MXK3821A Wooking длина 2100 мм двухсторонний шипорезный станок/двухсторонний для

- Категории: Mortising Machines >>>

- Поставщик: Hangzhou,Smart,Panther,Tech,Ltd.

Поделиться:

Описание и отзывы

Характеристики

MXK3821A Wooking Length 2100mm CNC Double-end Tenoning Machine /double Sided Tenoner For Sale

Product Description

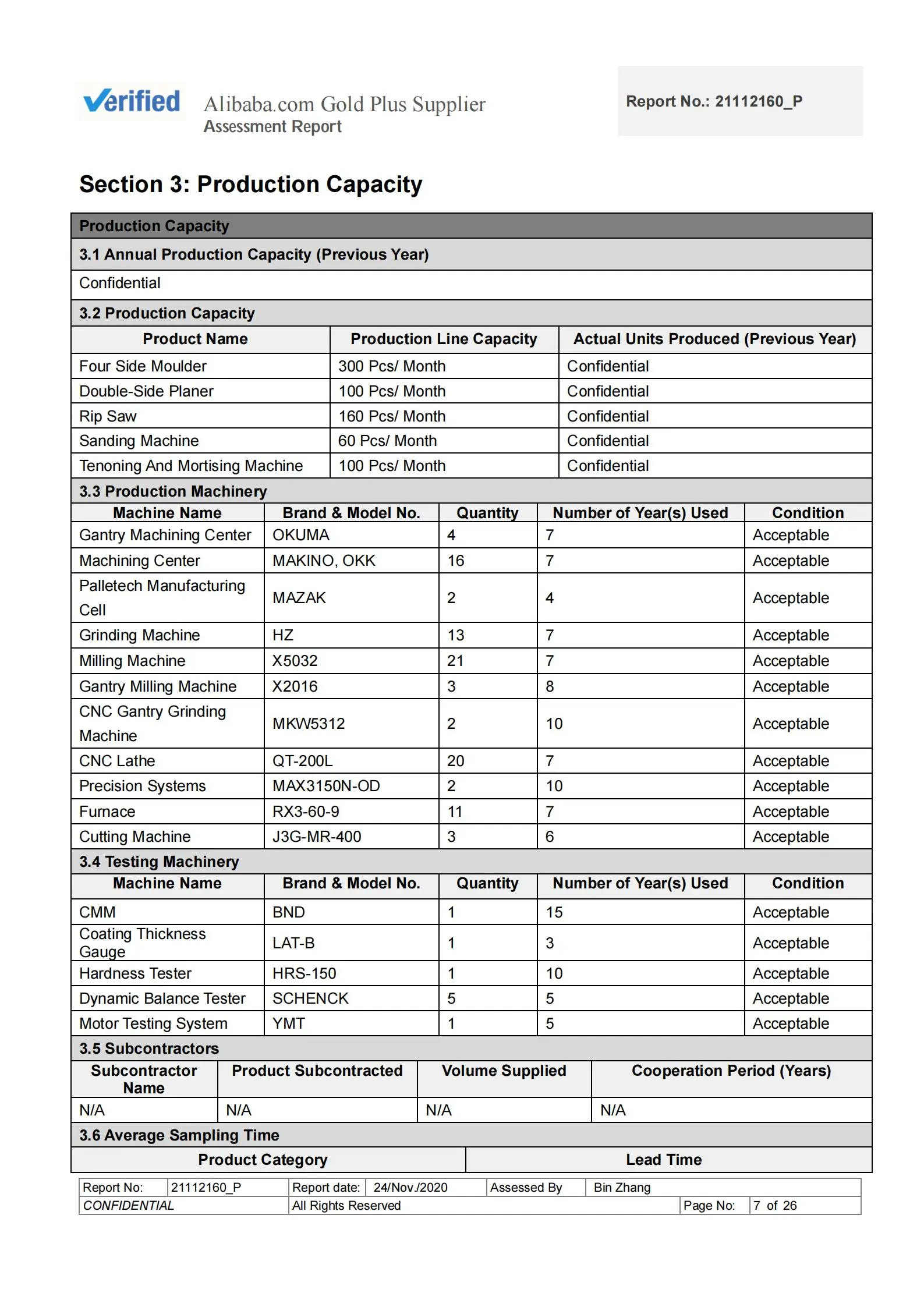

QCM Smart Panther Woodworking Machinery Tenoning and Mortising Machine MXK Series CNC Tenoner | ||||||

