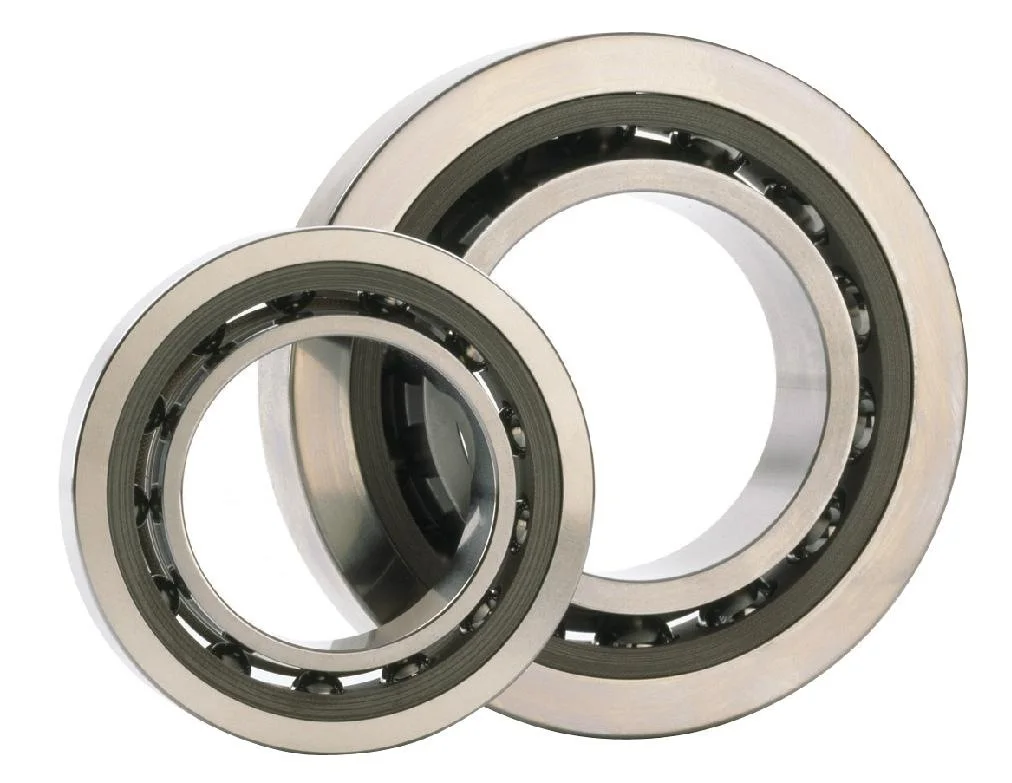

Application

For turning and milling of cylinder blocks and heads, centrifugal rolls, slurry pumps, brake discs, brake drums, rolling mortar walls, compressor parts, gears, bearings, mining machinery, coal mining machinery industries.

Customer Reviews

Why Choose Us

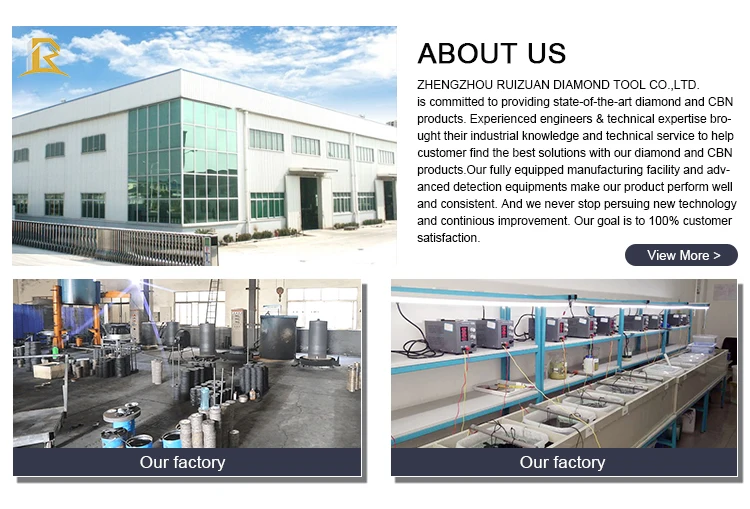

Company Profile

Our Equipments

8 Press machines

3 Lathe machines

2 Blance machines

2 Vollmer QWD760 EDM Cutting

2 Ewag CNC grinding machines

1 Zoller Inspections machines

1 Optical Projector

1 Drilling machines

3 Lathe machines

2 Blance machines

2 Vollmer QWD760 EDM Cutting

2 Ewag CNC grinding machines

1 Zoller Inspections machines

1 Optical Projector

1 Drilling machines

Packing & Delivery

Packaging | ||

Size | 100 (L) * 50 (W) * 8mm (D) | |

Weight | 0.1KG | |

Packaging Details | The normal package is Plastic box. Sizes: 100x50x8mm 140x60x10mm | |

DELIVERY TIME:

3-30 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

3-30 days after confirming order,detail delivery date should be decided according to

production season and order quantity.