Высококачественный ламинат огнестойкая и компактная мебель на водной основе

- Категории: Decorative High-Pressure Laminates \/ HPL >>>

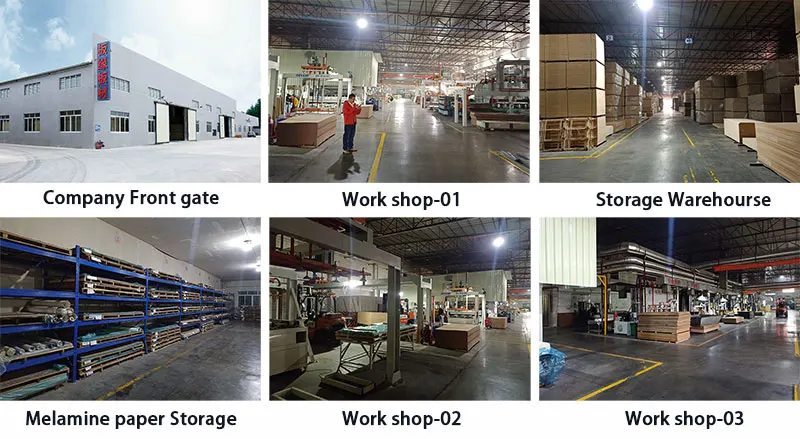

- Поставщик: FOSHAN,BANYUAN,Decorative,Materials,Co.,Ltd

Поделиться:

Описание и отзывы

Характеристики

HPL phenolic board facade wall panel exterior HPL board for wall cladding

Product Description

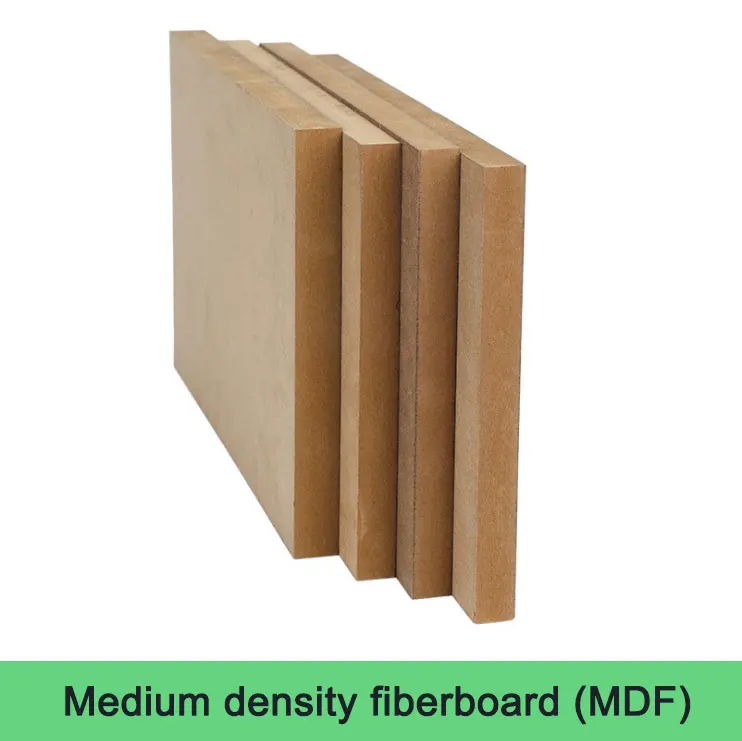

Compact laminate board /High pressure laminate -HPL

The anti-fold special board is made of decorative colored paper impregnated with melamine resin and laminated with multiple layers of black or brown kraft paper impregnated with phenolic resin. It is a high-pressure decorative board with a transparent core structure. Design and color selection, we can also provide decorative needs of "glossy surface, pearl suede, MSI surface, rhombus pattern, checkered pattern, flying snow meteor".

