Многослойное производство FR4 FPC производители Altium flexible circuit

- Категории: FPC >>>

- Поставщик: Jinhua,Technology,(Shenzhen),Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Multilayer FR4 FPC fabrication Altium flexible circuit pcb assembly manufacturers

Over 13 years’experiences on PCB Board

1.Fast and one-stop service

2.Accept PCB design and OEM/ODM service

FPC can be bent, rolled and folded freely without affecting signal transmission.

FPC has many advantages such as space saving, weight reduction, high flexibility, anti-static interference, etc.The structure of the flexible board is divided according to the number of layers of conductive copper foil, which is divided into single-sided boards, double-sided boards, multilayer boards, etc.

Flexible circuit boards are widely used in watches, computers, notebook computers, electronic products, cameras, cameras and other fields

| FPC Process Capability List | |||

| Items | Content | Development Ability | Mass Production Capacity |

| 1 | Product Type | (Double/multilayer) high-density multilayer board, rigid-flex board, RF antenna board | (Double/multilayer) high-density multilayer board, rigid-flex board, RF antenna board |

| 2 | Layer | 1-20L | 1-14L |

| 3 | Finished board size (Max) | 250*650 | 250*500 |

| 4 | Board thickness(Min-Max) | 0.08mm-3.0mm | 0.08mm-3.0mm |

| 5 | Finished product thicknedd tolerance | ±0.015mm | ±0.03mm |

| 6 | Copper foil thickness (Min-Max) | 1/3oz-4oz | 1/3oz-2oz |

| 7 | Insulation thickness (Min-Max) | 0.06mm-3.0 | 0.06mm-1.6mm |

| 8 | CNC drill hole diameter (Min) | 0.2mm | 0.2mm |

| 9 | Laser drill nozzle aperture (Min) | 0.1mm | 0.1mm |

| 10 | Aperture tolerance (plated through hole) | ±0.075mm | ±0.075mm |

| 11 | Tolerance of drilling hole diameter (non-plated through hole) | ±0.05mm | ±0.05mm |

| 12 | Hole position tolerance (compared with CAD number) | ±0.1mm | ±0.1mm |

| 13 | Aperture tolerance (plated through hole) | ±0.075mm | ±0.075mm |

| 14 | Tolerance of drilling hole diameter (non-plated through hole) | ±0.05mm | ±0.05mm |

| 15 | Hole position tolerance (compared with CAD number) | ±0.1mm | ±0.1mm |

| 16 | PTH hole wall copper thickness | ≥0.01mm | ≥0.01mm |

| 17 | Line width/spacing (minimum) | 0.05mm/0.05mm(1/3oz Copper foil) | 0.05mm/0.05mm(1/3oz Copper foil) |

| 18 | Pad design (minimum) | 0.23mm | 0.3mm |

| 19 | Gold finger width (minimum) | 0.05mm | 0.075mm |

| 20 | Gold finger spacing (minimum) | 0.05mm | 0.075mm |

| 21 | BGA pad (minimum) | 0.23mm | 0.3mm |

| 22 | Minimum center distance between BGA pads | 0.5mm | >0.5mm |

| 23 | Punching hole diameter tolerance | ±0.05mm | ±0.05mm |

| 24 | Via hole and via hole spacing | ≥0.1mm | ≥0.1mm |

| 25 | Green minimum opening | 0.075mm | 0.075mm |

| 26 | The minimum distance from the green window to the edge of the line | 0.075mm | 0.075mm |

| 27 | Minimum distance from line to board edge | Character height0.8mm/Word width0.13mm | Character height0.8mm/Word width0.13mm |

| 28 | Thermosetting white oil overprint tolerance | ±0.2mm | ±0.2mm |

| 29 | Etching tolerance | ±5% | ±15% |

| 30 | Minimum width of photosensitive green oil bridge | 0.125mm | 0.125mm |

| 31 | Minimum width of thermoset white oil bridge | 0.4mm | 0.4mm |

| 32 | ENIG | Gold thick/AU:0.025-0.125um Nickel thickness/Ni:1-4um | Gold thick/AU:0.025-0.125um Nickel thickness/Ni:1-4um |

| 33 | Immersion Tin | Sn:0.025-0.125um | Sn:0.025-0.125um |

| 34 | OSP | 0.1-0.5um | 0.1-0.5um |

| 35 | Pure tin spray | 1-40um | 1-40um |

| 36 | HAL Leaded | 1-40um | 1-40um |

| 37 | Immersion Sliver | ≥0.15um | ≥0.15um |

| 38 | Punching shape tolerance (laser cutting) | ±0.05mm | ±0.05mm |

| 39 | Punching shape tolerance (slow-moving wire steel die) | ±0.05mm | ±0.05mm |

| 40 | Punching shape tolerance (fast-moving wire steel die) | ±0.1mm | ±0.1mm |

| 41 | Finished board impedance control | ±10% | ±10% |

| 42 | Finished product short-circuit test | 288±5℃/10S/3T/No delamination/foaming | 288±5℃/10S/3T/No delamination/foaming |

