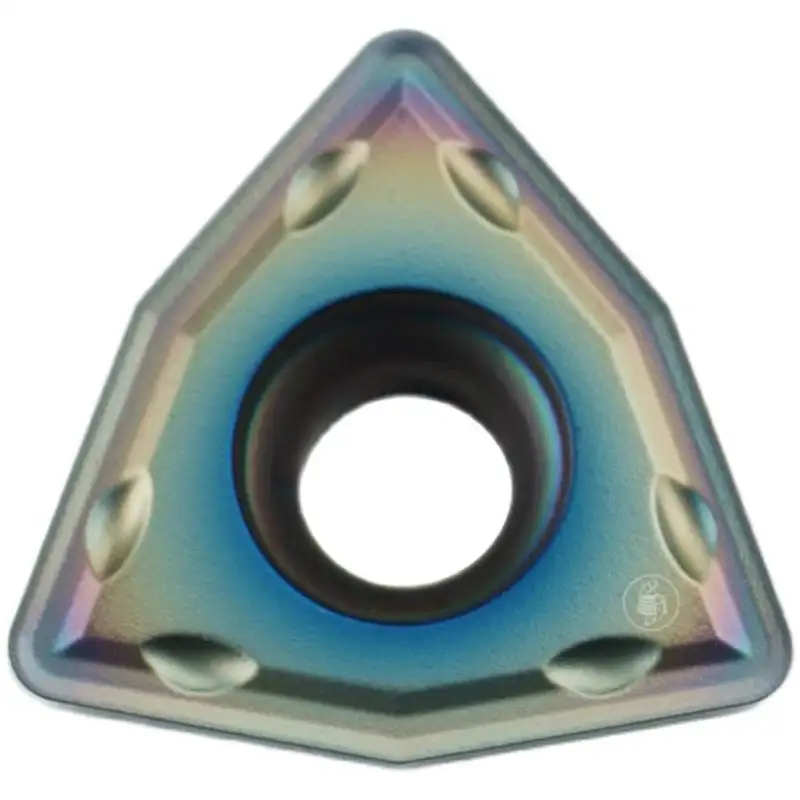

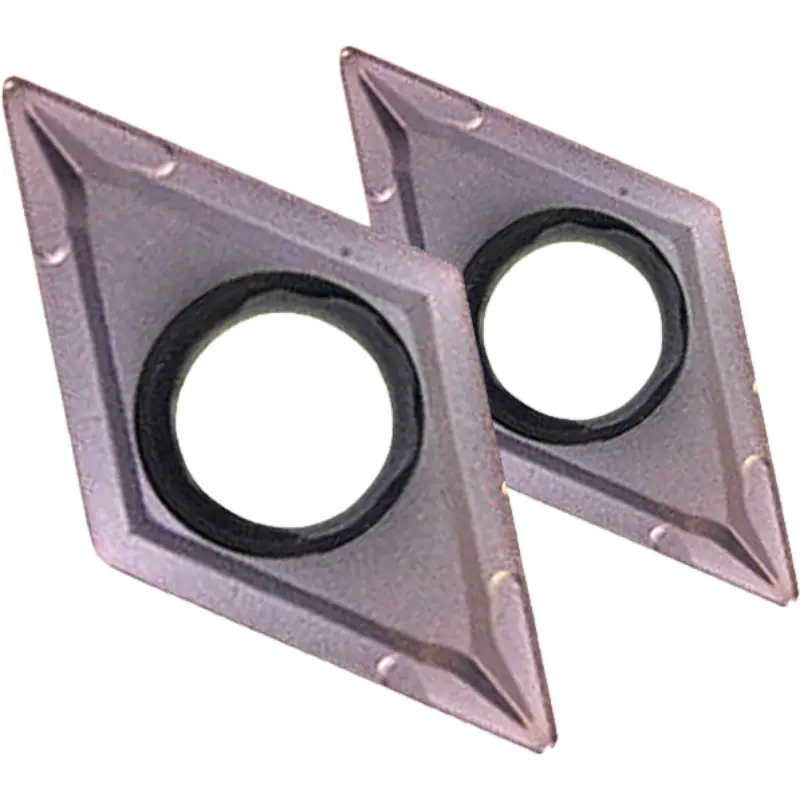

metal cutting carbide inserts factory YT5 C122 C107 brazed tool YT15 C125 C109 tungsten cemented tips for lathe

- Категории: Turning Tool >>>

- Поставщик: Qinghe,Xingzuan,Cemented,Carbide,Factory

Поделиться:

Описание и отзывы

Характеристики

cemented carbide inserts and their applications recommended

| ISO Code | Grade | Applications recommended |

| P10 | YT15 | It is suitable for semi-finishing of steel and casting steel machining, high cutting speed, medium feed rate is recommended. |

| P20 | YT14 | It is suitable for semi-finishing of steel and casting steel. |

| P30 | YT5 | Suitable for the heavy duty rough turning of steel and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

| M10 | YW1 | It is suitable for semi-finishing of stainless steel and general alloy steel machining. |

| M20 | YW2 | It is suitable for semi-finishing and light roughing of stainless steel and alloy steel. |

| M30 | YS25 | It is used for milling machining of stainless steel, steel and casting steel. |

| M30 | YS30 | It is suitable for semi-finifishing and light roghing of stainless steel and alloy steel. |

| K20 | YG6 | It is suitable for light roughing and semi- finishing of casting iron, nonferrous metal, heat-resistance alloy and Ti alloy. |

| K20 | YG8 | It is suitable for semi-finishing and roughing of casting iron, nonferrous metal, heat- resistance alloy and Ti alloy at continuous and intermittent machining conditions. |

Qinghe Xingzuan Cemented Carbide Factory is a company engaged in the research, development, production and sales of carbide indexable inserts and cutting tools. The company has a modern industrial production standard factory building and advanced cemented carbide production equipment, and is a high-tech enterprise with complete production technology, technical equipment and production quality control means in the cemented carbide industry. The company adheres to the quality policy of "quality first, customer first, scientific and technological innovation, striving for first class", establishes a quality management system in strict accordance with GB/T 19001-ISO 9001 international quality standards, strictly controls the production process and product quality, provides customers with products with satisfactory price/performance ratio, takes customer needs as the goal, strives to develop new products, meets changing market demands, takes "maximization of customer interests" as the goal, and insists on creating common ownership.

All our products are inspected strictly

Product production equipment

Our products have a large inventory to ensure delivery speed

1:Where is your factory located?

Our factory is located in Qinghe County, Xingtai City, Hebei Province, China