oil tank welding machine automatic girth for Horizontal Circumference Welding

- Категории: Seam Welders >>>

- Поставщик: Shandong,Shuipo,Welding,&,Cutting,Equipment,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

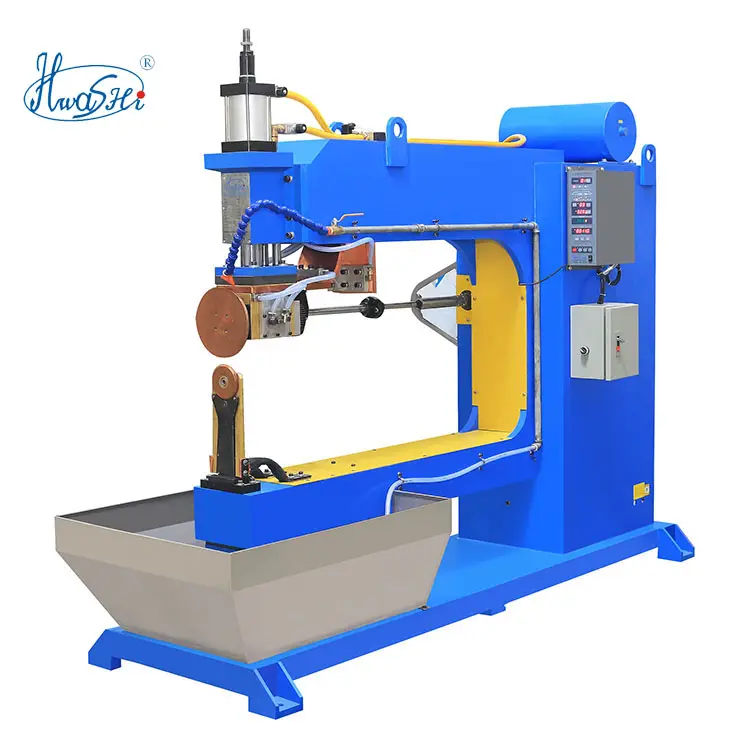

oil tank welding machine automatic girth welding machine for tank Horizontal Circumference Welding Machine

1.Pictures for oil tank welding machine automatic girth welding machine for tank Horizontal Circumference Welding Machine

2.Introduction of oil tank welding machine automatic girth welding machine for tank Horizontal Circumference Welding Machine

(1)Advanced computer controlling technology

(2)PLC technology

(3)Micro-electronics and the frequency conversion technology

(4)Welding seams are good in appearance, high in welding quality and production efficiency, simple and convenient in operation, which has improved both the efficiency and quality.

(Note: Can be customized according to clients' requirements.)

(Working in clients' workshop)

( Shapes of Workpiece

( Shapes of Workpiece

3.Technical Statistics of oil tank welding machine automatic girth welding machine for tank Horizontal Circumference Welding Machine

Maximum Diameter | 3000mm (can be customized) | |

Minimum Diameter | 1200mm | |

Gantry | Gauge | 3600mm |

Rail Length | 16000mm (can be customized) | |

Rotating Device | Gauge | 1200mm |

Rail Length | 16000mm | |

Welding Speed | 50-600mm/min | |

Gantry Longitudinal Returning Speed | 2800mm/min | |

Welding position | flat position welding | |

Welding Wire Diameter | 1.2-1.6mm | |

Welding Manner | Submerged Arc Welding, or MIG Welding | |

Gantry Drive | AC Frequency Converter, Stepless Speed Regulation, Double Sides Drive | |

Rotating Device Drive | The AC Frequency Converter, the Stepless Speed Regulation | |

Cable Conveying | The Tackle Type | |

Flux Reclaimer | The Pneumatic Automatic | |

Welding Profile Modeling | Magnetic Automatic Profile Modeling | |

Welding Width | 5-12mm | |

Welding Seam Monitoring Mode | The Guide Track | |

Power Supply | AC 380V 50HZ 3-phase 4-wire | |

Main Machine Power Supply | 31KW | |

4.Main configuration of oil tank welding machine automatic girth welding machine for tank Horizontal Circumference Welding Machine

| Name | Brand | |||||

| Power source | Fronius TPS 5000 | |||||

| PLC | Mitsubishi | |||||

| AC Frequency | Delta | |||||

| Servo motor | Panasonic | |||||

| Button | Schneider | |||||

| Contactor | Schneider | |||||

| Breaker | Schneider | |||||

| Relay | Omron | |||||

5.More products for your choose

1.About us

Shandong Shuipo Welding & Cutting Equipment Manufacture Co., Ltd. focuses on the

research and manufacture of welding and cutting equipment for cars, modified trailers,

special purpose vehicles, and the industry of construction machinery, shipbuilding and

steel structure. Our company covers an area of 42,000 square meters, including 12,000

square meters of construction area. The registered capital of our company reaches

10 million Yuan and our total asset reaches 60 million Yuan.

2.Package

3.Our Market

| Main Markets: | South Asia |

| North America | |

| South America | |

| Mid East | |

| Southeast Asia | |

| Africa | |

| Eastern Europe | |

| Western Europe | |

| Total Annual Sales Volume: | US$50 Million - US$100Million |

| Export Percentage: | 31% - 40% |

4.Contact

FAQ

1. Why choose us?

We are manufacturer with more than 16 years experience ,can provide the high quality ,efficiency and precision machines , competitive price and good after-sale service.

Markets:70% chinese market , exported more than 60 countries and areas,receiving many good reputation.

2.What certifications you have ?

CE certifications and ISO certifications

3.What services you can offer ?

(1) Warranty of machine for one year .

(2) Engineers available to service machinery overseas

(3) Free customers training in our plant.

(4)English manual and video for machine instruction and maintenance.

(5)OEM,ODM is available in our factory.