Technical Parameter | ||||||

Specifications | Unit | MXK3812A | MXK3821A | |||

Working length | mm | 250-1200 | 200-2100 | |||

Working width | mm | 10-115 | 10-160 | |||

Maximum processing thickness of tenon | mm | 20 | 20 | |||

Max.tenon length | mm | 40 | 40 | |||

Milling tenon speed | r/mm | 12000 | 1200 | |||

Milling spindle dia. | mm | Ф30 | Ф30 | |||

X-axis rotation Angle | ° | -5°-+15° | ±10° | |||

Y-axis rotation Angle | ° | ±15° | 45°/12° | |||

Total motor power | kW | 11.4/15 | 13.2/18 | |||

Milling spindle motor power | kW | 2*3.7/5 | 2*3.7/5 | |||

X-axis motor | kW | 2*1/1.3 | 2*1.1/1.5 | |||

Y-axis motor | kW | 2*1/1.3 | 2*0.9/1.2 | |||

Width adjusting motor | kW | 0.75 | 0.75 | |||

Vacuum port diameter | mm | 2*Ф100 | 2*Ф100 | |||

Overall dimensions | mm | 2650*1400*1700 | 4000*1600*1750 | |||

Weight | kg | 1950 | 2300 | |||

Our Advantages

Product Main Features

Product Main Features

1. The bed is made of high-quality steel through special welding and vibration aging treatment, and precision processing by the gantry machining center, with stable performance and high precision.

2. The X, Y, Z three-axis movement adopts imported linear guide, ball screw, precision helical rack and helical gear, with stable performance and high precision.

3. The X-axis drive adopts a precision planetary reducer and a high-efficiency servo motor for stable operation and high precision.

4. X, Y, Z three-axis linkage adopts the international brand Delta's high-efficiency full servo drive system, and the Z-axis (vertical) servo motor has a brake, which has stable performance and high processing accuracy.

5. The international brand Delta CNC numerical control system using traps, man-machine interface, easy to learn, ordinary workers can operate after 2-3 hours of training, and adjustment is more convenient.

6. The milling shaft adopts 18000r/min, 3kw variable frequency high-speed electric spindle, equipped with imported frequency converter, suitable for processing wooden brand tongue and groove of different materials and specifications.

7. Adopt 4-axis multi-station high-speed milling, double-station processing, alternate work, continuous production, very high production efficiency, which can effectively reduce the labor intensity of the operator.

8. CNC input and output, each group of workpieces are positioned and processed at one time to ensure the consistency of batch processing and achieve high quality and high precision of processed parts.

9. Using numerical control programming, it is suitable for processing various workpieces with different shapes and different specifications of slot holes, especially for multiple tongue grooves, long tongue grooves, small spacing tongue grooves, hole and groove combinations, tongue groove depths and complex irregular shapes Workpiece processing has significant advantages.

10. Equipped with an automatic lubricator to deliver enough lubricating oil to all linear guides, racks, and gears to maintain smooth operation.

