Пневматический двухкомпонентный герметик экструдер полисульфида из

- Категории: >>>

- Поставщик: Zhengzhou,Pasen,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

1. insulating glass production line equipment Automatic butyl coating machine

Feature:

1. Pneumatic system pump are famous brand imported

2. Touching screen interface, easy operation

3. Frequency inverter conveyor system, speed adjustable from 15-30m/min.

4. Auto butyl nozzle distance adjustable from 6mm to 24mm.

5. Sealant cylinder adopts rotate structure, easy for butyl sealant load and maintenance.

6. Pre-heating system, increase the production efficiency by pre-heating time setting.

7. Advanced device guarantees the best spreading effect on the arc aluminum frame.

8. Auto butyl alarm system, alarm when there is no butyl inside the butyl tank.

9. Butyl sealant cylinder volume is 14KG

2. Touching screen interface, easy operation

3. Frequency inverter conveyor system, speed adjustable from 15-30m/min.

4. Auto butyl nozzle distance adjustable from 6mm to 24mm.

5. Sealant cylinder adopts rotate structure, easy for butyl sealant load and maintenance.

6. Pre-heating system, increase the production efficiency by pre-heating time setting.

7. Advanced device guarantees the best spreading effect on the arc aluminum frame.

8. Auto butyl alarm system, alarm when there is no butyl inside the butyl tank.

9. Butyl sealant cylinder volume is 14KG

machine name | Automatic butyl coating machine |

voltage | 380v 50 HZ 3 phase |

power | 3.2 KW |

machine size | 3000*700*1300 mm |

machine weight | 600 kgs |

glass thickness | 3-18 mm |

butyl extruding speed | 4-40 M/min |

air pressure | 0.6-0.8 Mpa |

heating temperature | 100-180 degree |

hydraulic pressure | 8-12 Mpa |

butyl heating time | 40 mins |

remarks | we also have other kind of machine model. whatsapp:0086-15937125109 |

2.. Insulating Glass Two Component Sealant spreading machine

1. There are high-pressure valves in the underpart entrance of solidification Pharmaceutitcal filter and material-feeding place of the mixing device and one-way valve is set in the mixing device so as to prevent two-components from fleeing each other.

2. Rising and falling system is controlled by hand valve and the proportion of the two-components can be changed by adjusting the slipper in the swinging pole. Tighening the nut once the demanding scale is reached.

machine name | Insulating Glass Two Component Sealant spreading machine |

Mixing ration proportion of misture | 6:1---14:1 |

Raw material barrel | 55 gallon (200 l) |

Solidification pharmaceutical barrel | 5 gallon (20 L)285 mm |

Max air-consumption volume | 1m3/min |

Max squeeze pressure | 25 Mpa |

Air source pressure | 0.5-0.8 Mpa |

Machine size | 1450*850*1860 mm |

Machine weight | 550 kgs |

remarks | we also have other kind of machine model. whatsapp:0086-15937125109 |

Product Paramenters

Why Choose Us

1, More than 20 years' manufacturing experience and 10 years' exporting experience.

2, Alibaba Assessed Gold Supplier.

3, 100% QC inspection Before Shipmeng.

4, Best Quality & Best Service with Competitive price.

Our company provides technical support and fittings for life. After-sales service isn't restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

5, About machine packing if LCL, they will be wrapped in plastic film first before packing, which is to avoid moisture on the sea then they will be putted in strong iron sheet case/wooden case which is free of fumigation, lined with metal wire if necessary.

