Высокая производительность рециркуляции 2 / 4 слоя анти-коррозия ASA экструдер/пластиковые волнистая кровельная плитка делая

- Категории: Tile Making Machinery >>>

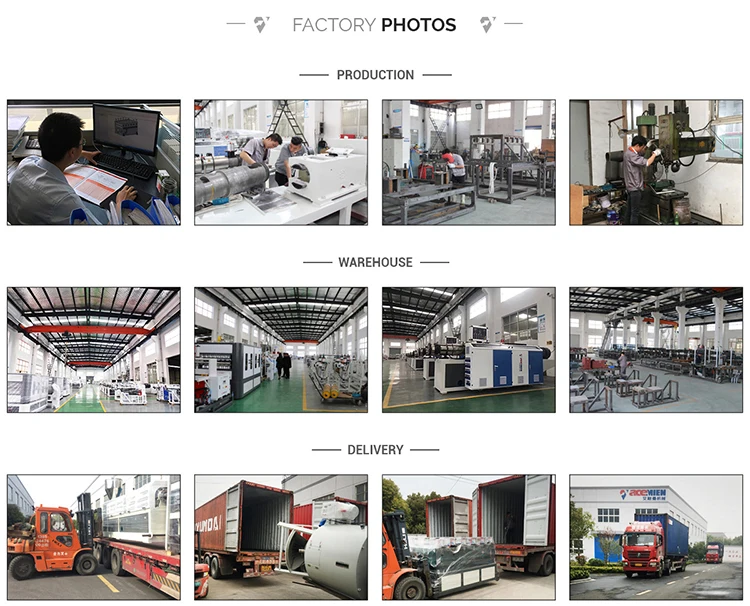

- Поставщик: Jiangsu,Acemien,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

2.Supply formula guide and staple raw material purchase

3.Professional analyzing and design by considering production cost and tiles' performance.

4.Single layer or A+B/A+B+C/A+B+A layers avaibable

Extrusion Part

1. forced extruding

2. high quality

3.wide adaptability

4.long working life

5.low shearing speed

6.hard decomposition

7.good compounding& plasticization effect

8.direct shaping of powder material and etc.

Mould Part

Name: T-DIA or Ectrusion mould

1. Clothes hanger runner

2. Mirror polishing Cr plating

3. Three dimensional flow simulation software design

Embossing Roller

1. Up roller is Embossing roller, the down roller is mirror Roller. Roller surface treatment by hard chrome plated (depth 0.10-0.15)

2. Design of spiral flow passage in roller

3. Motor separately drive to ensure consistent speed

Forming Machine

Name: Corrugated Roof Tile Forming Machine

1.Haul off roller material: Neoprene CR

2.Rise and drop method of mould: pneumatic

3.Fine adjustment method: manual

Cutter

Technical Parameters:

1.Special positioning cevice to ensure the cutting accuracy

2.Cutting method for the saw blade cutting

3.The horizontal movement motor is 0.37kw

4.PLC HMI operation

Crusher

Technical Parameters:

1.The motor power is 11kw,15kw,22kw,30kw

2.Broken the amount of 200-600kg/h

3.Broken diameter 510*290

The main purpose:

Used for on-line production to produce edge scraps for recycling

High Speed Mixer Unit

Name: High speed mixing unit

Technical parameters:

Model Capacity (kg/hr) Motor(kw)

SRL-Z200/500 350-450 30/42

SRL-Z300/600 550-650 40/55

SRL-Z500/1000 750-1000 55/75

High Speed Mixing Unite

Name: High speed mixing unit

Technical parameters:

Model Capacity (kg/hr) Motor(kw)