Related Products

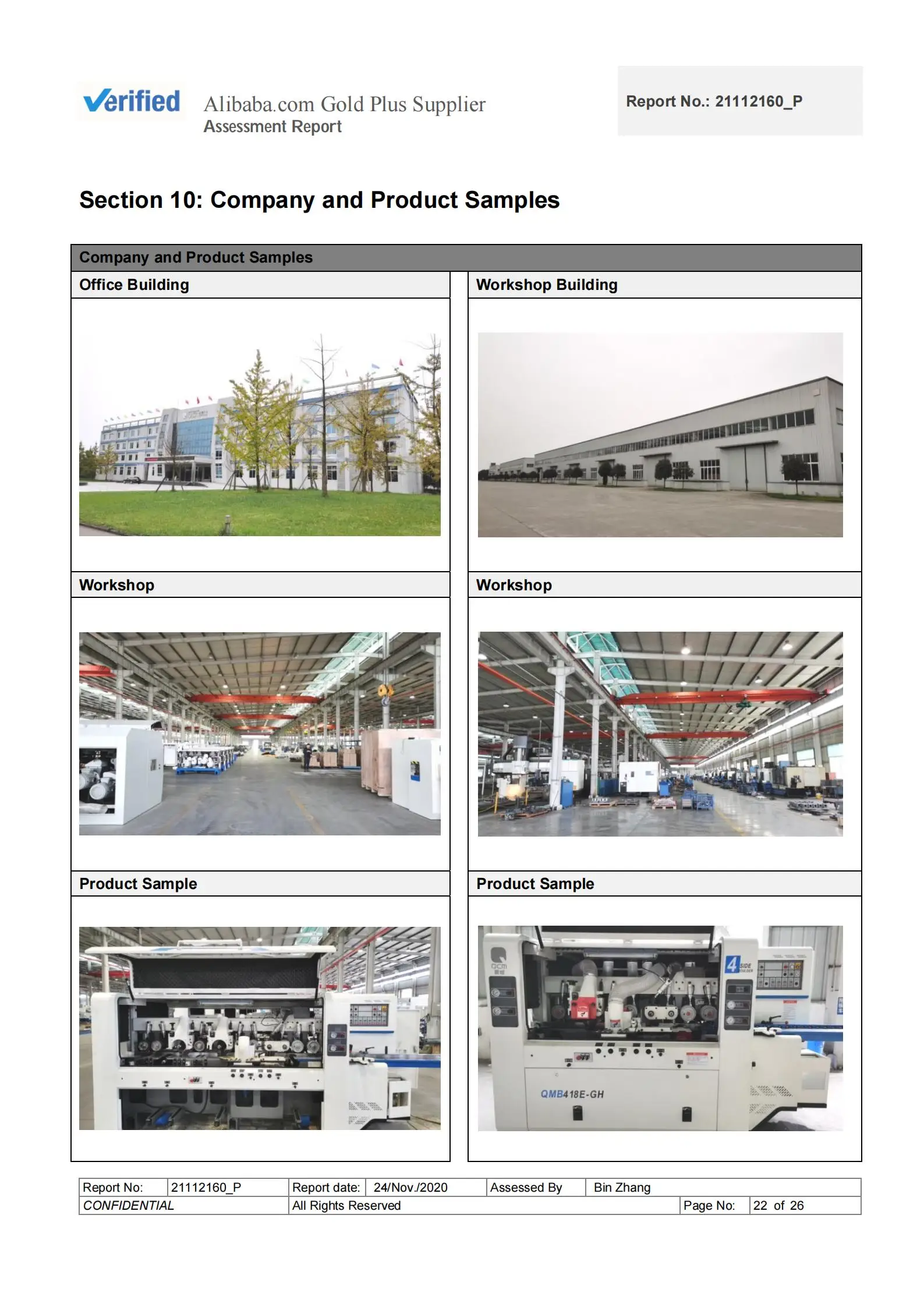

Company Information

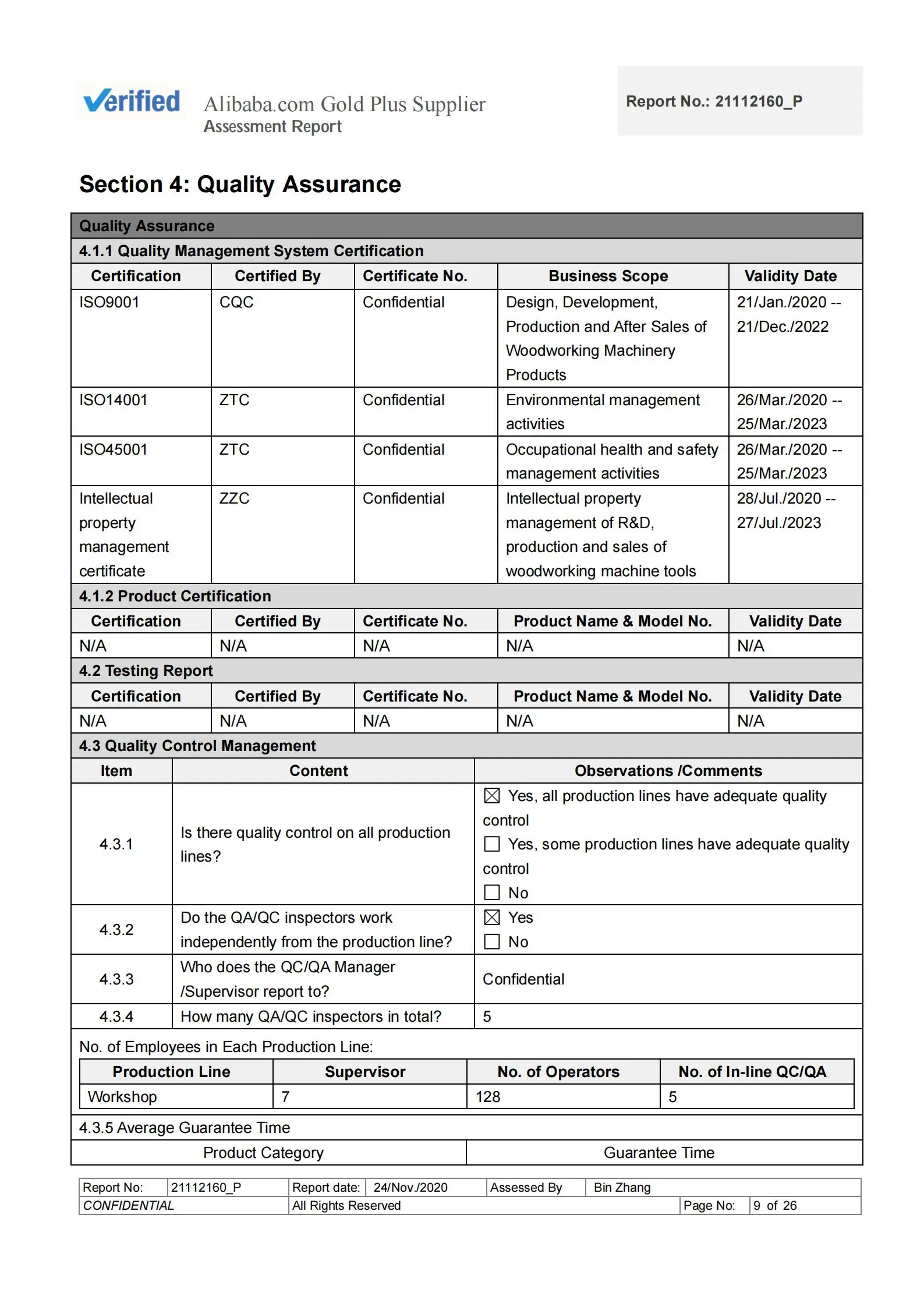

Certificate & Delivery

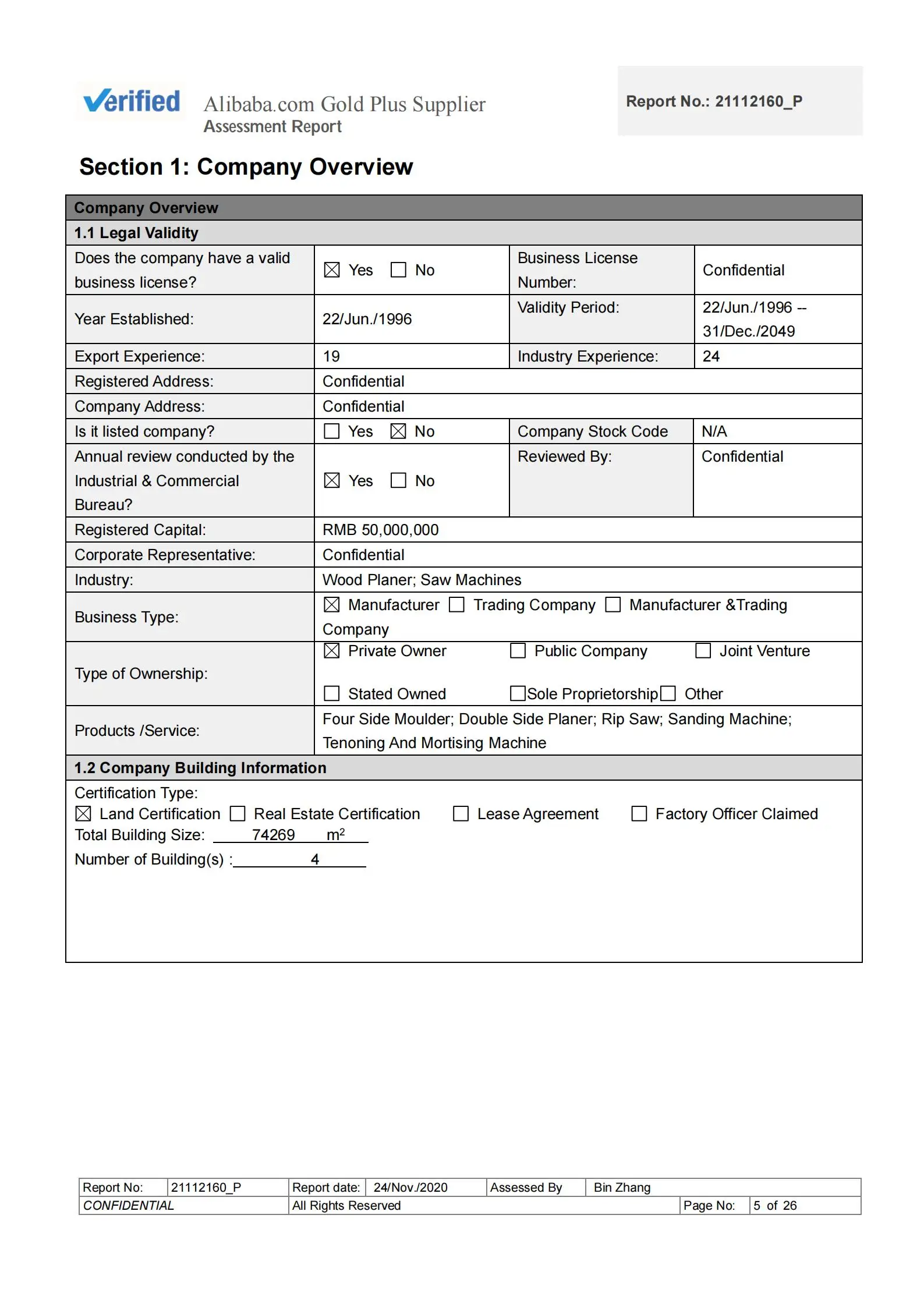

HUZHOU QINGCHENG MACHINERY CO., LTD

HUZHOU QINGCHENG MACHINERY CO., LTD

QCM Machinery was established in 1970 and have been specializing in production of woodworking machinery for more than 50 years now.

We have our own casting workshop and more than 300 sets of modern CNC machining equipment and testing equipment. Strong R&D team with 55 people can provide our customers with the biggest professional technical support.

Choose our machinery, to help you improve productivity, processing quality, and profit.

FAQ

1. Manufacturer or Trading company? QCM (Qingcheng Machinery) is a professional manufacturer of woodworking machinery since 1970. With more than 50 years experience, we have developed to be the top and most powerful manufacturer of woodworking machinery in China. 