Низкий уровень шума подшипник двигателя цилиндрический роликовый NJ208

- Категории: Cylindrical Roller Bearings >>>

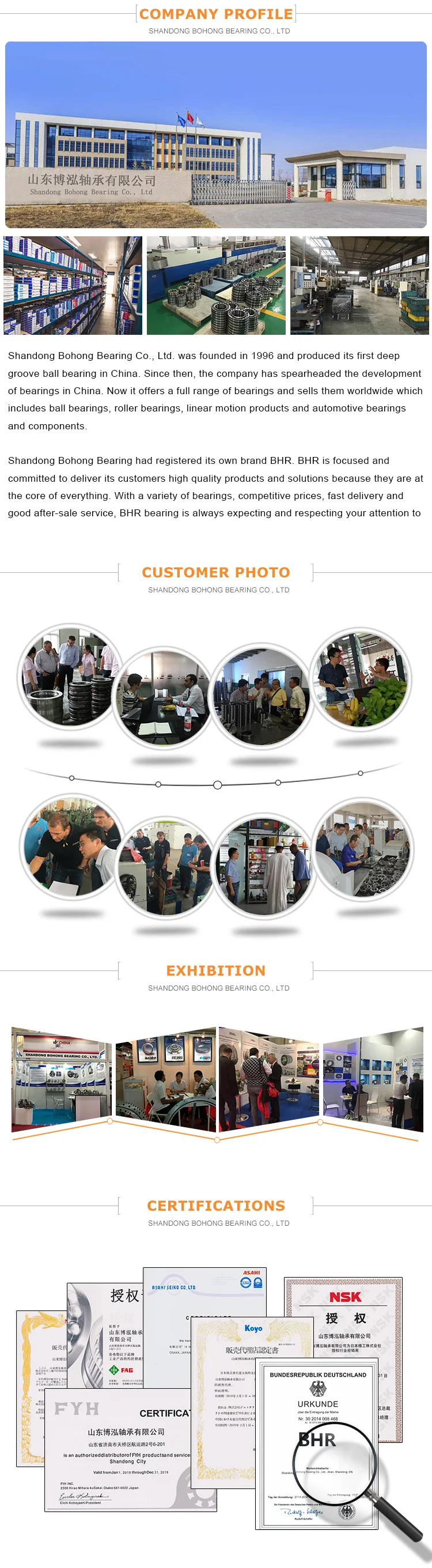

- Поставщик: Shandong,Bohong,Bearing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

low noise motor bearing cylindrical roller bearing NJ208 NJ208ECP NU208

1. Cylindrical roller and raceway are in line contact or trimmed line contact, with large radial bearing capacity, suitable for bearing heavy load and impact load.

2. N type and NU type can move axially, which can adapt to the change of the relative position of the shaft and the shell caused by thermal expansion or installation error, and can be used as free end support.

3. The processing requirements for parts such as shafts or seat holes are relatively high. After the bearing is installed, the axis of the outer ring is relatively skewed, which should be strictly controlled to avoid contact stress concentration.

4. The friction coefficient is small, suitable for high-speed rotation, and the limit speed is close to that of deep groove ball bearings.

5. Cylindrical roller bearings are separable bearings, the inner ring or outer ring can be separated for easy installation and disassembly.

Specifications: cylindrical roller bearing | |

Number of row | single row |

Bearing types | cylindrical roller bearing |

Precision rate | grade p0 p4 p5 p6 abec5 |

| Brass Material | Nylon, Steel, Brass |

Dimensions: | |

Bore Size d | 40 mm |

Outside Diameter D | 80 mm |

Outside Ring Width B | 18 mm |

Bearing features: | |

origin | china shandong bearing |

advantage | hot sale high speed long life roller bearings |

China bearing cylindrical roller bearing single row

| Principal dimensions | Basic load ratings | Fatigue load limit | Speed ratings | bearing | ||||

