GW-9101 Digital Alternating Winding

- Категории: Electric Equipment Making Machinery >>>

- Поставщик: Tianjin,Grewin,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

GW-9101 Digital Alternating Winding Machine

Model | GW-9101 | Spindle | 1 |

Wire diameter | 0.02-1.5 | Spindle motor | 300W/DC |

Wire spacing | 0-9.999MM | Max. speed | 3600-6000RPM |

Spreading Motor | Stepper motor | Size | 700*500*700 |

Power supply | AC 220V 50/60HZ | Weight | 55 |

FEATURES:

Digital Alternating Winding Machine adopt microcomputer controller, easy to set data

The wireline shaft is driven by a stepping motor with a constant current circuit, with fast wireline speed and high precision

Wound circular arc products (hollow arc and solid arc can be wound)

The maximum arc is less than 180 degrees

The Digital Alternating Winding Machine point, width, line distance and speed can be set in sections to achieve the purpose of multi-section and multi-speed

Digital Alternating Winding Machine can set 999 step sequence, and can store the set value for more than one year

ADVANTAGES:

Digital Alternating Winding Machine to meet the requirements of high efficiency and high output.

Fully automatic machines are generally designed with multi-head linkage, and most domestic manufacturers refer to the design of imported models from Taiwan and other places.

The programmable controller is used as the control core of the equipment, with the manipulator, pneumatic control components and execution accessories to complete the functions of automatic wire arrangement, automatic foot winding, automatic wire cutting,

automatic loading and unloading skeleton, etc.

Ring winding machine this type of production efficiency is very high, greatly reduce the reliance on artificial, an operator can take care of several such equipment at the same time, the production quality is relatively stable, very suitable for production requirements of high processing occasions.

APPLICATION:

Automatic Coil winding Machines are used for winding the small EI transformers, signal transformers, inductors, filter choke coil,

relays, current contactors, valve coils, solenoid coils, telecom bobbin transformers. It can complete the coils without any one

operator in fully automatically.

Digital Alternating Winding Machine adopt microcomputer controller, easy to set data

The wireline shaft is driven by a stepping motor with a constant current circuit, with fast wireline speed and high precision

Wound circular arc products (hollow arc and solid arc can be wound)

The maximum arc is less than 180 degrees

The Digital Alternating Winding Machine point, width, line distance and speed can be set in sections to achieve the purpose of multi-section and multi-speed

Digital Alternating Winding Machine can set 999 step sequence, and can store the set value for more than one year

ADVANTAGES:

Digital Alternating Winding Machine to meet the requirements of high efficiency and high output.

Fully automatic machines are generally designed with multi-head linkage, and most domestic manufacturers refer to the design of imported models from Taiwan and other places.

The programmable controller is used as the control core of the equipment, with the manipulator, pneumatic control components and execution accessories to complete the functions of automatic wire arrangement, automatic foot winding, automatic wire cutting,

automatic loading and unloading skeleton, etc.

Ring winding machine this type of production efficiency is very high, greatly reduce the reliance on artificial, an operator can take care of several such equipment at the same time, the production quality is relatively stable, very suitable for production requirements of high processing occasions.

APPLICATION:

Automatic Coil winding Machines are used for winding the small EI transformers, signal transformers, inductors, filter choke coil,

relays, current contactors, valve coils, solenoid coils, telecom bobbin transformers. It can complete the coils without any one

operator in fully automatically.

Company related products:

