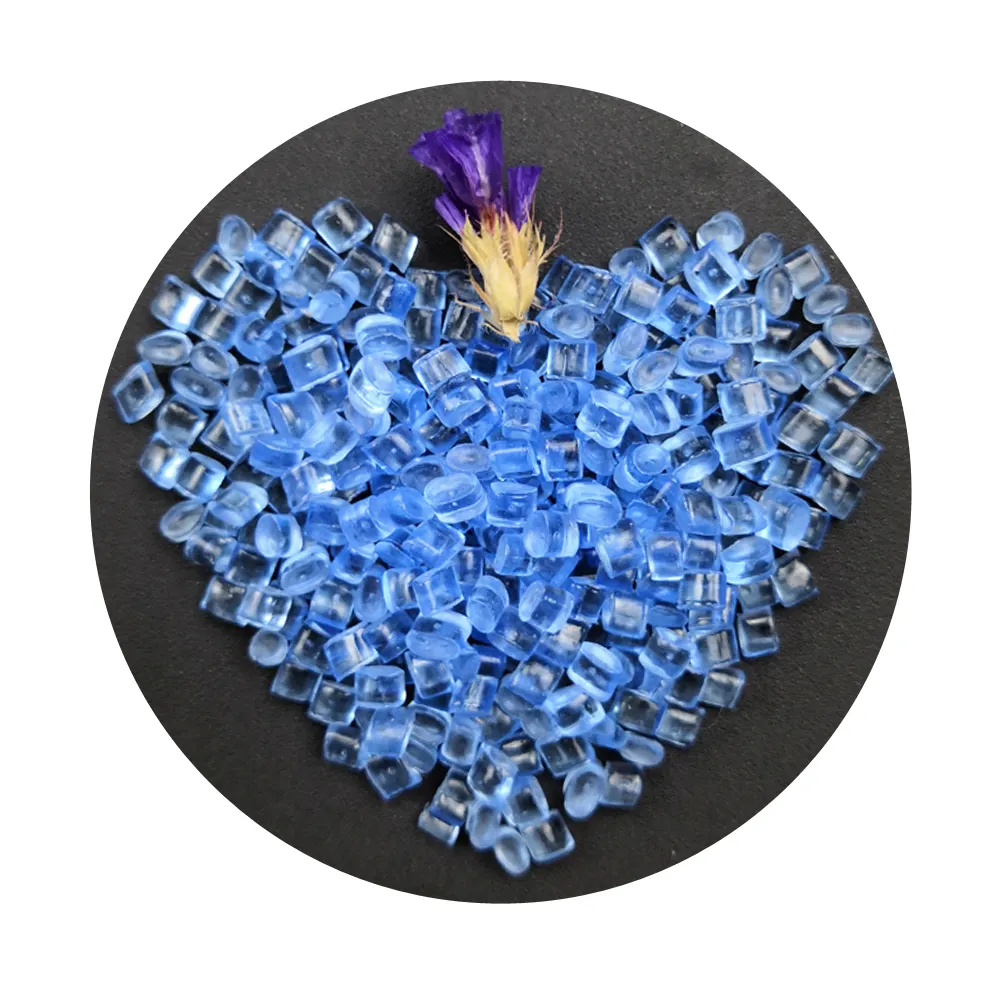

Белый цвет PA66 PA6 GF35 GF30 Полиамид пластик PA нейлон

- Категории: Plastic Raw Materials >>>

- Поставщик: Hebei,Lonni,Imp&Exp.,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

PA

Polyamide(PA) are also commonly known as Nylon, the most common types of polyamides are PA6 and PA66, which are characterized by balanced mechanical, electrical and tribological properties. Nylons are often material of choice when it comes to applications that require high strength, rigidity and flame retardant ability.