| 43 | Solderability test of finished product | 245±5℃/3-5S/Semi-humid≤3% | 245±5℃/3-5S/Semi-humid≤3% |

| 44 | Peel strength of finished product | ≥0.8kg/cm | ≥0.8kg/cm |

| 45 | Ion contamination test of finished product | ≤3ug/inch2 | ≤3ug/inch2 |

| 46 | Finished product aging | 72H,70℃ | 72H,70℃ |

Jinhua factory can meet differnt PCB material requirments

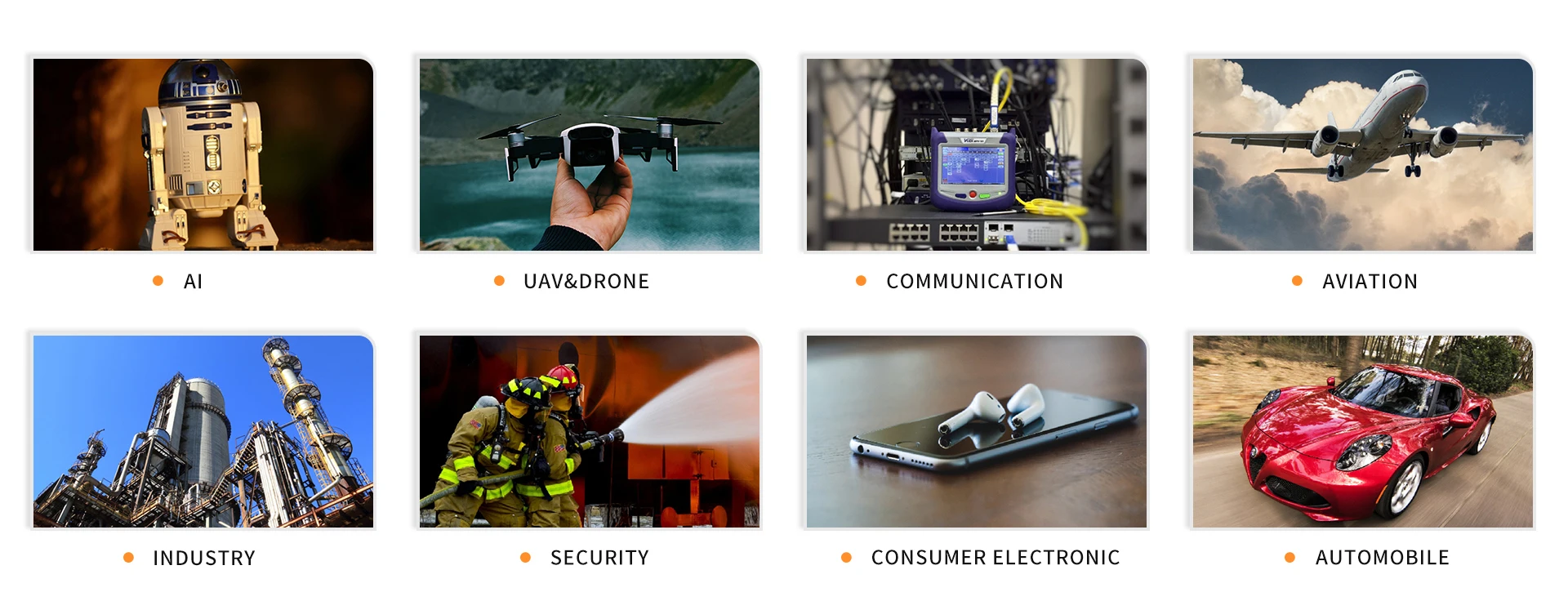

Jinghua Technology’PCB Boards are mainly used in the field of smart electronics, AI consumer electronics,

medical and healthcare, home appliance, automobile, and so on.

Welcome to visit out factory and contact us for new projects!

Bubble package, EPE package, ESD Bag,Vacuum bag

Delivery

Q1. What does Jinhua Tecenology can do?

We can support you PCB Design, PCB board manufacturing, Components or Parts Source, Surface Mount (SMT), Thru-Hole (THT),hybrid of both, Functional Test, Wire Soldering etc one stop PCB&PCBA service

Q2. What is needed for quotation?

Gerber file and Technic requirements (material, surface finish treatment, copper thickness, board thickness, and so on.)

Q3. What file formats do you accept for production?

Gerber Files+BOM File+Centroid File(other names maybe:aka Insertion, Pick-N-Place, or XY Data)

Q4. Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers in the whole process. All documents from customers are never shared with any third parties.

Q5. MOQ?

There is no MOQ in Jinhua Tecenology. We can offer prototype, expedite prototype, small&medium amount, big amount pcb & pcba service

Q6. How does your factory make the Quality Control? Three main parts to control products' quality as bellow,

1. IQC-incoming inspection for materials

2. IPQC-process inspection

3. FQC-finished products inspection It has standards and reports for each part of inspection, also it is strict for selecting material suppliers.

Q7. What payment methods do you accept?

T/T, West Union,Money gram and L/C are accepted, for samples PayPal. FOB, CIF, DDU and Ex-work are accepted.