| dynamic | static | Reference | Limiting | number | ||||

| d | D | B | C | C0 | Pu | speed | speed | |

| mm | kN | kN | r/min | |||||

| 75 | 130 | 31 | 186 | 208 | 27 | 5600 | 6000 | NJ 2215 ECPH |

| 75 | 160 | 37 | 280 | 265 | 33.5 | 4500 | 5300 | NJ 315 ECP |

| 75 | 130 | 31 | 186 | 208 | 27 | 5600 | 6000 | NU 2215 ECPH |

| 75 | 160 | 37 | 280 | 265 | 33.5 | 4500 | 5300 | NJ 315 ECJ |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NU 316 ECP |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NU 316 ECJ |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NJ 316 ECPH |

| 80 | 200 | 48 | 303 | 320 | 39 | 3800 | 4500 | NJ 416 |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NUP 316 ECP |

| 80 | 170 | 58 | 415 | 440 | 55 | 4300 | 5000 | NUP 2316 ECP |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NU 2216 ECJ |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NU 2216 ECP |

| 80 | 170 | 58 | 415 | 440 | 55 | 4300 | 5000 | NJ 2316 ECP |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | NUP 216 ECP |

| 80 | 200 | 48 | 303 | 320 | 39 | 3800 | 4500 | NU 416 |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | N 316 ECP |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NJ 2216 ECP |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NJ 2216 ECJ |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NUP 2216 ECP |

| 80 | 140 | 33 | 212 | 245 | 31 | 5300 | 5600 | NUP 2216 ECJ |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NJ 316 ECP |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NJ 316 ECJ |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | N 216 ECP |

| 80 | 170 | 58 | 415 | 440 | 55 | 4300 | 5000 | NU 2316 ECP |

| 80 | 170 | 39 | 300 | 290 | 36 | 4300 | 5000 | NU 316 ECPH |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | NJ 216 ECJ |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | NJ 216 ECP |

| 80 | 125 | 22 | 64.4 | 78 | 9.8 | 6300 | 6300 | NU 1016 |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | NU 216 ECP |

| 80 | 140 | 26 | 160 | 166 | 21.2 | 5300 | 5600 | NU 216 ECJ |

| 85 | 180 | 60 | 455 | 490 | 60 | 4000 | 4800 | NJ 2317 ECP |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | N 317 ECP |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NU 2217 ECPH |

| 85 | 210 | 52 | 319 | 335 | 39 | 3600 | 4300 | NJ 417 |

| 85 | 210 | 52 | 319 | 335 | 39 | 3600 | 4300 | NU 417 |

| 85 | 150 | 36 | 190 | 200 | 25 | 4800 | 5300 | NUB 217 ECJ |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NU 317 ECP |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NU 317 ECJ |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NUP 2217 ECP |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NUP 217 ECJ |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NUP 217 ECP |

| 85 | 180 | 60 | 455 | 490 | 60 | 4000 | 4800 | NU 2317 ECJ |

| 85 | 180 | 60 | 455 | 490 | 60 | 4000 | 4800 | NU 2317 ECP |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NU 2217 ECP |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NU 2217 ECJ |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NJ 317 ECP |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NJ 317 ECJ |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | N 217 ECP |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NUP 317 ECP |

| 85 | 180 | 41 | 340 | 335 | 41.5 | 4000 | 4800 | NUP 317 ECJ |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NU 217 ECJ |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NU 217 ECP |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NJ 217 ECJ |

| 85 | 150 | 28 | 190 | 200 | 25 | 4800 | 5300 | NJ 217 ECP |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NJ 2217 ECJ |

| 85 | 150 | 36 | 250 | 280 | 34.5 | 4800 | 5300 | NJ 2217 ECP |

| 85 | 180 | 60 | 455 | 490 | 60 | 4000 | 4800 | NUP 2317 ECP |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | NU 218 ECJ |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | NU 218 ECP |

| 90 | 190 | 64 | 500 | 540 | 65.5 | 3800 | 4500 | NU 2318 ECP |

| 90 | 190 | 64 | 500 | 540 | 65.5 | 3800 | 4500 | NU 2318 ECJ |

| 90 | 190 | 64 | 500 | 540 | 65.5 | 3800 | 4500 | NUP 2318 ECP |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | NJ 318 ECJ |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | NJ 318 ECP |

| 90 | 160 | 40 | 280 | 315 | 39 | 4500 | 5000 | NUP 2218 ECP |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | NUP 218 ECP |

