Машина для экструдирования стеновых панелей из ПВХ/машина производства/Экструзионная

- Категории: Industrial Machinery >>>

- Поставщик: Zhangjiagang,Eans,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Overview

PVC Wall Panel Extruder Machine / Making Machine / Extrusion Production Line

PRODUCT SPECIFICATIONS

PVC Wall Panel Production Line Machine List

1. Automatic raw materials feeder - 1 set

2. Double screw extruder - 1 set

3. Die and calibration mould - 1 set

4. Vacuum cooling table - 1 set

5. Hauling off - 1 set

6. Auto cutting machine - 1 set

7. Finished PVC wall panel stacker - 1 set

Features of PVC Ceiling Wall Panel Extrusion Line:

- Fetching in Europe and America advanced technology and uniting with domestic condition, our company develop this production line.

- Easy and convenient for operation and maintain

- Economical price, suitable for large scale investment.

- Easy and convenient for operation and maintain

- Economical price, suitable for large scale investment.

- This production line is used to manufacture PVC wall panel with width normally from 250mm to 300mm with different section shape and height.

- The surface of PVC ceiling / wall panel can be treated by hot stamping printing or lamination machine, which can make marble, wooden design on surface of PVC ceiling or PVC wall panel.

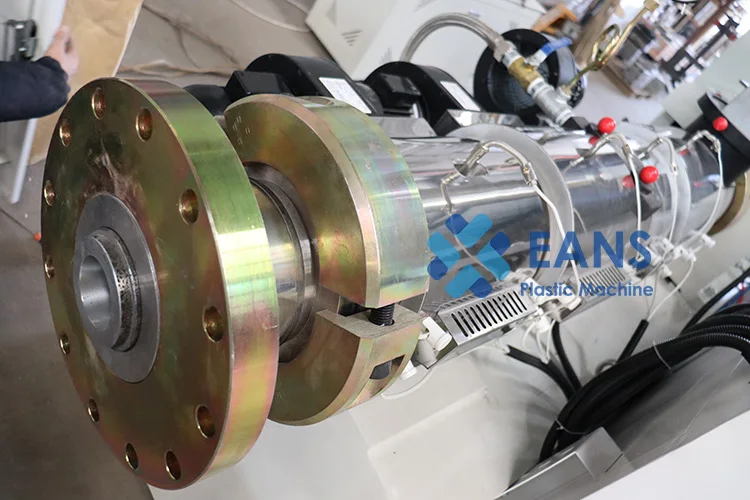

1. PVC Ceiling Wall Panel Extruder

- Machine colors: white, blue, red or customized

- Automatic screw type feeding system, raw materials do not bridge, feeding stability

- Adopts horizontal gearbox and distribution box, build in cooling oil, easy to install and maintain.

- Be equipped with ABB inverter, Siemens Motor and Schneider electrics, lower staring power, reduce voltage fluctuation and easy to adjust speed

- Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

- Flange surface be nickel-coating treatment, ensure the stable extrusion

- Flange surface be nickel-coating treatment, ensure the stable extrusion

2. Water Cooling Table

- The water collecting tank and storage tank are welded with a whole piece of stainless steel, which is not leaking for long-term use

- Be equipped with vacuum pump, recycling water, save water cost.

- The water collecting tank and storage tank are welded with a whole piece of stainless steel, which is not leaking for long-term use

- Be equipped with vacuum pump, recycling water, save water cost.

3. Hauling off

- Pull the board to increase the output of PVC wall panel.

- Use high-quality rubber blocks without hurting the PVC wall panel

- Pull the board to increase the output of PVC wall panel.

- Use high-quality rubber blocks without hurting the PVC wall panel

4. Dust free cutter with PLC controller

- According to customers needed length, cutting the PVC ceiling and wall panel

- Be equipped with PLC controller, it can set 7 sets of data, so the cutting length is adjustable freely

- According to customers needed length, cutting the PVC ceiling and wall panel

- Be equipped with PLC controller, it can set 7 sets of data, so the cutting length is adjustable freely

Model | SJ 51 | SJ 53 | SJ 55 | SJ 65 |

Diameter of screw | 51/105 | 53/128 | 55/110 | 65/132 |

Speed (KG/H) | 120 | 150 | 200 | 280 |

Weight (KG) | 3200 | 3300 | 3300 | 4000 |

PVC ceiling / wall panel cladding samples be manufactured from Eans Machinery

Successful Project

Formula

1 - We can free offer detailed formula for each products, please feel free SEND a INQUIRY for detailed information.

2 - We also can offer the design of workshop and product suggestion.

Installation / Debug / Training

1 - We can free offer detailed formula for each products, please feel free SEND a INQUIRY for detailed information.

2 - We also can offer the design of workshop and product suggestion.

Installation / Debug / Training

1 - We will arrange seasoned technician for installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

Quality Guarantee

1 - The equipment will be tested and run for few hours before leaving the factory, to ensure the smooth working

2 - One year warranty for PVC line, after warranty, we offer best price of easy broken parts.