2. Payment Term? TT , 50% advance payment and 50% balance before delivery. 3. Lead Time? Within 15 days for regular stock machine after receiving advance payment. 45-60 days for customized machines. 4. Warranty ?

3 years for machine, 3 years for the core components. 5. Spare Parts? Unified standards spare parts are available anytime. It will not be a problem if you want to replace spare parts of the machine you bought anytime. 6. Pre-sale Service? As a leader in woodworking machinery field for more than 50 years, professional and efficient proposals can be provided anytime. Our strong R&D team with more than 50 persons are also your team. 7. After-sale Service? Professional after-sales service team, 24 hours technical support by email, call and video. If remote support is not workable, our engineer is available to visit at your expenses of accommodation and round tickets.

8. Why us? 1). 50 years experience in wood working machinery since 1970. 2). Our own casting workshop to insure extra heavy one-piece cast iron machine body for maximum stability and rigidity by standard configuration. 3). All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy. Spindle is processed in constant temperature workshop to insure high precision and stability, +-0.1mm high accuracy.

4). Warranty: 3 years for machine, 3 years for the core3 years for machine, 3 years for the core

components.

MXK3821A Wooking Length 2100mm CNC Double-end Tenoning Machine /double Sided Tenoner For Sale

Похожие товары

ZICAR MDK3113 деревянная машина для резки древесины

US $9000-$11000

Станок для резки древесины для твердой деревянной двери

US $180.00-$218.00