630mm PP plate industrial dehydration chamber filter press export to

- Категории: Filter Press Equipment >>>

- Поставщик: Zhengzhou,Toper,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

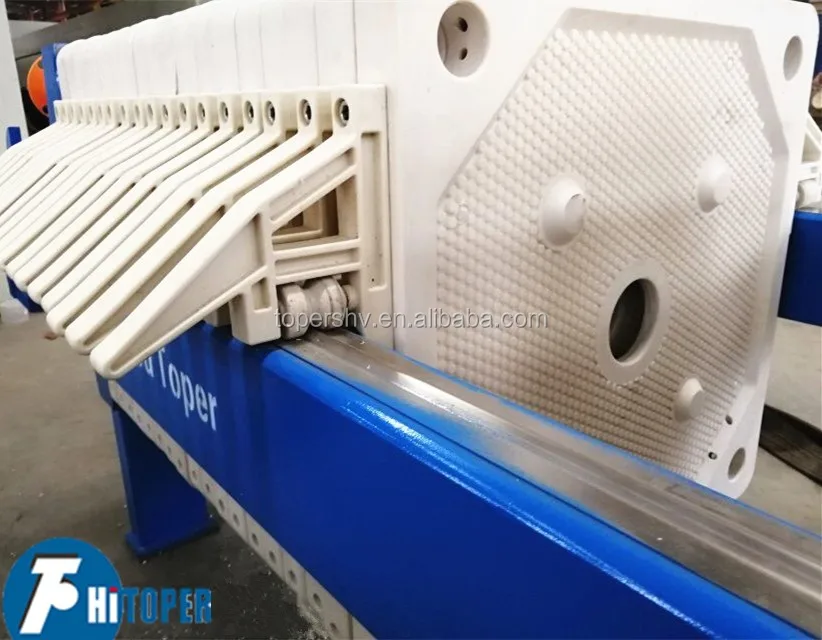

630mm PP plate industrial dehydration chamber filter press export to Mexico

SPECIFICATIONS OF PP PLATE CHAMBER FILTER PRESS ----PP PLATE INDUSTRIAL DEHYDRATION FILTER | ||||||

Working principle of the 630mm PP plate industrial dehydration chamber filter press

When the filter press is suitable installation, you can push the power button ,and the pressing process is start as the machine is automatically controled :

The cylinder piston of hydraulic device drives the push plate to press the filter plate and filter cloth between push plate and tail plate.Filter chamber are formed between pressed filter plates and materials get into the filter chamber through the inlet of tail plate with the help of feeding pump.

Solid particles are remainned in filter chambers forming into cakes ,while liquid is discharged out of the machine through press cake and filter cloth.

To wash the press cakes,washing water can be introduced through the washing inlet of the tail plate.

1.Hydraulic station

1.11Hydraulic unit, carbon steel bending welding and sealing.

A.Air filters external oil pumps of Shanghai Dazhong brand, with a better cooling effect and easy maintenance

B.Hydraulic valves of Shanghai Huadao brand.

C.High pressure oil pipe (36Mpa, 1.5m) and low pressure oil pipe (22.4Mpa, 2m), China standard soft connection.

1.12 Hydraulic cylinder, welded using material 27SiMn seamless steel pipe, Inner diameter and stroke is Φ120X400, pressing pressure is 18-20MPa.

1.13 Piston rod, Medium-frequency hardening with 45# steel, the surface hardness can be HRC48-50, and there is a protect cover outside.

2.Main Beam

Material of high quality carbon steel Q345 ( Length & width & thickness, 120×60×6mm rectangular tube), box welded structural design, automatic submerged arc welding process with weld smooth and beautiful. Still processed with sand blasting to remove rust and oxide skin, then painted by epoxy primer to get higher intensity and corrosion resistance, together with last protection of acrylic polyester anti-corrosion paint spraying.

3.Filter plate

3.11 Polypropylene(PP) with acid & alkali resistance, anticorrosion, innocuity, tasteless, light weight and high strength, producing by using 5000 tons high-pressure compressor, every plates before delivery is tested under high pressure 27MPa.

3.12 External size is 505*505mm, inner size is 450*450mm, thickness is 65mm, and weight is 8.5kg.

4.Control cabinet

The cover is carbon steel with spray with button operation, Chinese famous brand inverter and electronic components. Also as you need we can provide you with PLC control, Delta inverter and Schneider electronic components, more extra fees will be needed with your actual situation.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging for main machine | ||

Size | 4000x1000x1200mm | |

Weight | 2000kgs | |

Packaging Details | The normal package for the main filter press machine is shrink-wrapped, we can also provide export plywood case package or other export package | |

Packaging for matched parts | ||

Size | 560(L) * 455 (W) * 710(D) | |

Weight | 35kgs | |

Packaging Details | The normal package for the hydraulic station or filter cloth or oil pipes or open flow taps or feeding pump is export wooden case | |

Chamber filter press of automatic discharging cake type

Membrane filter press of automatic discharging cake type

Round plate filter press