Product Description | Applications | |||||||||||||||||

·30%66 30% glass fiber reinforced PA66 | · Injection molding | |||||||||||||||||

· Excellent heat stability | · Good mechanical properties balance | |||||||||||||||||

Properties | Test Method | Test Condition | Unit | Typical Values | ||||||||||||||

Physical properties | ||||||||||||||||||

Specific Gravity | ISO 1183 | 23ºC | g/cm3 | 1.35 | ||||||||||||||

Ash | ISO 3451 | 800ºC,30min | % | 30 | ||||||||||||||

Mechanical properties | ||||||||||||||||||

Tensile Strength | ISO 527 | 50mm/min | MPa | 150 | ||||||||||||||

Elongation at Break | ISO 527 | 50mm/min | % | 2 | ||||||||||||||

Flexural Modulus | ISO 178 | 2mm/min | MPa | 7500 | ||||||||||||||

Charpy Notched Impact Strength | ISO 179-1eA | 23ºC | kJ/m2 | 9 | ||||||||||||||

Charpy Unotched Impact Strength | ISO 179-1eU | 23ºC | kJ/m2 | 70 | ||||||||||||||

Thermal properties | ||||||||||||||||||

Heat deflection temperature | ISO 75 | 1.80MPa | C | 245 | ||||||||||||||

Melting Point | DSC | - | C | 262 | ||||||||||||||

Other properties | ||||||||||||||||||

Mold Shrinkage | internal test method | 48 hours after tool | % | 0.3-0.6 | ||||||||||||||

Flammability | TL1010 | - | mm/min | 35 | ||||||||||||||

Specification

item | value |

Place of Origin | China |

Hebei | |

Brand Name | OEM |

Model Number | PA |

Product name | PA66 granules |

Full name | Polyamide |

Color | White |

Grade | Virgin Grade |

Application | automobile engine, radiator tank parts |

MOQ | 1kg |

Sample | support |

Package | 25kgs/bag |

Delivery time | 1-2 Weeks |

Packing & Delivery

1.Packing:

In 25kg PP woven bag, or per your requirement.

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the

open air.

3.Transportation:

During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

In 25kg PP woven bag, or per your requirement.

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the

open air.

3.Transportation:

During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

Applications

It's used for Inlet manifold of automobile engine, radiator tank parts, motor cover, tire cover, tension wheel, cooling fan,

jetting machine accessories, electronics, connection terminal, disconnector, bearing cage, power tools cover, high performance gear, coil skeleton, textile accessories and so on.

jetting machine accessories, electronics, connection terminal, disconnector, bearing cage, power tools cover, high performance gear, coil skeleton, textile accessories and so on.

Company Profile

For more than 20 years, our company has purchased and supplied a large number of high-quality products for industrial and agricultural customers all over the world, such as flame retardants and fertilizers. We sincerely welcome more clients to cooperate with us.

FAQ

1. who are we?

We are based in Heibei, China, start from 2018,sell to Mid East(25.00%),South Asia(15.00%),Domestic Market(10.00%),Northern Europe(10.00%),South America(10.00%),North America(10.00%),Eastern Europe(10.00%),Southern Europe(5.00%),Western Europe(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3: Can I get some samples?

4: Do you receive customized order?

5.What's the lead time?

We are based in Heibei, China, start from 2018,sell to Mid East(25.00%),South Asia(15.00%),Domestic Market(10.00%),Northern Europe(10.00%),South America(10.00%),North America(10.00%),Eastern Europe(10.00%),Southern Europe(5.00%),Western Europe(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3: Can I get some samples?

Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

4: Do you receive customized order?

Yes, ODM & OEM are welcomed.

5.What's the lead time?

According to the order quantity, less than 10 tons need 5-7 days, More than 10 tons need negotiation.

6: What's your payment terms?

We accept T/T, L/C at sight

Our Advantages

1.Prompt reply & instant communication available.

2.Samples provided for free.

3.Customized packaging bag.

4.Large stocking & lightning consignment.

5.Photos all-the-way for cargo tracing after order confirmation

6.Quality guaranteed that every item comes from the first class factory.

7.One-stop tracking service until the goods trucked to your warehouse.

2.Samples provided for free.

3.Customized packaging bag.

4.Large stocking & lightning consignment.

5.Photos all-the-way for cargo tracing after order confirmation

6.Quality guaranteed that every item comes from the first class factory.

7.One-stop tracking service until the goods trucked to your warehouse.

Recommend Products

More need, please don't hesitant to contact us.

Welcome to your inquiry.

Похожие товары

Шарики из пенопласта, шарики из пенопласта для рукоделия

US $0.25-$0.32

Шарики из пенопласта, шарики из пенопласта для рукоделия

US $0.25-$0.32