| 90 | 225 | 54 | 380 | 415 | 48 | 3400 | 4000 | NU 418 |

| 90 | 190 | 64 | 500 | 540 | 65.5 | 3800 | 4500 | NJ 2318 ECJ |

| 90 | 190 | 64 | 500 | 540 | 65.5 | 3800 | 4500 | NJ 2318 ECP |

| 90 | 160 | 40 | 280 | 315 | 39 | 4500 | 5000 | NU 2218 ECP |

| 90 | 160 | 40 | 280 | 315 | 39 | 4500 | 5000 | NU 2218 ECJ |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | N 218 ECP |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | NJ 218 ECP |

| 90 | 160 | 30 | 208 | 220 | 27 | 4500 | 5000 | NJ 218 ECJ |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | NU 318 ECP |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | NUP 318 ECJ |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | NU 318 ECJ |

| 90 | 160 | 40 | 280 | 315 | 39 | 4500 | 5000 | NJ 2218 ECJ |

| 90 | 160 | 40 | 280 | 315 | 39 | 4500 | 5000 | NJ 2218 ECP |

| 90 | 190 | 43 | 365 | 360 | 43 | 3800 | 4500 | N 318 ECP |

| 95 | 170 | 43 | 325 | 375 | 45.5 | 4300 | 4800 | NU 2219 ECJ |

| 95 | 170 | 43 | 325 | 375 | 45.5 | 4300 | 4800 | NU 2219 ECP |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NUP 2319 ECP |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NUP 2319 ECJ |

| 95 | 200 | 45 | 390 | 390 | 46.5 | 3600 | 4300 | NJ 319 ECP |

| 95 | 170 | 43 | 325 | 375 | 45.5 | 4300 | 4800 | NJ 2219 ECJ |

| 95 | 170 | 43 | 325 | 375 | 45.5 | 4300 | 4800 | NJ 2219 ECP |

| 95 | 200 | 45 | 390 | 390 | 46.5 | 3600 | 4300 | NJ 319 ECJ |

| 95 | 170 | 43 | 325 | 375 | 45.5 | 4300 | 4800 | NUP 2219 ECP |

| 95 | 170 | 32 | 255 | 265 | 32.5 | 4300 | 4800 | NJ 219 ECP |

| 95 | 170 | 32 | 255 | 265 | 32.5 | 4300 | 4800 | NJ 219 ECJ |

| 95 | 200 | 45 | 390 | 390 | 46.5 | 3600 | 4300 | N 319 ECP |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NU 2319 ECP |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NU 2319 ECJ |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NJ 2319 ECP |

| 95 | 200 | 67 | 530 | 585 | 69.5 | 3600 | 4300 | NJ 2319 ECJ |

| 95 | 170 | 32 | 255 | 265 | 32.5 | 4300 | 4800 | NU 219 ECP |

There are two common ways of correct installation of cylindrical roller bearings: one is cold installation and the other is hot installation.

1. Cold installation

When installing a small bearing that is not too tight, you can use a sleeve and hammer the sleeve to lightly tap the sleeve to install the bearing in a proper position. When knocking, it should act on the cylindrical roller bearing ring as evenly as possible to prevent the bearing from tilting or skewing. Most cylindrical roller bearings are mounted using the press-fit method. If the inner and outer rings of the cylindrical roller bearing are to be installed on the shaft and the housing at the same time, it must be ensured that the same pressure acts on the inner and outer rings at the same time, and must be on the same plane as the contact surface of the installation tool.

2. Hot installation

Typically, installation of larger bearings is not possible without heating the bearing or housing, because as size increases, more force is required to install. The temperature difference between the cylindrical roller bearing ring and the shaft or housing required for hot mounting depends primarily on the interference and the diameter of the bearing fit. The heating temperature of the open bearing shall not exceed 120℃. It is not recommended to heat cylindrical roller bearings with seals and dust caps above 80°C (make sure that the temperature does not exceed the temperature allowed by the seals and grease). When heating the cylindrical roller bearing, it should be heated evenly, and there must be no local overheating.

Uses of cylindrical roller bearings: Large and medium-sized motors, locomotives, machine tool spindles, internal combustion engines, generators, gas turbines, gearboxes, rolling mills, vibrating screens, and hoisting and transportation machinery.