DZJX химическая НЕОБРАБОТАННАЯ металлическая пудра небольшая Поворотная стакан оборудование для просеивания машина сортировки

- Категории: >>>

- Поставщик: Xinxiang,Dongzhen,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Raw Metal Powder Chemical Particle Cocoa Bean Sifter Swing Tumbler Vibratory Shaking Screen Vibro Sieve Sieving Machine

DZYS series tumbler screen machine is a kind of inertial equipment with mature technology and classical application. Its new design and unique structure make it the closest manual screen machine. The Tumbler sieve machine have bright application prospects for its perfect screening effect. From the aspect of its trajectory, it is a non-linear inertial vibrating screen.

The Tumbler screen is particularly used to classify small materiels and fine powder according to its unique structure and working principle. It is not only apply to dry sieving, but also wet sieving.It is widely used in mine, building material,metallurgy,foundry, abrasive material, chemical, light industry, medical, food and other industry.

* Ultrasonic Cleaning System

* Large Output and Safe Operation

* High Screening Accuracy

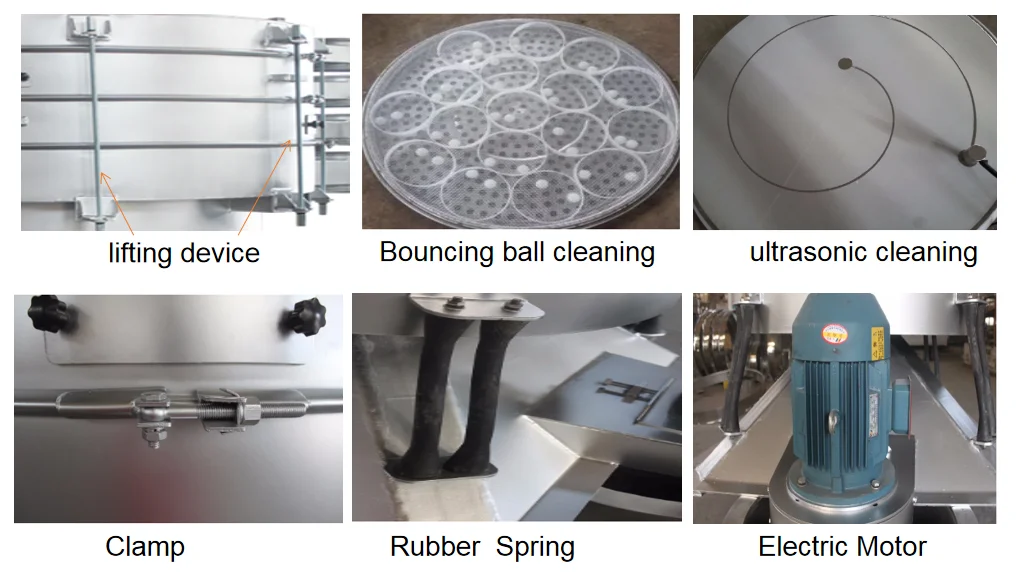

Product structure

Details Images

Products show

Customer photos

Technical parameter

Model | Mesh zrea(㎡) | Granularity(mm) | Amplitude(mm) | Power(kw) |

DZYS-600 | 0.28 | ≤100 | 20-70 | 0.75 |

DZYS-1000 | 0.66 | ≤100 | 20-70 | 1.5 |

DZYS-1200 | 0.98 | ≤100 | 20-70 | 2.2 |

DZYS-1500 | 1.67 | ≤100 | 20-70 | 3.0 |

DZYS-1800 | 2.37 | ≤100 | 20-70 | 4.0 |

DZYS-2000 | 2.89 | ≤100 | 20-70 | 4.0 |

DZYS-2600 | 5.3 | ≤100 | 20-70 | 5.5 |

Application

--Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, etc

--Abrasive material and ceramic industry: building sand, alumina, silica sand, abrasive, refractory material, slurry, etc.

--Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, metal powder, etc

--Food industry: sugar, salt, alkali, flour powder, farina, gourmet powder, starch, milk powder, yeast powder,etc

--Abrasive material and ceramic industry: building sand, alumina, silica sand, abrasive, refractory material, slurry, etc.

--Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, metal powder, etc

--Food industry: sugar, salt, alkali, flour powder, farina, gourmet powder, starch, milk powder, yeast powder,etc

Customized service

According to the needs of the buyer, the number of swing screen layers can be customized. At present, our factory supports the customization of one to four layer swing screen.

Stainless steel material is the first choice for medical grade and food grade buyers, carbon steel is the first choice for cost saving, contact with stainless steel can not only meet the health requirements, but also save costs.

Stainless steel material is the first choice for medical grade and food grade buyers, carbon steel is the first choice for cost saving, contact with stainless steel can not only meet the health requirements, but also save costs.

Packing & Delivery

Our Company

FAQ

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size,capacity(kg/h),granularity distribution is recommended. product material requirement (Q235A, SUS304 or SUS316,etc.) Voltage & Frequency(Hz)

A: Material bulk density, mesh size,capacity(kg/h),granularity distribution is recommended. product material requirement (Q235A, SUS304 or SUS316,etc.) Voltage & Frequency(Hz)

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry. With our experienced quality control team, we are trying to offer most of our customers the product with best quality. However, we do recognized that there are small amount of the product which may get faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Related Products

Похожие товары

Оборудование для линейного вибрационного сита из нержавеющей стали

9 300,00-10 000,00 $

Электровибрационный питающий конвейер и вибрационный экран

3 200,00-3 500,00 $