SRL-Z200/500 350-450 30/42

SRL-Z300/600 550-650 40/55

SRL-Z500/1000 750-1000 55/75

No. | Machine name | Qty |

1 | Screw conveyor(with push device) | 1pc |

2 | conical two screw extruder | 1pc |

3 | Vacuum feeder for pellet | 1pc |

4 | Drying hopper | 1pc |

5 | single screw extruder | 1pc |

6 | Extrusion mould | 1pc |

7 | Distributor | 1pc |

8 | Embossing roller | 1pc |

9 | Forming machine with trimming device | 1pc |

10 | Cutter | 1pc |

11 | Stacket | 1pc |

12 | Forming for ridger | 1pc |

13 | Mould of top rodge,three way ridge,hip rodge,end of ridge | 4pcs |

14 | Oven | 1pc |

15 | Mixer unit | 1pc |

16 | Screw conveyor for mixer unit | 1pc |

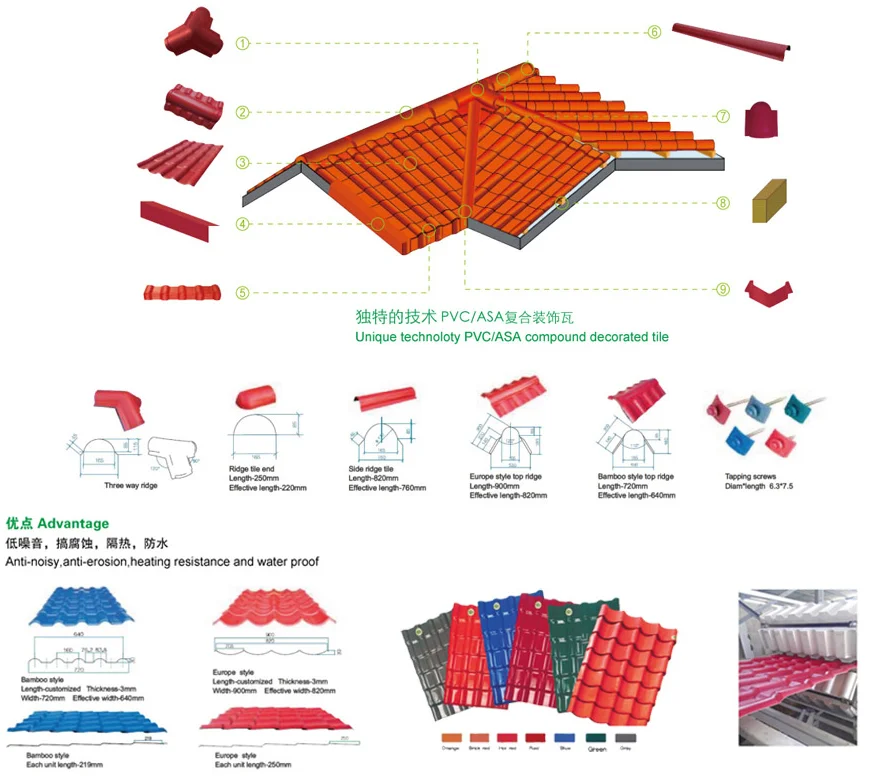

Product Application

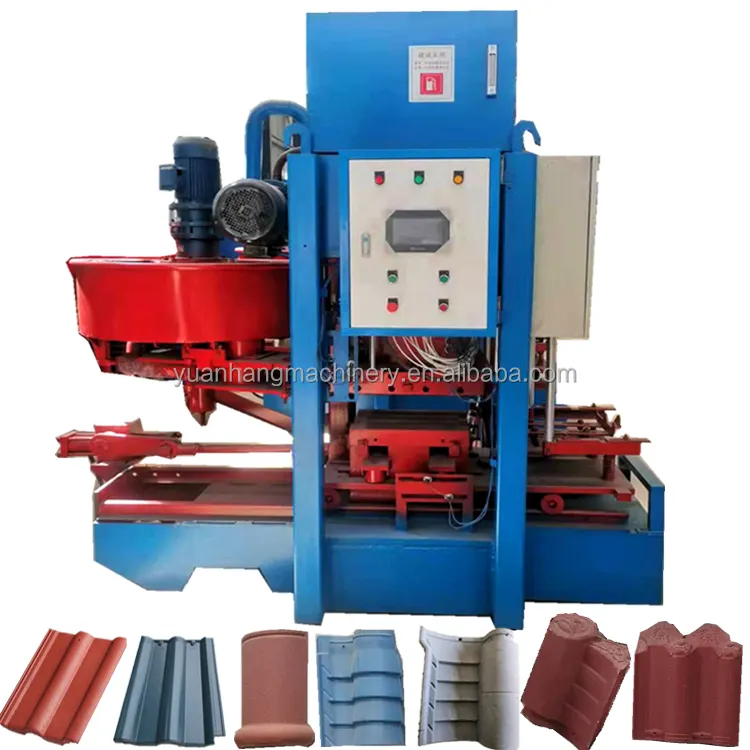

Machine name: Plastic PVC Composite Roof Tile Making machine

Finished product : Plastic roofing , PVC composite roofing , Plastic corrugated roofing

Product features:

Using life more than 20years

Good sound and heat insulation

Fire resistance, anti-corrosion

Using recycled PVC ,environment-friendly

Excellent anti-load performance

Easy to install, packing and transport