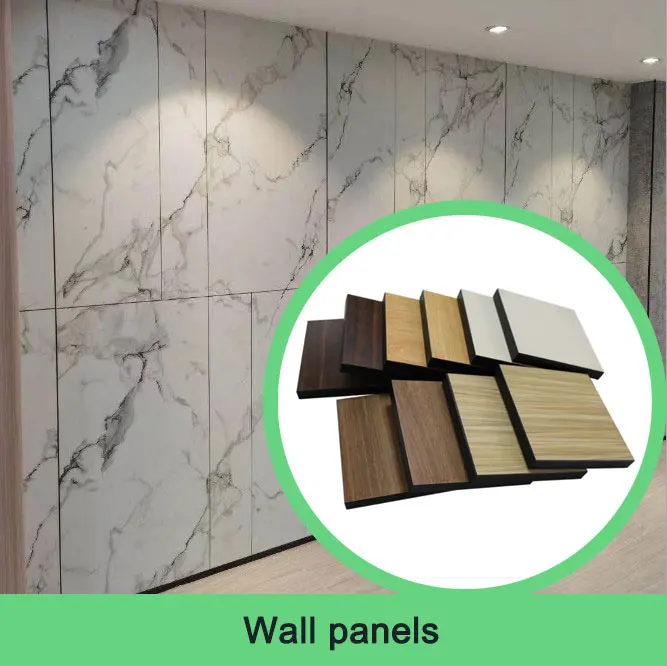

Interiors Decoration : | wall decor /floor decor /wardrobe decor tables /office furniture /kitchen |

Product name | HPL board /High pressure laminate Board |

Application | Office Building /interiors |

Place of Origin | Foshan city in China |

Model Number | BYC01 |

Surface Finishing | Finished |

Grade | Excellent |

Dimensions | 1220x2440mm / 1220x3050mm / 1830x2440 mm |

Thickness | 6mm-18mm |

Density | 1200 KG/M³ |

Glue | E0/E1/E2/Carb P2/WBP |

Color | Free Choose in our stock veneer pattern |

Keywords | Melamine Particleboard |

Certificate | CABR CE FSC ISO9001 ISO14001 |

MOQ | 1X40HQ FCL |

Advantage | Eco Friendly Board |

Laminate thermoforming process :

Hot pressing is a process of heating and pressing the slab after paving to form a fiber board with certain mechanical strength and water resistance. Whether it is wet production of rigid or semi-rigid boards, or dry production of rigid or medium density boards, hot pressing is required to become a board.

Free to choose wood veneer pattern :

Decorative layer pattern | wooden grain / marble stone /cloth grain /customize parttern |

Application Scene

Foshan Banyuan decoration materials Co.,Ltd.high-end decorative panel,high-end furniture plate supplier, The company established in 2006 years,After years efforts to have first-class production equipment and first-class professional and technical personnel for the production of high-grade plate escort.pay attention to environmental protection,formaldegyde free eop2 E1 grade MDF,particleboard,moisture-proof board,multi-layer plywood,imported pine thick core board,second-generation anti bent,suitable for office furniture,customized furniture,wall decoration. Large size plate adhere to the customer and quality of the service tenet,with the majority of new and old customers to create brilliant

Stage-1

The first stage is the preheating and preloading stage. The main purpose of this stage is to melt the resin, remove volatiles, impregnate the fibers, and gradually solidify the resin to a gel state. The molding pressure at this stage is 1/3-1/2 of the full pressure.

Stage-2

The intermediate heat preservation stage. The role of this stage is to cure the tape at a lower reaction rate. During the heat preservation process, close attention should be paid to the flow of the resin. When the flowing resin has gelled and cannot be drawn into filaments, full pressure should be applied immediately.

Stage-3

The heating stage. The purpose is to increase the reaction temperature and accelerate the curing speed. At this time, the heating rate should not be too fast, otherwise it will cause violent aggregation, so that the exothermic heat of the curing reaction is too concentrated, resulting in delamination between the material layers.

Stage-4

Hot pressing and heat preservation stage. The purpose is to allow the resin to be sufficiently cured. From the application of full pressure to the end of the entire hot pressing, it is called the hot pressing stage. The time from reaching the specified hot pressing temperature to the end of hot pressing is called constant temperature time. The temperature, pressure and constant temperature time of the hot pressing stage are also determined by the formula.

Stage-5

Cooling stage. In the case of maintaining pressure, take natural cooling or forced cooling to room temperature, then release the pressure and take out the product. If the cooling time is too short, it is easy to cause warping and cracking of the product. If the cooling time is too long, it will not help the product quality obviously, but it will obviously reduce the production efficiency.

International Certifications | ISO:9001 ISO:14001 SGS/FSC/CE |

Salesman : Ian Liao

E-Mail : Ian@fsbanyuan.com