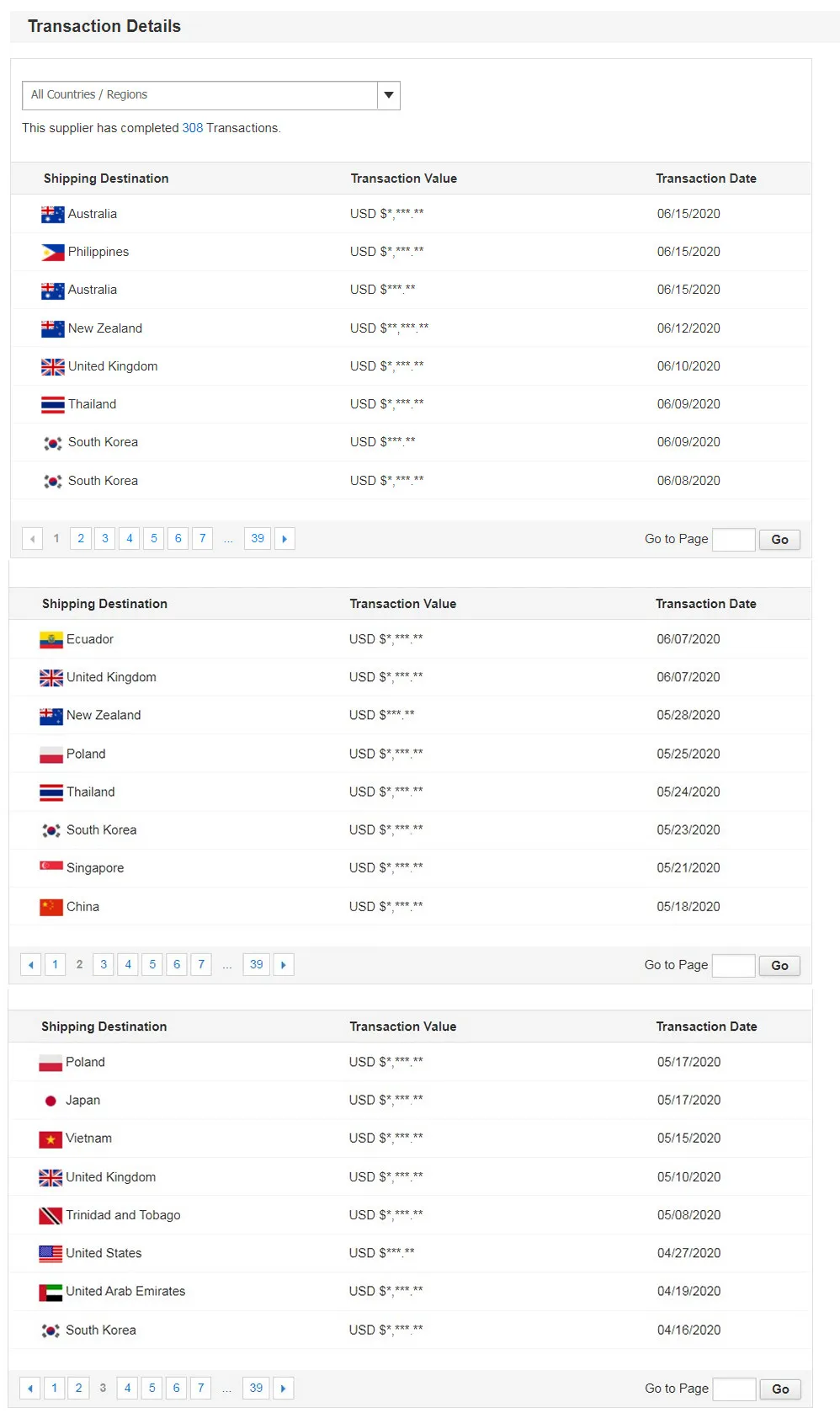

Transaction History

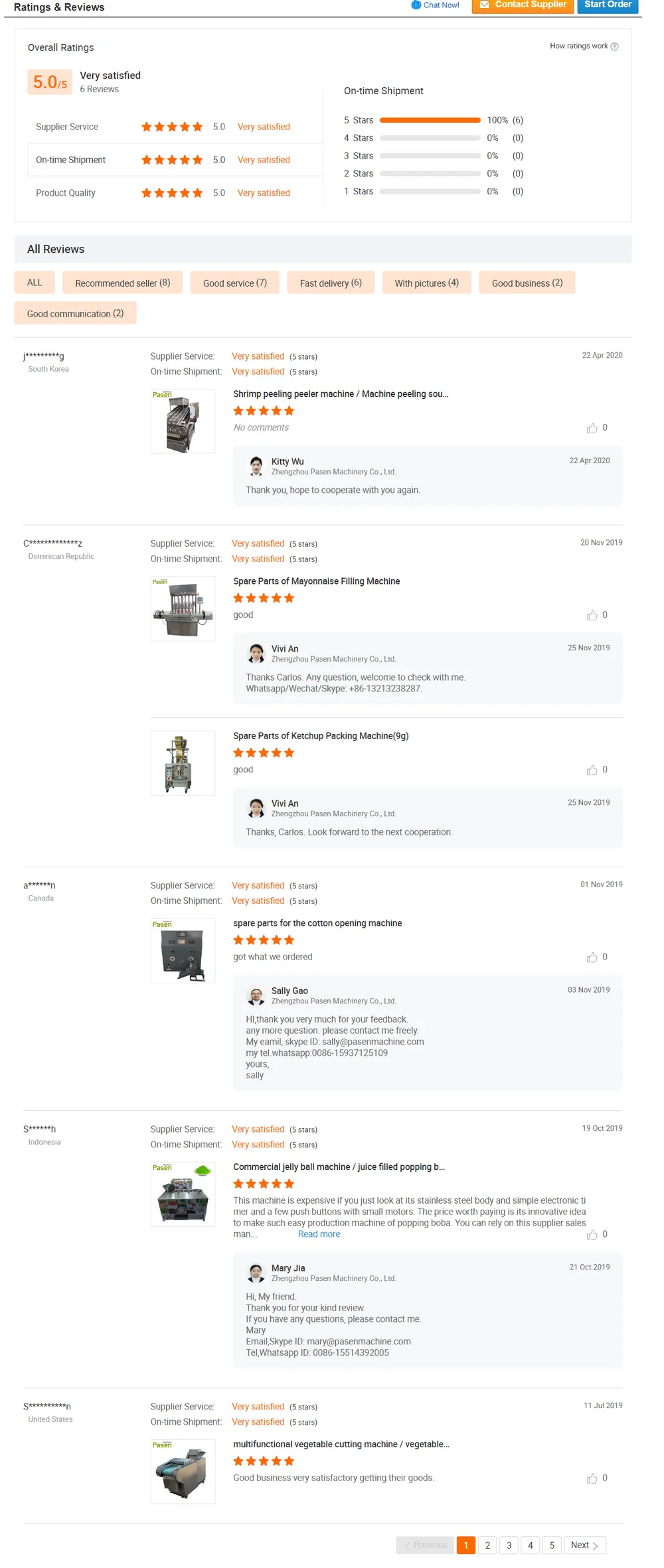

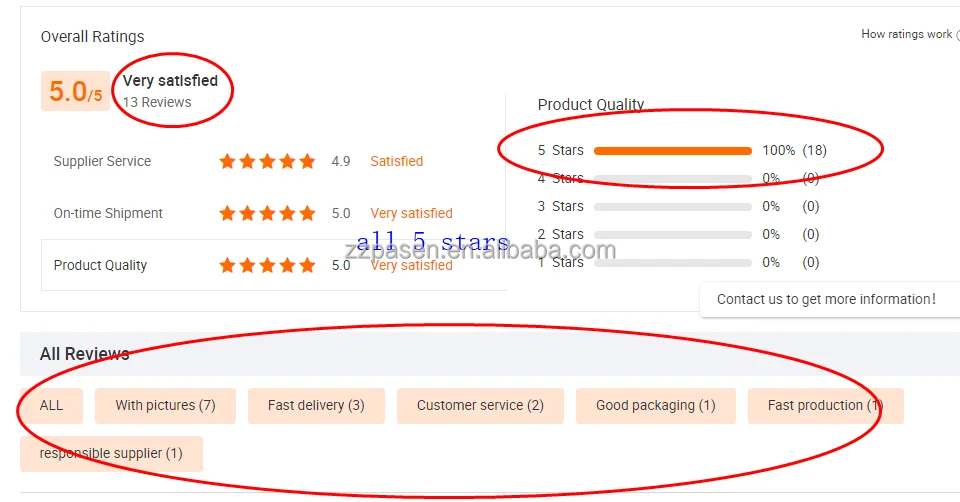

Customers' Rating

Company Profile

customer feedback : all 5 stars reviews+ very satisfied.

FAQ

1, Are you manufacturer?

Yes, we are manufacturer with more than 15 years' experience.

2,Can you ship the machine to my address?

Yes, we could use DHL to express the machine. While transport cost will be higher than by sea.

3, Where are you? Can we go to China and visit your factory?

Yes, of course. We are in Henan, China. Welcome to our factory.

4, Do you have manual with the machine?

Yes, of course. It is in English version.

5, Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you the commercial invoice, sales contract, packing list, bill of lading(FOB or CFR, CIF terms), insurance policy (if CIF terms), also CO if you need.

Yes, we are manufacturer with more than 15 years' experience.

2,Can you ship the machine to my address?

Yes, we could use DHL to express the machine. While transport cost will be higher than by sea.

3, Where are you? Can we go to China and visit your factory?

Yes, of course. We are in Henan, China. Welcome to our factory.

4, Do you have manual with the machine?

Yes, of course. It is in English version.

5, Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you the commercial invoice, sales contract, packing list, bill of lading(FOB or CFR, CIF terms), insurance policy (if CIF terms), also CO if you need.

Contacts

Похожие товары

Стеллаж для транспортировки поддонов L-образной стеклянной полки

US $160.00-$180.00

Легко отлаживать станок для полировки стекла с ЧПУ

US $7200-$7400