GWM-0319 Automatic Gear Toroidal Winding Machine | ||||||

Wire diameter | 0.60—1.60 | Max.winding speed | 200rpm | |||

Max.final coil.O.D | φ60—200 | Wire spacing | Proportional linkage | |||

Min.final coil.I.D | φ30 | Supply voltage | AC 220V(50Hz) | |||

Max.finalcoil height | 80 | Mechanical dimensions | 550×500×750 | |||

Controller storage capacity Programs | 29 set | Wdight | 94kg | |||

GWM-0719 Toroidal Transformer Winding Machine | ||||||

Wire diameter | 1.0—4.50 | Max.winding speed | 150rpm | |||

Max.final coil.O.D | φ250—800 | Wire spacing | Proportional linkage | |||

Min.final coil.I.D | φ80 | Supply voltage | AC 220V(50Hz) | |||

Max.finalcoil height | 250 | Mechanical dimensions | 1050x900x1530mm | |||

Controller storage capacity Programs | 29 set | Wdight | 383kg | |||

GWM-0519 Current Transformer Winding Machine | ||||||

Wire diameter | 0.50—1.60 | Max.winding speed | 200rpm | |||

Max.final coil.O.D | φ65—430、φ55 | Wire spacing | Proportional linkage | |||

Min.final coil.I.D | φ45-385、φ35 | Supply voltage | AC 220V(50Hz) | |||

Max.finalcoil height | 60 | Mechanical dimensions | 1000×950×750 | |||

Controller storage capacity Programs | 29 set | Wdight | 100kg | |||

GWM-0319B Toroid Transformer Winding Machine | ||||||

Wire diameter | 0.50—1.30 | Max.winding speed | 200rpm | |||

Max.final coil.O.D | φ60—200 | Wire spacing | Proportional linkage | |||

Min.final coil.I.D | φ25 | Supply voltage | AC 220V(50Hz) | |||

Max.finalcoil height | 80 | Mechanical dimensions | 550×500×750 | |||

Controller storage capacity Programs | 29 set | Weight | 94kg | |||

GWM-0519 Current Transformer Winding Machine | ||||||

Wire diameter | 0.50—1.60 | Max.winding speed | 200rpm | |||

Max.final coil.O.D | φ65—430、φ55 | Wire spacing | Proportional linkage | |||

Min.final coil.I.D | φ45-385、φ35 | Supply voltage | AC 220V(50Hz) | |||

Max.finalcoil height | 60 | Mechanical dimensions | 1000×950×750 | |||

Controller storage capacity Programs | 29 set | Wdight | 100kg | |||

GWM-0719 Made in China and exported to Europe, large-scale CNC gear head large-diameter winding machine

ADVANTAGES:

A short period of delivery:10 days after payment

Wide range of application, Large range of Speed adjustment, wide range of the wire diameter, Multi-style of core, Brake tension

adjustable, Good settlement for large outer diameter, small inner diameter, heavy wire coils.

High production efficiency, increase winding efficiency by adjustment of suitable brake tension,

Each wiring part guarantee no wire damage.

Free replacement of mainframe accessories

The technicians are experienced

A short period of delivery:10 days after payment

Wide range of application, Large range of Speed adjustment, wide range of the wire diameter, Multi-style of core, Brake tension

adjustable, Good settlement for large outer diameter, small inner diameter, heavy wire coils.

High production efficiency, increase winding efficiency by adjustment of suitable brake tension,

Each wiring part guarantee no wire damage.

Free replacement of mainframe accessories

The technicians are experienced

Parallel Winding Machine

GW-9761

High Speed Parallel Winding Machine has microprocessor design ,easy for program-setting handing

GW-9762

High Speed Automatic Coil Winding Machine has microprocessor design ,easy for program-setting handing.

Spindle Coil Winding Machine

Why choose GREWIN INDUSTRIAL GROUP CO.,LTD:

Following are our strong advantages:

1.We provide you the friendly English User manual or operating videos for free.

2.24 hours technical support by email or calling.

3.Warranty: 1 year free, 2-3 years cost price and free technical support always.

4.Free training to make sure you master the operating of our products.

5. OEM/ODM accept . But the MOQ of OEM/ODM is 100 sets.

Service tenet

Provide you the best service with "fast + satisfactory + safe".

Warranty period:

12 months long after the user received the product.

Warranty items:

Only for abnormal breakdown caused by the machine design or manufacture defect,free repair and accessory will be provided.

Technology service ability:

All service engineers with many years experience are gotten special technology training, who can deal with various breakdown problem.

Guide the user to use accurately and how to maintain the product.

Provide free consultation about production process technology of electronic products.

Service after sell:

In order to guarantee the machine used normally, we'd have training on how to operate, use and maintain our product by English

manual, video, guiding on line.

Use instruction:

Apply for the right complete size of product, otherwise, the wrong dimensions will affect the use effect.

Do ensure using the product accord to the use instruction completely.Do not exceed the scope of application of the products.

Maintain the product after use,Damp proof, rust proof, leak proof, explosion-proof, regular maintenance and inspection should be taken care. All done help to extend the use period.

1.We provide you the friendly English User manual or operating videos for free.

2.24 hours technical support by email or calling.

3.Warranty: 1 year free, 2-3 years cost price and free technical support always.

4.Free training to make sure you master the operating of our products.

5. OEM/ODM accept . But the MOQ of OEM/ODM is 100 sets.

Service tenet

Provide you the best service with "fast + satisfactory + safe".

Warranty period:

12 months long after the user received the product.

Warranty items:

Only for abnormal breakdown caused by the machine design or manufacture defect,free repair and accessory will be provided.

Technology service ability:

All service engineers with many years experience are gotten special technology training, who can deal with various breakdown problem.

Guide the user to use accurately and how to maintain the product.

Provide free consultation about production process technology of electronic products.

Service after sell:

In order to guarantee the machine used normally, we'd have training on how to operate, use and maintain our product by English

manual, video, guiding on line.