After-sales Service

1 - We offer main parts and offer other parts at the favorable price at any stage

2 - After quality guarantee, we offer technology support, online and offline guidance.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

Quality Guarantee

1 - The equipment will be tested and run for few hours before leaving the factory, to ensure the smooth working

2 - One year warranty for PVC line, after warranty, we offer best price of easy broken parts.

After-sales Service

1 - We offer main parts and offer other parts at the favorable price at any stage

2 - After quality guarantee, we offer technology support, online and offline guidance.

Attention:

1. More detailed information, please send inquiry to us.

2. When sending inquiry or message, please tell us your Email or WhatsApp / Wechat / Skype .etc, then our sales manager can contact you quickly.

1. More detailed information, please send inquiry to us.

2. When sending inquiry or message, please tell us your Email or WhatsApp / Wechat / Skype .etc, then our sales manager can contact you quickly.

Our Company

Zhangjiagang Eans Machinery Co.,Ltd. specialized in plastic extrusion machine and other plastic auxiliary machine. Eans machinery is a professional manufacturing enterprise that integrates development, manufacturing, technical services and marketing. We provide factory construction, installation, commission, training and so on to customers.

Eans machinery has a construction area of nearly 5000 square meters and more than 50 employees. Our factory has multiple sets of advanced production equipment: CNC knife sharpener, automatic die-engraving machine, 300T/400T/630T forging press, shot blasting machine, Spray room, etc. The machines have passed SGS, CE certification, etc.

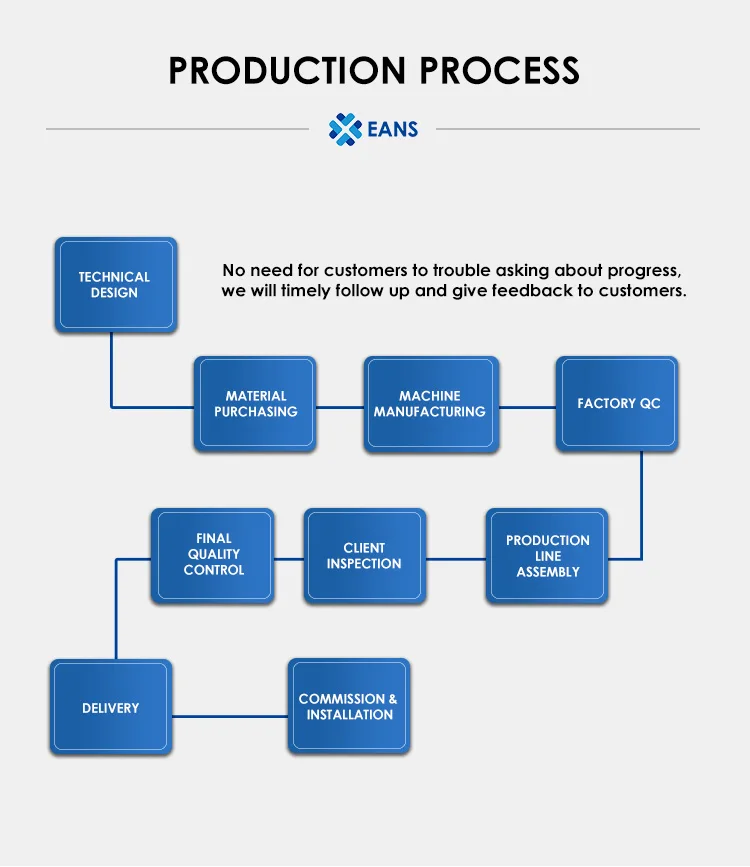

Production Progress

FAQ

Q1. Are you a factory or a trading company?

A1: EANS is a high-end export brand of EANS Group. We have our own factory, and many high-quality suppliers. We provide "all-in-one solution" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed satisfaction, you will never overpay again.

Q2. Are there other machine not listed in the catalog?

A2. EANS provides all different types of plastic extrusion solutions. If you cannot find the exact machine you are looking for, please contact us, we will be happy to develop with you and become your long-term trustworthy Chinese factory!

Q3. Can I get free samples?

A3. EANS can send free samples. But you need to pay the cost of Express which can be reduced in the order of machine in the future.

Q4. How long will I receive the quotation?

A4. Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 8 hours.

Q5. How do I get response quickly?

A5. If you send email, whatsApp, WeChat to contact us, we promise to reply to you within 8 hours! WhatsApp is the best and 24 hours online.

A1: EANS is a high-end export brand of EANS Group. We have our own factory, and many high-quality suppliers. We provide "all-in-one solution" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed satisfaction, you will never overpay again.

Q2. Are there other machine not listed in the catalog?

A2. EANS provides all different types of plastic extrusion solutions. If you cannot find the exact machine you are looking for, please contact us, we will be happy to develop with you and become your long-term trustworthy Chinese factory!

Q3. Can I get free samples?

A3. EANS can send free samples. But you need to pay the cost of Express which can be reduced in the order of machine in the future.

Q4. How long will I receive the quotation?

A4. Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 8 hours.

Q5. How do I get response quickly?

A5. If you send email, whatsApp, WeChat to contact us, we promise to reply to you within 8 hours! WhatsApp is the best and 24 hours online.