Use instruction:

Apply for the right complete size of product, otherwise, the wrong dimensions will affect the use effect.

Do ensure using the product accord to the use instruction completely.Do not exceed the scope of application of the products.

Maintain the product after use,Damp proof, rust proof, leak proof, explosion-proof, regular maintenance and inspection should be taken care. All done help to extend the use period.

Product packing:

Wooden case package: For larger scale goods as machine equipment etc, we have special skilled carpenter, who would make the proper wooden case with exact thickness,density,length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent crack and shock. We will inform you the delivery note. You just need to wait for phone call, then pick up the goods at the nearest logistic station .(Please let me know in advance if you want get the goods at home.)

Packaging:

Packaging material: Carton/Wooden case with foam inside.

Packaging:

Packaging material: Carton/Wooden case with foam inside.

FAQ:

1) This is the first time I use this kind of machine, is it easy to operate?There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea

Company introduction information:

GREWIN INDUSTRIAL GROUP CO.,LTD is a leading manufacturer of toroidal coll winding equipment. The program includes machines for winding toroidal power transformers, current transformers El coil, inductors and variable voltage transfomers, as well as toroidal taping machines, toroidal winding transformer tester.

Always alming towards improving quality and performance a highly qualified research and design team and the most advanced manufacturing equipment secure a long life and dependability of all GREWIN products, Many features of the equipment are covered by Chinese and foreign patents. contributing to its reputation for the highest productivity in today's tough work environment.

Always alming towards improving quality and performance a highly qualified research and design team and the most advanced manufacturing equipment secure a long life and dependability of all GREWIN products, Many features of the equipment are covered by Chinese and foreign patents. contributing to its reputation for the highest productivity in today's tough work environment.

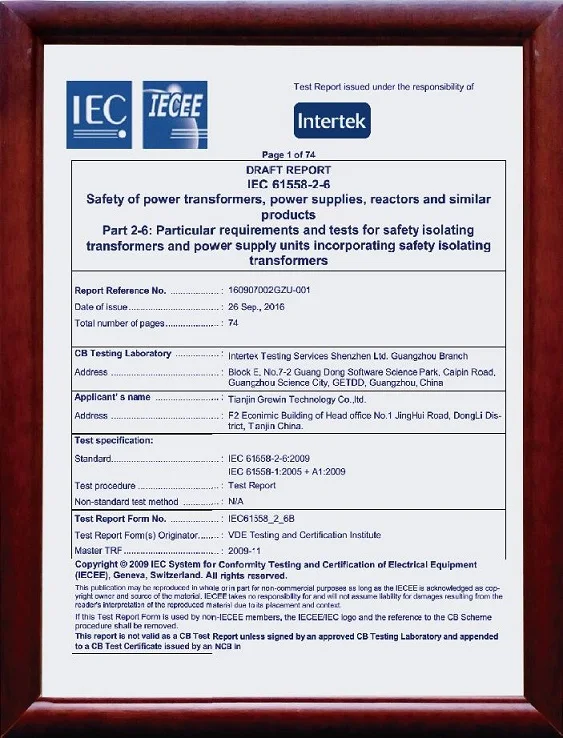

Top quality is assured according to the IEC ISO 9001 standard system, Products are subjected to a strict testing program

before they are released to customers, and we offer an extensive warranty and after sales service including easy access to

replacement parts; directly or through our network of distributors. Excellent service has helped make our products known all over Southeast Asia and Europe and boosted sales in many other markets.

before they are released to customers, and we offer an extensive warranty and after sales service including easy access to

replacement parts; directly or through our network of distributors. Excellent service has helped make our products known all over Southeast Asia and Europe and boosted sales in many other markets.

Certification

Contact us

Clara NI

GREWIN INDUSTRIAL GROUP CO.,LTD

Add:The Fouth Floor A-A3 Zone Aviation Business Area,DongLi Distrct,Tianjin China

Tianjin | 300222 | China

Mail:sales1@coilwindingmachinechina.com

Web:www.coilwindingmachinechina.com

Mobile/WhatsApp: +86 18622096679

TEL: +86 (22) 84943756 | Skype:lialice99

GREWIN INDUSTRIAL GROUP CO.,LTD

Add:The Fouth Floor A-A3 Zone Aviation Business Area,DongLi Distrct,Tianjin China

Tianjin | 300222 | China

Mail:sales1@coilwindingmachinechina.com

Web:www.coilwindingmachinechina.com

Mobile/WhatsApp: +86 18622096679

TEL: +86 (22) 84943756 | Skype:lialice99

Похожие товары

Автоматическая Большая тороидальная машина для намотки

US $2380-$2800

Автоматическая машина для намотки якоря с крючком

US $2800-$3280